Fully Automatic Intelligent for Vertical Packaging Machine

Friday July-05 2024 17:06:54

What is a fully automatic intelligent vertical packaging machine?

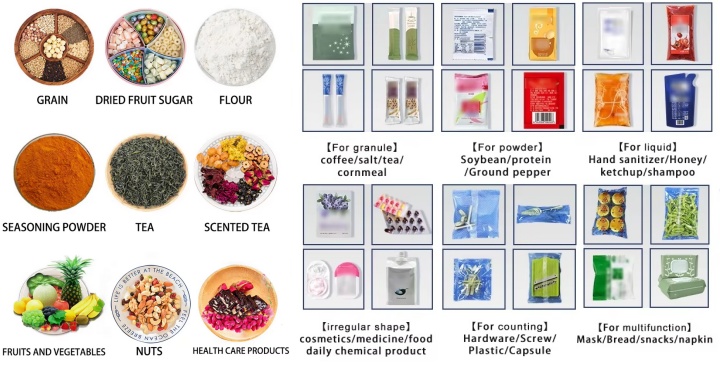

Fully Automatic Intelligent for Vertical Packaging Machine automatically complete all packaging processes. It has the characteristics of high efficiency, reliability, simple structure, etc. vertical packaging machine is widely used in various products such as cakes, bread, ointments, meat products, vitamins, etc.

What are the benefits of a fully automatic intelligent vertical packaging machine?

Fully automatic operation: The vertical packaging machine adopts fully automatic operation, without manual intervention, improving production efficiency and reducing labor costs.

Vertical structure: This model adopts a vertical structure design, with a small footprint, suitable for production environments with limited space.

Versatility: It can adapt to packaging of different types and sizes, with adjustable packaging speed and packaging specifications.

High-precision metering: Equipped with a precise metering system, it can accurately control the amount of packaging materials to ensure the accuracy and consistency of packaging.

Intelligent control: It can monitor and adjust each working link to achieve automatic fault detection and alarm.

Multiple safety protections: Such as preventing overload, overheating and missing packaging materials, etc., to ensure the safety of operators and equipment.

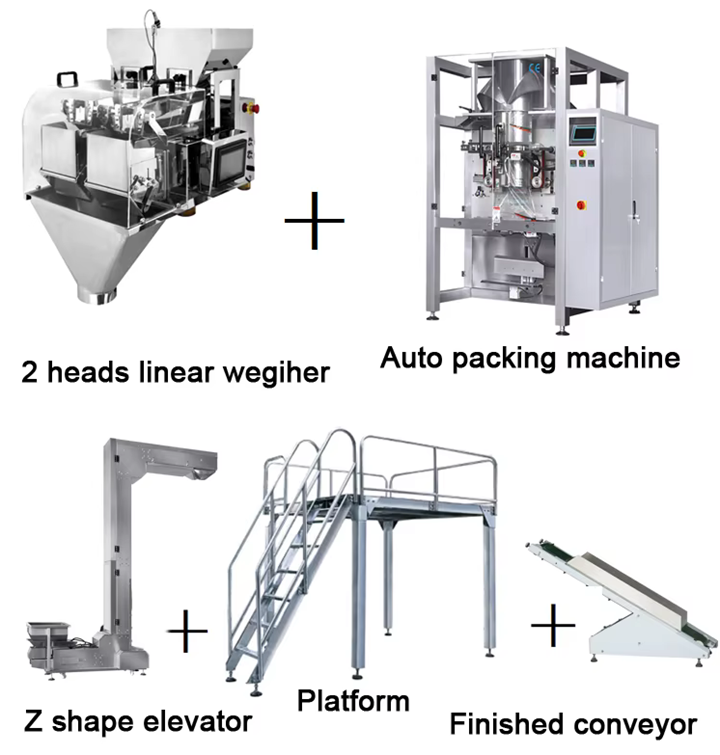

Fully automatic intelligent vertical packaging machine structure

Feeding system: used to transport the product to be packaged to the workbench or conveyor belt of the packaging machine to start the packaging process.

Metering system: Metering and quantitative delivery are carried out according to the specifications and requirements of the product to ensure the accurate number of products in each packaging bag.

Packaging bag making system: Make packaging bags and position them, usually through a film roll machine to make a roll film, and then cut it into packaging bags of the required length through a bag cutting device.

Filling system: Fill the product into the packaging bag in different ways.

Sealing system: Seal the packaging bag filled with the product, usually by heat sealing or pressing, to ensure that the product in the packaging bag will not leak or be contaminated by the outside world.

Cutting system: Cut and position the sealed packaging bag to prepare for the next round of packaging.

Control system: The operation of the entire packaging machine and the coordinated work of each component are controlled and monitored by the control system, usually using a PLC control system or a touch screen control panel.

Safety protection device: In order to ensure the safety of the operator, the packaging machine is usually equipped with safety protection devices, such as safety doors, emergency stop buttons, etc.

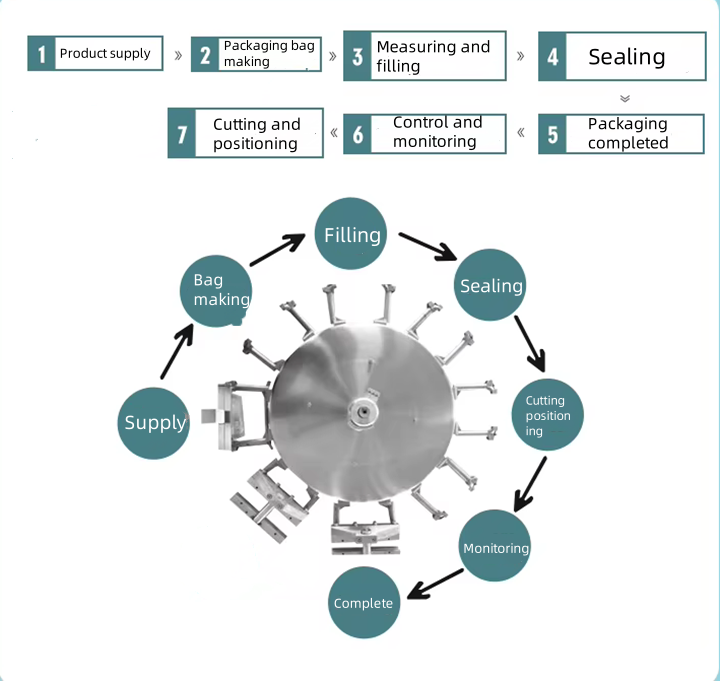

How does the automatic intelligent vertical packaging machine work?

-Product supply: The product is conveyed to the workbench or conveyor belt of the packaging machine through the feeding system.

-Packaging bag making: Cut the required length of packaging bags from the roll film and position them to be filled.

-Measuring and filling: The product is measured by the metering system and then filled into the packaging bag.

-Sealing: The filled packaging bag is sealed by the sealing system, usually by heat sealing or pressing.

-Cutting and positioning: The sealed packaging bag is cut by the cutting system, and the packaging bag to be taken out is positioned to prepare for the next round of packaging.

-Control and monitoring: The operation of the entire packaging machine and the coordinated work of each component are controlled and monitored by the control system.

-Packaging completed: After the above steps, the product is packaged and can be sent out of the packaging machine by conveyor belt or other means to prepare for the next processing or packaging.

Which industry should give priority to fully automatic intelligent vertical packaging machines?

Food industry: The food industry is one of the industries with the most extensive application of packaging machines. Fully automatic intelligent vertical packaging machines can improve packaging efficiency, maintain food quality and hygiene.

Pharmaceutical industry: The pharmaceutical industry has very strict requirements for product packaging. Fully automatic intelligent vertical packaging machines can ensure the accuracy and hygiene standards of drug packaging.

Cosmetics industry: Products in the cosmetics industry usually require exquisite packaging. Fully automatic intelligent vertical packaging machines can provide efficient and accurate packaging solutions.

Daily chemical products industry: The production of daily chemical products such as detergents and personal care products usually requires a large amount of packaging. Fully automatic intelligent vertical packaging machines can improve production efficiency.

Electronic products industry: Electronic products usually require precision packaging. Fully automatic intelligent vertical packaging machines can ensure the safety and integrity of product packaging.

Agricultural industry: The packaging of agricultural products can also be automated through fully automatic intelligent vertical packaging machines to improve packaging efficiency and product quality.

Industrial products industry: The packaging of industrial products usually requires durable and safe packaging methods. Fully automatic intelligent vertical packaging machines can provide packaging solutions that meet the requirements.

Fully automatic intelligent for vertical packaging machine price

The price of a fully automatic intelligent vertical packaging machine depends on many factors, including manufacturer, model, specifications, functions, production capacity, degree of automation, etc. Generally speaking, the price range of a fully automatic intelligent vertical packaging machine is very wide, which may range from a few thousand dollars to hundreds of thousands of dollars. If you want to get the latest quotation information, you can contact us directly!