What is a multihead packaging machine?

Multihead Packaging Machine, also known as a multihead weigher or combination weigher, is a specialized packaging equipment commonly used in the food industry for efficient and accurate weighing and packaging of products. It is designed to handle multiple product streams simultaneously and provide precise dosing of products into individual packages.

Multihead packaging machine, also known as a multihead weigher or combination weigher, is a specialized machine used for high-speed weighing and packaging of various products. It is commonly used in the food industry for packaging items such as snacks, confectionery, grains, nuts, frozen foods, and more.

Quality multihead packaging machine for sale

Each model of multihead weighing packaging equipment is suitable for packaging bags of different widths, so it can meet the packaging needs of products of different specifications. Products from small to large specifications can be packaged and produced by these equipment.

TH-420: Suitable for packaging bags with a width of 50-200mm, such as small packages of snacks, seasonings, foundation, etc.

TH-520: Suitable for packaging bags with a width of 80-250mm, such as instant beverage powder, flour, mask powder, and medicine powder.

TH-720: Suitable for packaging bags with a width of 180-350mm, such as large packages of instant beverage powder, bath salts, etc.

Live Video

Various applications of multihead packaging machine

Multihead packaging machine is perfectly applied for packaging various foods, medicines, industrial components, and other granular items. Applicable granular food includes puffed food, coffee beans, peanuts, melon seeds, candy, dry fruit, red dates, snacks, grains, popcorn, oatmeal, chips, shrimp strip, prawn cracker, onion rings, rice crust, etc. For puffed food, you can choose a nitrogen filling device to exhaust the air in the packaging bag in order to extend storage time and keep the taste.

The packaging weight can be up to 3kg per bag. The equipment with multiple heads works efficiently and accurately, and the error is less than one gram.

How does multihead packaging machine work?

A multihead packaging machine, also known as a multihead weigher, is a sophisticated piece of equipment that streamlines the packaging process. It operates by utilizing multiple weighing heads, each equipped with a load cell, to accurately measure the weight of products. The machine's computerized control system calculates the optimal combination of weights from the hoppers to achieve the desired target weight for each package. Once the products are weighed, they are evenly distributed into individual packaging units through a distribution system. With high-speed weighing capabilities, flexibility to handle various products, and integration with other packaging equipment, the multihead packaging machine ensures efficient and precise packaging operations, contributing to increased productivity and consistent packaging quality.

Multihead packaging machine specifications

| Type | TH420 | TH520 | TH720 |

| Bag length | 80-300mm | 80-400mm | 100-400mm |

| Bag width | 50-200mm | 80-250mm | 180-350mm |

| Max width of roll film | 420mm | 520mm | 720mm |

| Packing speed | 5-30bags/min | 5-50bags/min | 5-50bags/min |

| Air consumption | 0.65mpa | 0.65mpa | 0.65mpa |

| Gas consumption | 0.3m³/min | 0.4m³/min | 0.4m³/min |

| Power voltage | 220V | 220VAC/50HZ | 220VAC/50HZ |

| Dimension | (L)1320*(W)950*(H)1360 | (L)1150×(W)1795×(H)1650mm | (L)1780×(W)1350×(H)1950mm |

Features of multihead packaging machine

1. Multi-Head Design: The defining characteristic of these machines is their multiple weighing heads, typically ranging from four to sixteen. Each head acts independently, simultaneously weighing and dispensing products into containers. This parallel operation significantly increases packaging speed and efficiency.

2. Accurate Weighing: Each weighing head incorporates high-precision load cells to ensure accurate product dispensation. This precision is crucial for products sold by weight, such as dry foods, nuts, and confectionery items.

3.Speed and Efficiency: Multihead packaging machines excel in speed due to multiple weighing heads working concurrently. This feature reduces packaging downtime and allows for high production outputs, maximizing packaging efficiency.

4.Versatile Product Handling: Multihead packaging machines can handle a wide variety of products, ranging from small granules to bulky items. They are suitable for products with different shapes, textures, and flow characteristics.

5.Compact Design: Despite their multiple weighing heads and advanced functionality, these machines are designed to be compact and space-saving. They can easily fit into production lines with limited space availability.

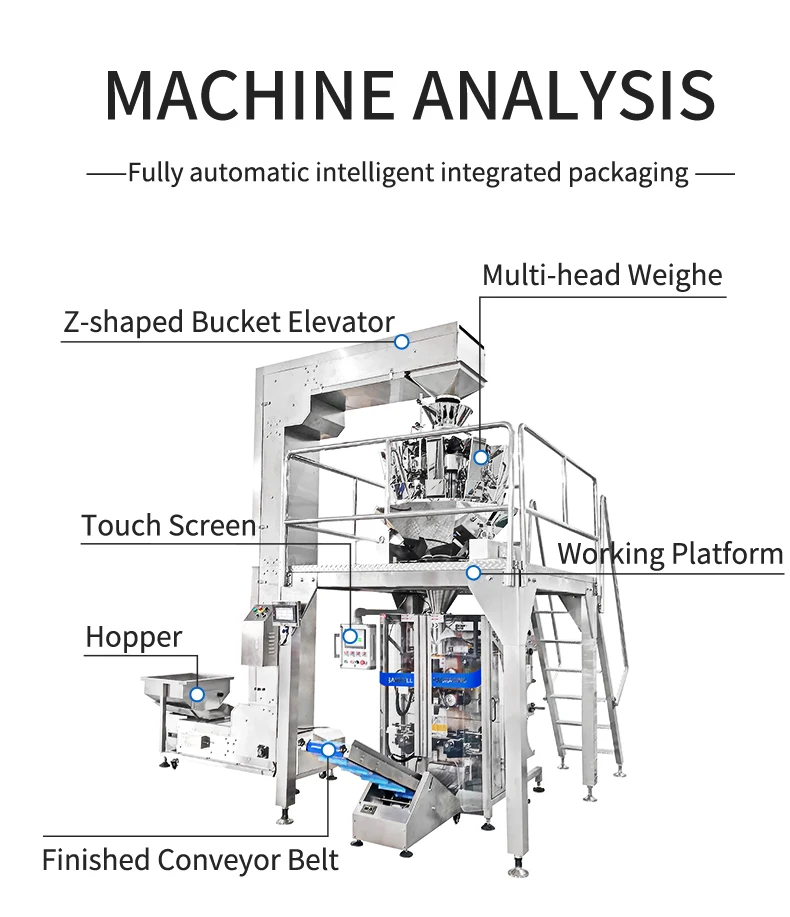

Structure of multihead packaging machine

The multi-head packaging machine is composed of several main parts. Its working principle is inseparable from the joint operation of each component. The following is the general structure and main components of the multi-head packaging machine:

Frame: The machine's frame provides structural support and stability. It is usually made of durable materials such as stainless steel or aluminum to ensure longevity and hygiene.

Hopper System: The machine consists of multiple hoppers, usually ranging from 8 to 32 hoppers, depending on the model. Each hopper holds a specific product or ingredient to be weighed and dispensed. The hoppers are often transparent or equipped with sensors to monitor product levels.

Weighing Heads: The machine features multiple weighing heads, typically corresponding to the number of hoppers. Each weighing head contains a load cell or weighing sensor that measures the weight of the product in the respective hopper. The load cells convert the weight into electrical signals for further processing.

Distribution System: The machine employs a distribution system to evenly distribute the weighed product into individual packaging units. This system can include vibrating feeders, rotary feeders, or other mechanisms that transfer the product from the hoppers to the packaging containers, such as bags, pouches, or containers.

Conveyor System: A conveyor system is often integrated into the multihead packaging machine to transport the packaging containers to the distribution point and carry them away after filling. This facilitates a continuous flow of containers throughout the packaging process.

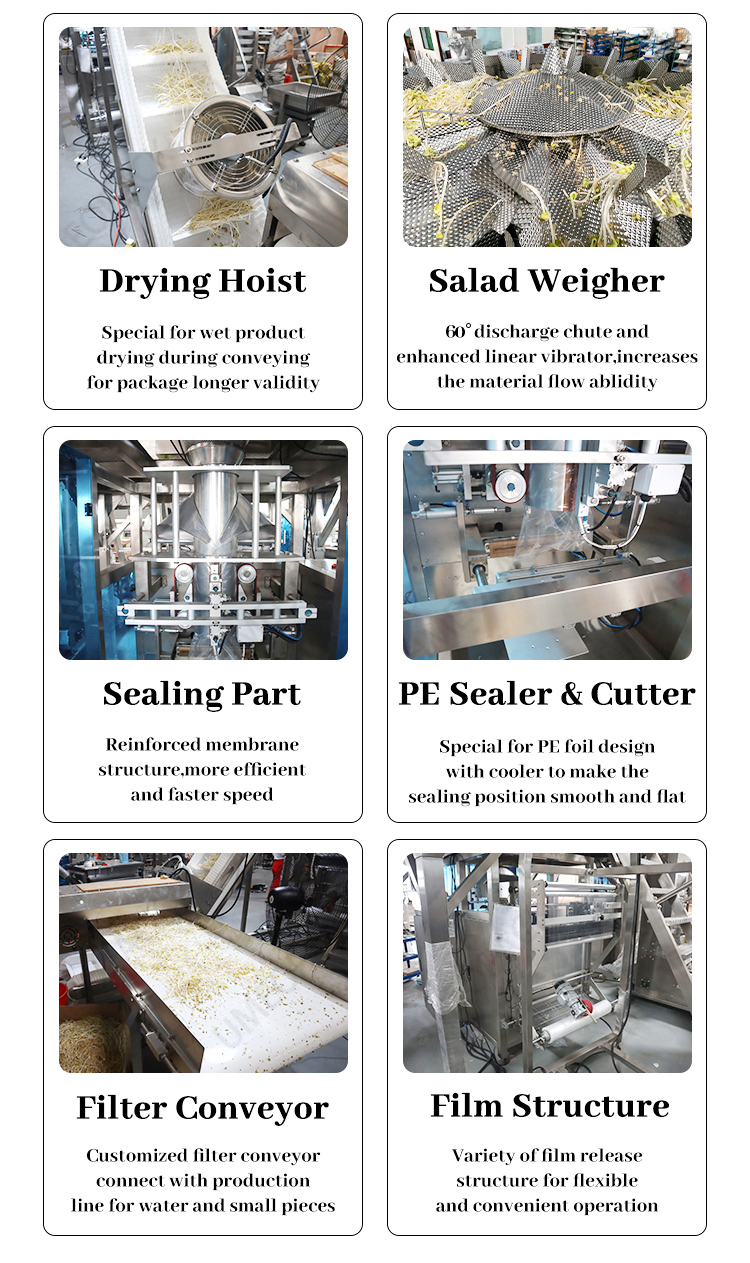

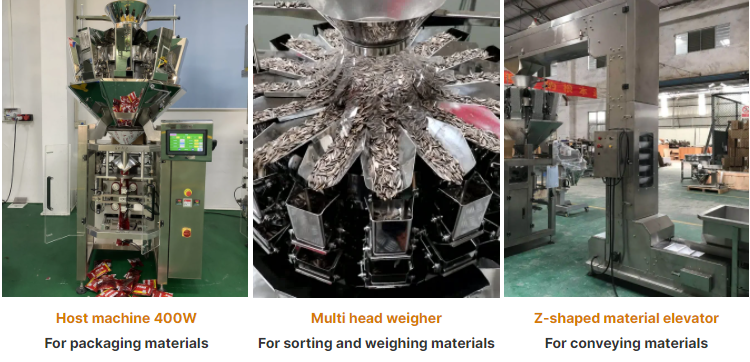

Main parts of multihead packaging equipment show

The design and function of each component of the multi-head packaging machine are to achieve the smooth progress of the overall production process. The following is a display of the main components of this packaging machine.

Drying elevator: dedicated to drying during the conveying process of wet products to extend the shelf life of packaging.

Sealing part: reinforced membrane structure, higher efficiency and faster speed.

Filter conveyor: customized filter conveyor connected to water and small parts production line.

Salad mixer: 60°discharge chute and enhanced linear vibrator to improve material flow capacity.

PE sealer and cutter: specially designed for PE foil, with cooler to make the sealing position smooth and flat.

Film structure: a variety of film release structures, flexible and convenient operation.

Customer case

| Packaging Case | application | Results |

| A large snack manufacturer | For packaging nuts and dried fruits. | By introducing the Multihead Packaging Machine, packaging speed has increased by 50%, while material waste has been reduced, and production efficiency and product consistency have been improved. |

| A pharmaceutical company | For packaging tablets and capsules. | A packaging accuracy of up to 99% is achieved, ensuring the accurate dosage of each package in compliance with pharmaceutical production standards, reducing manual intervention and improving overall production efficiency. |

| A fertilizer production company | For packaging granular fertilizers | The introduction of the multi-head packaging machine has increased the efficiency of the production line by 40%, and can adapt to fertilizers of different particle sizes, meeting the diverse needs of the market. |

| A detergent manufacturer | Used for packaging washing powder and liquid detergent. | Through automated packaging, packaging time and labor costs are reduced, while the appearance consistency of the product is improved and the brand image is enhanced. |

How to choose multihead packaging machine?

When choosing a multi-head packaging machine, we can consider the production speed, product characteristics and product size of the product.

1. Product Characteristics: The characteristics of the product being packaged play a vital role in selecting a suitable multi-head packaging machine. Factors to consider include product size, shape, flowability and brittleness.

2. Packaging form: The choice of packaging form, whether it is a bag, pouch, carton or other container, will affect the requirements of the machine.

3. Production Capacity: Determine the required production output to ensure the machine's speed and efficiency meet your specific needs.

4. Hygiene Requirements: For food and pharmaceutical applications, it is crucial to select machines that meet strict hygiene standards.

5. Maintenance and Service: Consider the availability of spare parts and the availability of qualified technicians for maintenance and troubleshooting.

Multihead Weigher packing machine Price

Dahan multi-head packaging machine is committed to providing innovative packaging solutions for customers around the world. We use the most advanced technology, including a precise multi-head weighing system and an intelligent control system to ensure the accuracy and consistency of each package. We can provide customers with customized packaging solutions and design and adjust the equipment according to customer needs. The price is generally between $790.00-$12,600.00. If you also have packaging needs, please contact us and we will provide you with a detailed introduction and quotation!