What is a fully automatic packaging machine?

Fully Automatic Packaging Machine is a kind of equipment that automates the entire packaging process, which can efficiently and accurately package various products such as food, beverages, medicines, cosmetics, etc. Compared with semi-automatic or manual packaging methods, fully automatic packaging machines have high-speed production, consistent packaging quality and higher efficiency.

Functions of fully automatic packaging machine

Fully automatic packaging machines are highly efficient and intelligent packaging equipment, which are often used in production lines in various industries. The following are common functions of fully automatic packaging machines:

Automatic packaging: It can automatically complete the entire packaging process, from bag forming, product filling, sealing to cutting and separation.

Precise metering: It ensures that the product dosage in each packaging bag is accurate and avoids waste and variation.

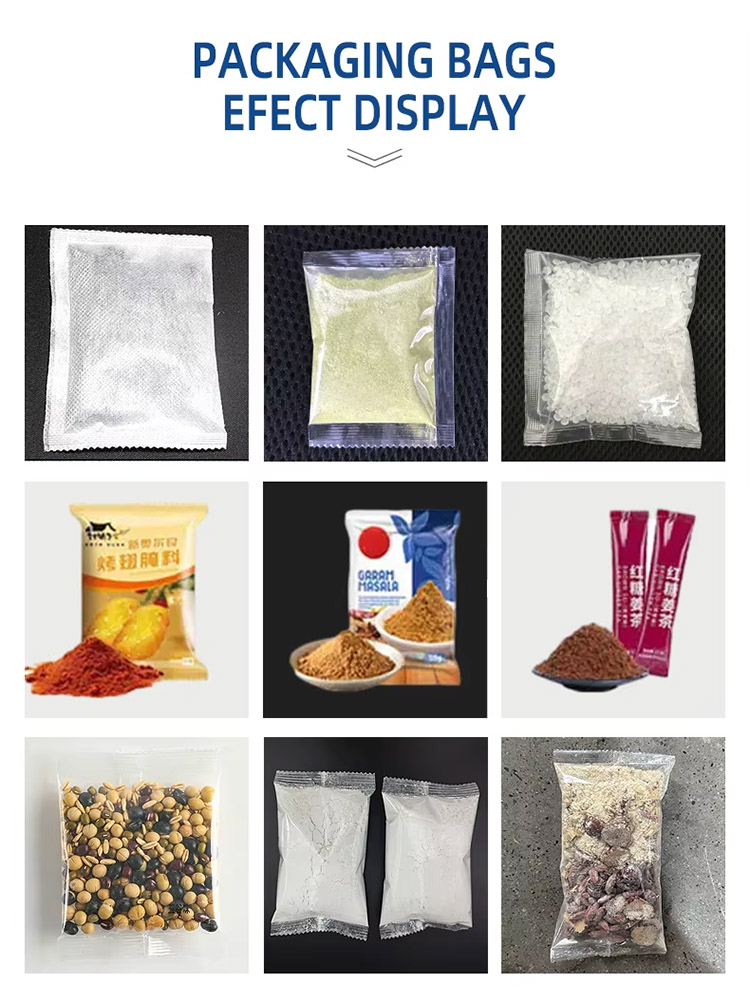

Versatility: It has a variety of packaging functions and can adapt to packaging bags of different shapes, sizes and types.

Quick changeover: It has the function of fast changeover and can be quickly adjusted as needed to adapt to the packaging requirements of different products.

Automatic detection and error correction: Fully automatic packaging machines are usually equipped with sensors and automatic control systems that can detect problems in the packaging process, such as empty bags, wrong sealing, etc., and automatically correct them or issue alarms.

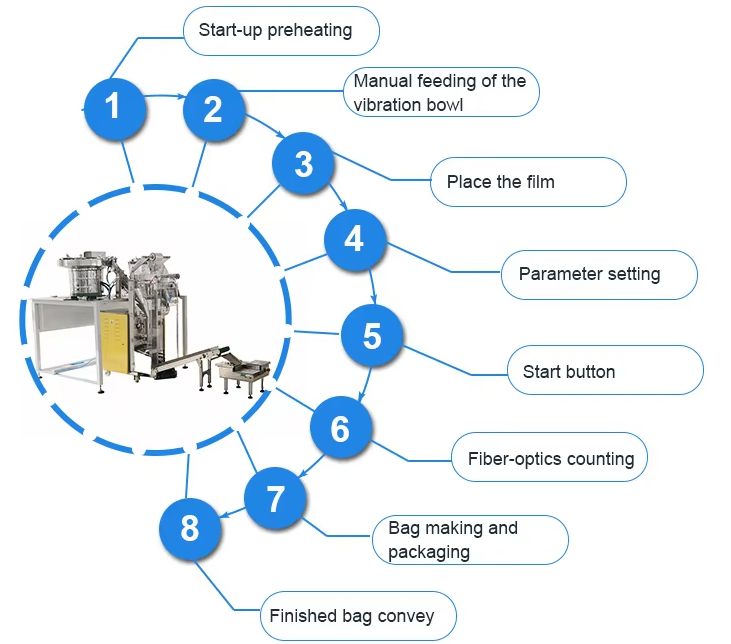

How does a fully automatic packaging machine work?

During the operation of the fully automatic packaging machine, a certain length of film is first pulled out from the roll of packaging film, and then formed into a tubular bag and sealed longitudinally at the bag forming station. The product is then accurately filled into the bag, and the bag is then moved to the sealing station for sealing. Finally, the bag is cut into individual bags and separated from the remaining film at the cutting and separation station. The finally packaged bagged product is moved out of the packaging machine and is ready for further processing, storage or transportation.

Customer Cases

Features of fully automatic packaging machine

Improve production efficiency: The equipment can work continuously, greatly improving production efficiency and reducing labor costs.

Ensure packaging quality and consistency: The equipment can automatically complete weighing, bagging, sealing and other operations to ensure packaging quality and consistency.

Easy to operate: Fully automatic peanut packaging machines are usually equipped with intelligent control systems that are simple and easy to operate.

Customizable: Equipment with different specifications and functions can be customized according to customer needs to meet different production needs.

Easy to maintain and maintain: The equipment has a simple structure and is easy to maintain and maintain, reducing operating costs.

Difference between fully automatic packaging machine and semi-automatic packaging machine

The main difference between fully automatic and semi-automatic packaging machines is the level of automation and manual intervention required during the packaging process. Here are the main differences:

1. Level of automation: Once set up and running, a fully automatic packaging machine can operate with little or no manual intervention. Semi-automatic packaging machines require manual intervention at all stages of the packaging process.

2. Function: The fully automatic packaging machine can handle a variety of packaging tasks, including product feeding, filling, sealing, labeling and quality control, without manual assistance. Semi-automatic packaging machines often automate specific packaging tasks, such as filling or sealing, while requiring manual loading, unloading or adjustment of packaging materials.

3. Speed and efficiency: Fully automatic machines are designed for high-speed operation and can handle large quantities of products in a shorter time, thereby increasing productivity and efficiency. Semi-automatic machines are typically slower than fully automatic machines because they rely on human operators to complete certain tasks.

4. Cost: Due to their advanced functions and higher automation level, fully automatic packaging machines often have higher initial investment costs compared with semi-automatic machines.

Fully automatic packaging machine specifications

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

Application fully automatic packaging machine

Fully automatic packaging machines are widely used in various industries, especially in production environments that require efficient and precise packaging. The following are some of the application areas of fully automatic packaging machines:

Food and beverage industry: used in the food and beverage industry, such as packaging potato chips, candies, coffee, tea, beverages, etc.

Pharmaceutical and medical device industry: used to package tablets, capsules, syringes, medical devices and other products.

Daily chemical products industry: can be used for packaging, detergents, shampoos, skin care products and other daily chemical products.

Household products industry: used in the household products industry, such as packaging paper towels, cleaning utensils, aromatherapy and other products, to improve production efficiency and packaging quality.

Agriculture and horticulture industry: can be used to package fertilizers, seeds, pesticides and other products; in the horticulture industry, it can be used to package flowers, gardening tools, etc.

Electronic products industry: can be used to package mobile phones, tablets, accessories, etc.

Customer case

1. A large food processing company mainly deals in quick-frozen foods, such as dumplings, glutinous rice balls, spring rolls, etc. Due to the growth of market demand, manual packaging can no longer meet production needs. At the same time, labor costs are rising year by year. The company decided to introduce a Fully Automatic Packaging Machine, which can automatically weigh and pack quick-frozen foods. It uses modified atmosphere packaging technology (MAP) to extend the shelf life of products, achieve high-speed sealing, and ensure the sealing of packaging.

Packaging speed increased by 3 times (originally 10 packages per minute by manual, automatic packaging machine can reach 30 packages)

Reduce labor costs (reduced more than 50% of packaging workers)

Reduce food waste (accurate weighing, error control within ±1g)

2. A pharmaceutical company produces capsules and tablets. In the past, semi-automatic packaging was used, which required manual placement of drugs, which had problems such as low efficiency, large errors, and risk of manual contamination. With the improvement of GMP (Good Manufacturing Practice) requirements, the company decided to upgrade the packaging system. , purchased a Fully Automatic Packaging Machine that can automatically arrange capsules and package them into blister plates,

Using photoelectric detection to ensure that each blister contains the correct number of drugs, connecting to the intelligent tracking system to achieve product traceability,

Increase production efficiency by 2.5 times (from 100 plates per minute to 250 plates per minute)

Ensure consistency and qualified rate (automatic elimination of unqualified products)

Comply with GMP standards (reduce manual contact and reduce contamination risks)

3. A large e-commerce platform needs to process hundreds of thousands of orders every day. The traditional method of manually packaging express bags is inefficient and prone to errors. A large number of temporary workers are required during the peak season, which increases labor management costs. The company introduced the Fully Automatic Packaging Machine for express bags, which has automatic code scanning to match orders, printing and labeling, automatic bagging and sealing, and an intelligent sorting system, which is classified by express company

Order processing speed increased by 300% (originally 500 orders per hour, now up to 1,500 orders)

Order accuracy is close to 100% (reducing manual intervention and reducing the rate of wrong orders)

Reduce 80% of packaging workers and save labor costs

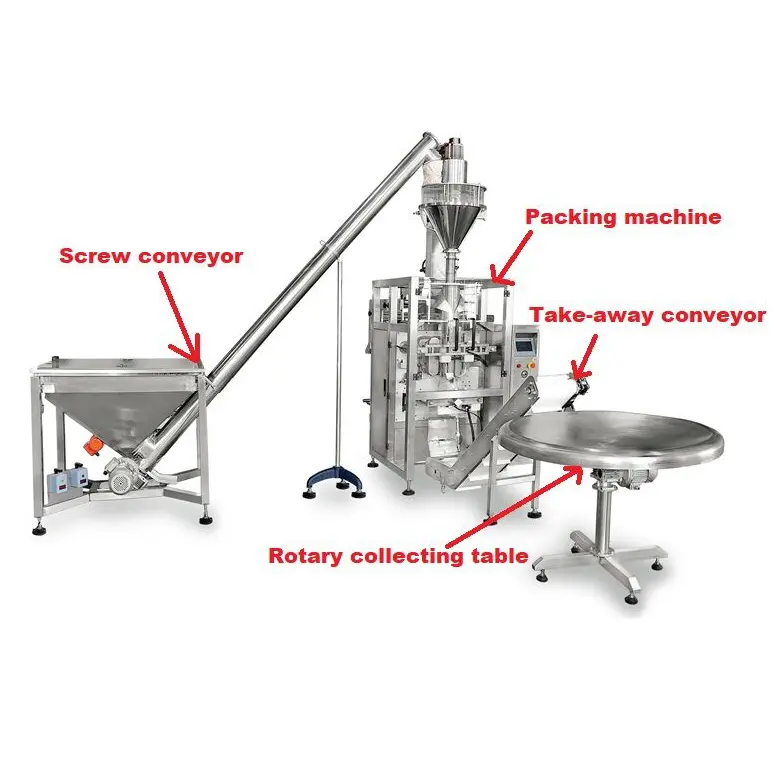

Structure of fully automatic packaging machine

The structural design of the fully automatic packaging machine is aimed at achieving an efficient, precise and stable packaging process, improving production efficiency and ensuring product quality. It usually consists of the following main parts:

Automatic weighing system: used to automatically measure and weigh peanuts to ensure consistent weight of peanuts in each packaging bag.

Bagging system: Put the weighed peanuts into bags and make sure the number of peanuts in each bag is the same.

Sealing system: Seal the peanut bag to ensure the freshness of the product and extend the shelf life.

Printing and labeling system: Print and label labels, including product name, weight, production date and other information, so that consumers can understand the detailed information of the product.

Control system: used to control the operation of the entire equipment, including automated control, safety protection, etc.

Fully Automatic Packaging Machine price

Dahan fully automatic packaging machine has many years of industry experience and technical accumulation. We are committed to providing customers with high-quality and efficient packaging solutions to meet the needs of different industries. We can customize packaging machines of various specifications and functions according to customer needs. The price range generally varies according to the customer's selection needs. We are committed to providing customers with a full range of pre-sales consultation, in-sales technical support and after-sales service to ensure that customers get a satisfactory experience during the purchase and use process. If you are interested in our fully automatic packaging machine products, please feel free to contact our sales team. We will provide you with detailed product information, quotations and technical support to help you find the packaging machine solution that best suits your needs.