What is a pouch packing machine?

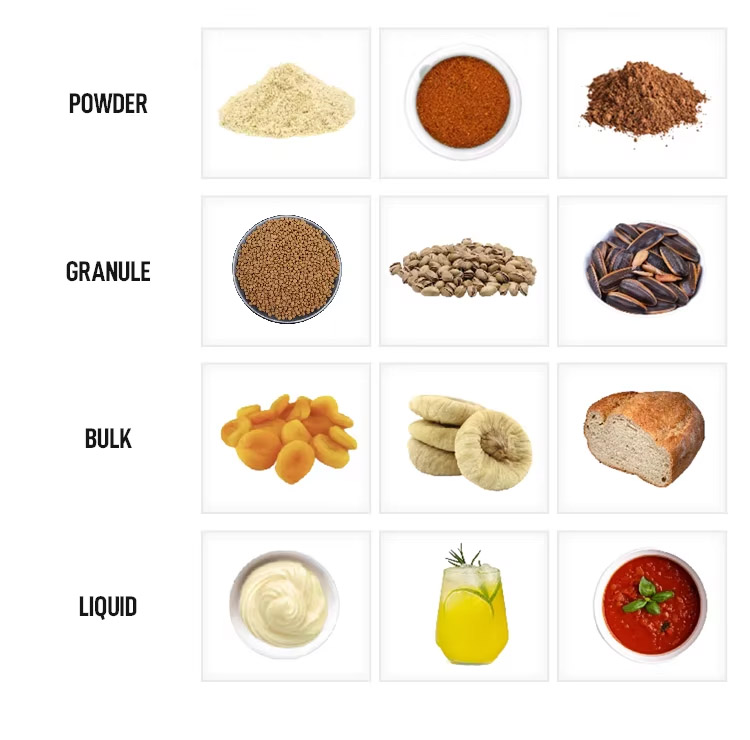

Pouch Packing Machine is an automated packaging device that puts bulk, granular, liquid, powder or even block materials into prefabricated bags. It can automatically complete a series of operations such as bag taking, bag opening, filling and sealing. This packaging method has the advantages of beautiful packaging, good sealing and accurate measurement. It is widely used in many industries such as food, medicine, chemical industry and daily chemicals.

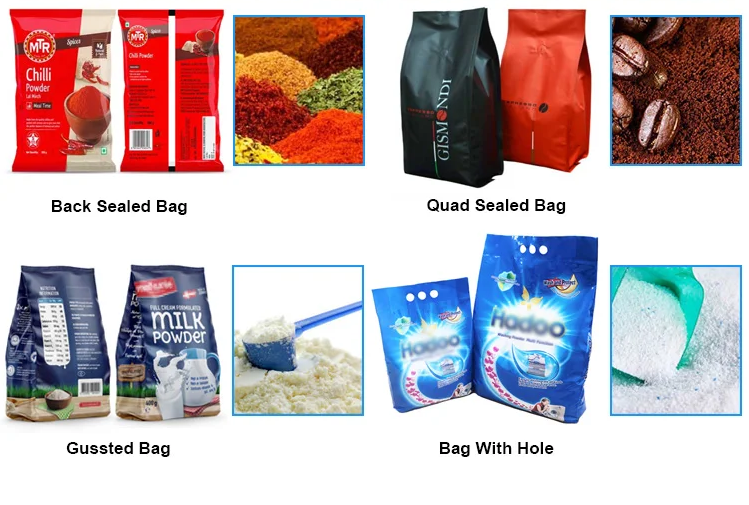

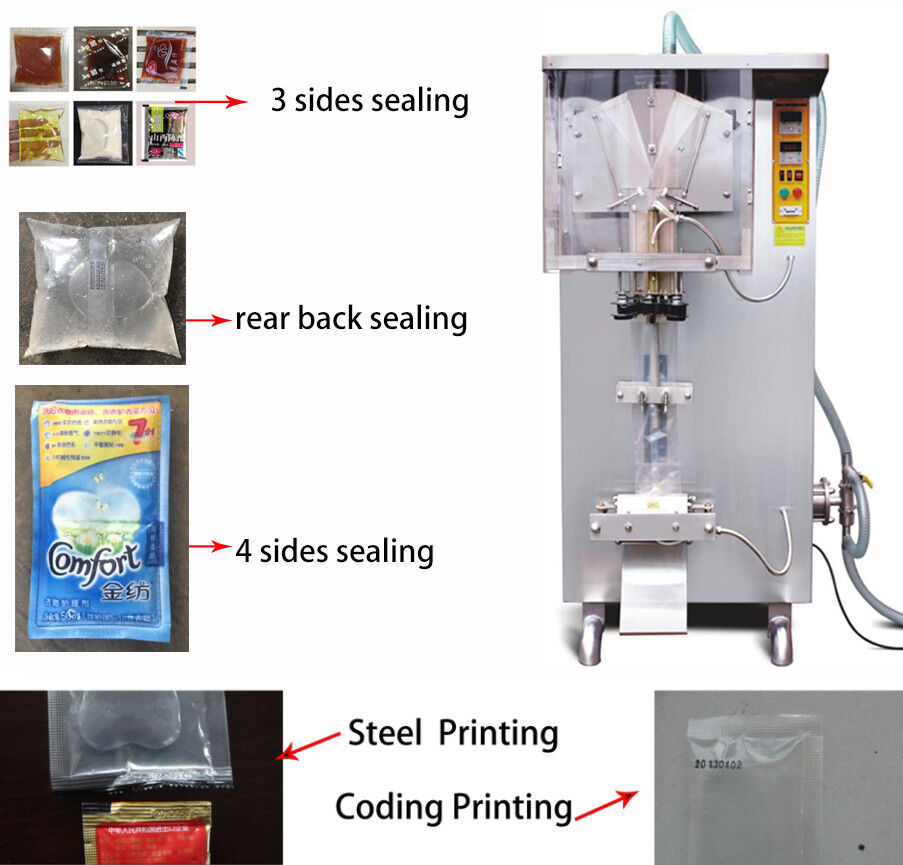

Pouch Packing Machine can efficiently produce various types of flexible packaging bags, including stand-up bags, zipper bags, three-side seal bags, etc. The corresponding packaging bags can be selected according to the type of packaging products.

What are the types of pouch packing machine?

Pouch packing machine has vertical, horizontal, pre-made bag and other classifications, which can be selected according to the packaging of various product types and packaging requirements.

Vertical Form-Fill-Seal (VFFS) Machines: These machines form pouches from a roll of packaging film, fill them with the product, and then seal them. They are suitable for packaging granular, powder, or solid products.

Horizontal Form-Fill-Seal (HFFS) Machines: These machines form pouches in a horizontal orientation, fill them with the product, and then seal them. They are commonly used for packaging liquids, creams, and viscous products.

Pre-made Pouch Packaging Machines: These machines are designed to fill and seal pre-made pouches with the product. The pouches are typically supplied to the machine in a ready-to-use form.

Pouch Packing Machine Video

What are the application scope of bag packaging machine?

Pouch Packing Machine is a multifunctional automatic packaging equipment, which can be used in the food industry to pack snack foods (potato chips, candies, nuts, biscuits), frozen foods (dumplings, glutinous rice balls), condiments (chicken essence, monosodium glutamate), liquid foods (soy sauce, vinegar), powder foods (milk powder, coffee powder); in the pharmaceutical industry to pack granules, powders, tablets, capsules, liquid medicines, etc.; in the cosmetics industry to pack various cosmetics, shampoos, shower gels, skin care products, etc.; in the chemical industry to pack washing powder, fertilizers, pesticides, granular chemical raw materials, etc.

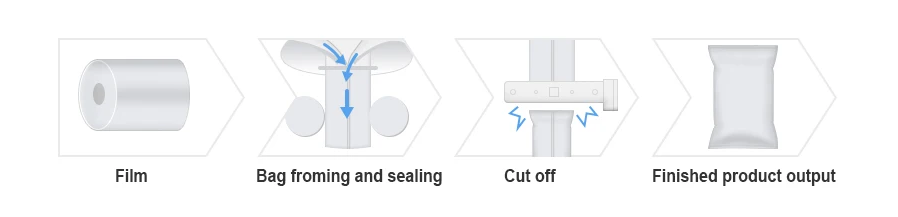

How does a pouch packing machine work?

A bag packaging machine is a device used to automatically put products into bags and seal them. Its working principle usually includes the following steps:

Feeding products: After the pre-processing and preparation stage, the products are conveyed to the feeding system of the packaging machine.

Bag opening: The packaging machine automatically opens and positions the bags to be filled.

Measuring and filling: The products enter the bags from the feeding system according to the set parameters. The metering system is usually used to ensure that the number or weight of products in each bag is accurate.

Sealing and packaging: When the bag contains enough products, the bag will move to the sealing area, which is usually completed by heat sealing, compression or ultrasonic sealing technology.

Discharging finished products: After sealing and labeling, the bag containing the product will be discharged from the packaging machine.

Pouch packing machine specifications

| Sealing Type | 3 side sealing or back sealing | Back sealing |

| Packing Weighting Range | 0-20g,0-50g,0-100g | 0-100g,0-200g,50-1000g,100-2000g |

| Power | 550W | 1300W |

| Voltage | 220v,50Hz or 110V,60Hz | |

| Bag Width | 3-15cm | 10-20cm |

| Bag length | 1-15cm (adjustable) | 0-28cm or 0-39cm (adjustable) |

| Packing speed | 30-50 bags/min (Different material packaging weight at different speeds) | |

| Machine Weight | 60g | 90g |

| Machine size | 42*50*145CM | 90*66*180CM |

What are the advantages of Pouch Packing Machine?

The bag packaging machine has become a commonly used packaging equipment in various industries with its high efficiency, automation, versatility, flexibility and precise metering, providing a reliable solution for product packaging. The following are some of the main features of the bag packaging machine:

Automatic Operation: Pouch packing machines are designed for automated operation, reducing the need for manual intervention and increasing efficiency. They can perform tasks such as pouch forming, filling, sealing, cutting, and more, all in a continuous and synchronized manner.

Adjustable Pouch Sizes: Many pouch packing machines offer flexibility in handling different pouch sizes. They can be easily adjusted to accommodate various dimensions, allowing for packaging of products in different quantities or package formats.

Multiple Filling Options: Pouch packing machines can handle a wide range of products, including liquids, powders, granules, solids, and more. They often provide different filling mechanisms such as auger fillers, volumetric fillers, piston fillers, or pumps, allowing for precise and accurate product dosing.

Packaging Material Compatibility: Pouch packing machines are designed to work with various packaging materials, such as laminated films, plastic films, aluminum foil, and more. They can handle different thicknesses and types of films, ensuring compatibility with the specific packaging requirements of the product.

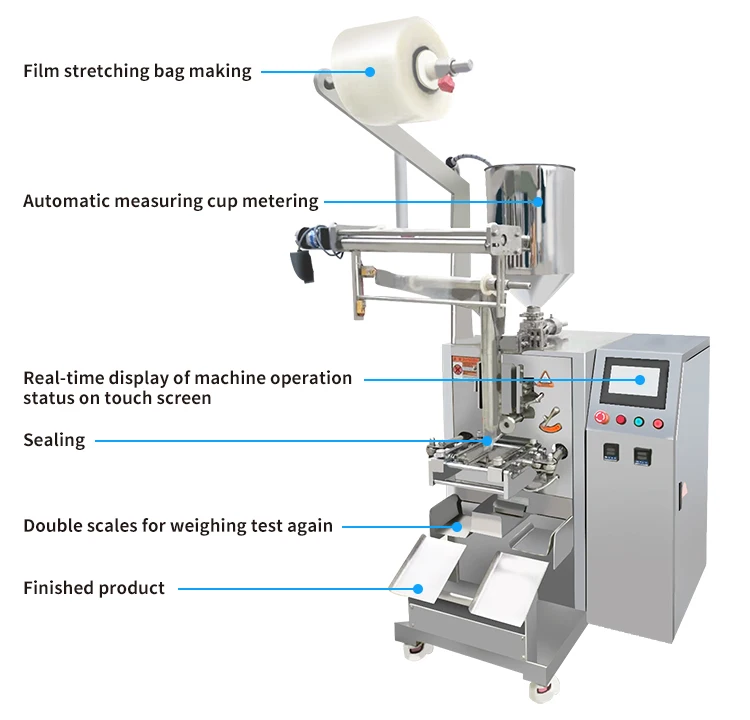

What are the structural components of Pouch Packing Machine?

Pouch Packing Machine usually consists of the following main parts, each of which plays a key role to ensure the smooth progress of the packaging process:

Feeding system: This part is responsible for conveying the product from the production line to the working area of the packaging machine. It can be a conveyor belt, a vibrating plate or other methods.

Bagging system: The bagging system includes steps such as unwinding, positioning, sealing and cutting of the roll film.

Metering and filling system: This part is used to accurately load the product into the bag, and can be metered or directly unloaded as needed.

Sealing system: The sealing system is responsible for sealing the bag filled with the product to ensure that the bag is sealed and maintain the freshness and quality of the product.

Cutting system: The cutting system is used to cut the sealed bag into individual packaging bags for subsequent packaging and use.

Control system: The control system is responsible for the operation and monitoring of the entire packaging machine to ensure the coordination and stability of each part.

Customer case

| Application scenario | Packaging product | Packaging volume | Packaging speed | Packaging bag size (width x length) | Packaging bag material |

| Food industry - Snack packaging | Mixed nuts | 50 g/bag | 40 bags/minute | 120mm x 180mm | Composite film (PET/AL/PE) |

| Daily chemical industry - laundry detergent sample packaging | Laundry detergent | 20 ml/bag | 60 bags/minute | 80mm x 120mm | PE |

| Pharmaceutical industry - Granular drug packaging | Cold granules | 10 g/bag | 30 bags/minute | 100mm x 150mm | Medicinal composite film (PET/PE) |

Pouch Packing Machine Price

Dahan Packaging Machine has many years of industry experience and technical accumulation. We are committed to providing customers with high-quality and efficient bag packaging machine solutions to meet the packaging needs of different industries. Our bag packaging machines use advanced technology and quality control standards to ensure that the equipment is stable and reliable, easy to operate, and has excellent packaging effects. The price is generally $495.00-$12,000.00. In addition to standard models, we can also customize solutions according to customers' specific requirements to ensure that the equipment and products are perfectly matched. You are welcome to contact us to learn more about our bag packaging machine product line and price details. We look forward to working with you to develop together and create a better future!

Pouch Packing Machine Manufacturer

Dahan Pouch Packing Machine Manufacturer is a leading provider of advanced packaging solutions, specializing in the design and production of high-quality pouch packing machines. With years of expertise, the company offers innovative, reliable, and efficient machines tailored to meet diverse industry needs, including food, pharmaceuticals, and cosmetics. Their state-of-the-art technology ensures precise packaging, extended shelf life, and reduced waste. Committed to customer satisfaction, Dahan provides comprehensive support, from installation to maintenance, ensuring seamless operations. Trusted globally, Dahan continues to set industry standards with its cutting-edge pouch packing solutions.

![[field:title/]](/uploads/231227/1-23122F9213WZ.png)