What is a vertical packaging machine?

Vertical packaging machine, also known as a vertical form-fill-seal (VFFS) machine, is a type of packaging equipment used to form, fill, and seal flexible packaging bags in a vertical orientation. It is commonly used in the food, pharmaceutical, cosmetic, and other industries for packaging various products such as snacks, powders, granules, liquids, and more.

Functions of vertical packaging machine

The vertical packaging machine, also known as a vertical form-fill-seal (VFFS) machine, performs several key functions in the packaging process. Here are the main functions of a vertical packaging machine:

1.Bag Forming: The machine forms a continuous tube from a roll of packaging film. It creates the shape and size of the bag according to the product requirements.

2.Product Filling: The machine dispenses the product into the formed bag. Depending on the type of product, the filling mechanism can be volumetric, auger-based, weigher-based, or liquid pump-based.

3.Sealing: The vertical packaging machine seals the bag to ensure product containment and freshness. There are typically multiple sealing stations for different types of seals, such as heat sealing, ultrasonic sealing, or impulse sealing.

4.Bag Discharge: The finished bags are discharged from the machine onto a conveyor belt or packaging line for further processing, such as labeling, cartoning, or palletizing.

Vertical Packaging Machine Video

Application of vertical packaging machine

Vertical packaging machines are versatile packaging equipment with a wide range of applications, and are commonly found in food, medicine, chemicals, agriculture and other industries. The following are some of the application areas of vertical packaging machines:

Food industry

Snacks: Packaging chips, nuts, popcorn, and other snack foods.

Confectionery: Packaging candies, chocolates, and gum.

Bakery Products: Packaging bread, cookies, pastries, and cakes.

Frozen Foods: Packaging frozen vegetables, fruits, and ready-to-eat meals.

Dried Foods: Packaging pasta, rice, beans, and other dried goods.

Fresh Produce: Packaging fruits, vegetables, and salads.

Pharmaceutical industry

Powders: Packaging medicinal powders and supplements.

Tablets and Capsules: Packaging pills and capsules in blister packs or sachets.

Herbal Products: Packaging herbal teas, supplements, and medicinal herbs.

Cosmetics and Personal Care

Powders: Packaging face powders, blush, and other cosmetic powders.

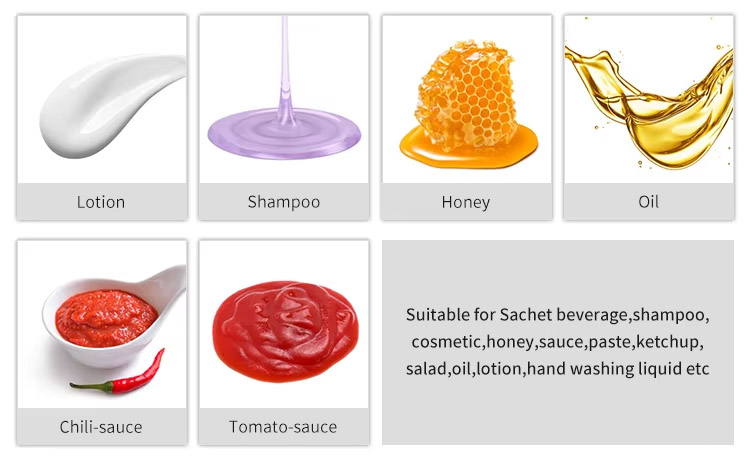

Creams and Lotions: Packaging small sachets of creams, lotions, and gels.

Soaps and Bath Products: Packaging soap bars, bath salts, and other bath products.

Chemical Industry

Detergents and Cleaners: Packaging powdered or liquid detergents, cleaning agents, and disinfectants.

Fertilizers and Pesticides: Packaging small quantities of fertilizers, pesticides, and other agricultural chemicals.

Pet Food Industry

Dry Pet Food: Packaging kibble and dry pet food

Treats: Packaging pet treats and snacks.

How does a vertical packaging machine work?

The operation of a vertical packaging machine involves the following steps:

Film Unwinding: The packaging machine unwinds a roll of packaging material, typically a flexible plastic film, from a reel.

Forming: The film is fed through a series of rollers and guides to create a tube or a vertical "V" shape.

Product Filling: The product being packaged is fed into the formed tube through a filling system. This can be achieved by gravity, auger fillers, volumetric fillers, or other methods, depending on the product's nature and characteristics.

Sealing: The vertical packaging machine seals the bag or pouch by applying heat or pressure to the film. This can be done by vertical heat sealers, ultrasonic sealers, or other sealing mechanisms.

Cutting: After sealing, the packaging machine cuts the film to separate the filled bag or pouch from the continuous tube.

What are the advantages of vertical packaging machines?

Vertical packaging machines offer several advantages, including:

Efficiency: They can achieve high packaging speeds, allowing for increased production rates and improved efficiency.

Versatility: These machines can handle a wide range of products and bag sizes, offering flexibility in packaging options.

Packaging Integrity: The vertical orientation of the bags helps maintain the integrity of the product during transportation and storage.

Space-saving: Vertical packaging machines typically have a compact footprint, making them suitable for facilities with limited space.

Easy Integration: They can be easily integrated into existing production lines or used as standalone units.

Vertical packaging machine specifications

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

Vertical packaging machine structure

Vertical packaging machines are usually composed of multiple components and structures to achieve automated packaging functions. The following are common components of vertical packaging machines:

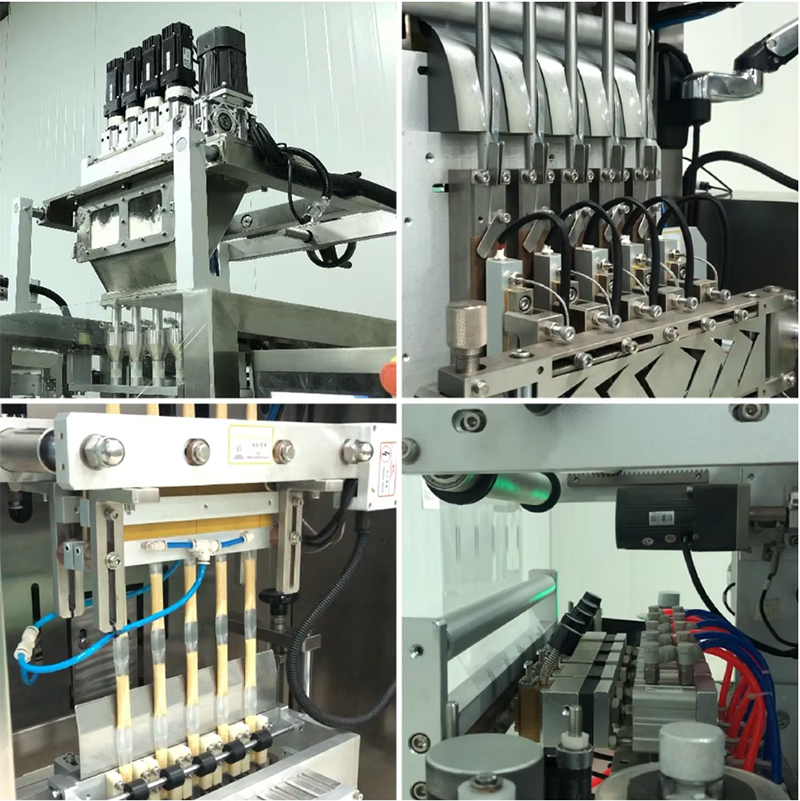

Feeding system: This system is used to transport raw materials to the working area of the packaging machine.

Measuring system: The measuring system is used to accurately weigh and measure raw materials to ensure that the weight of the product in each bag is accurate.

Bag forming system: This system is responsible for converting the printed packaging film or packaging paper into the required bag shape.

Filling system: The filling system fills the weighed product powder or granules into the bag.

Sealing system: The sealing system is used to seal the bag to prevent product leakage or external contamination. Common sealing methods include heat sealing, cold sealing and compression sealing.

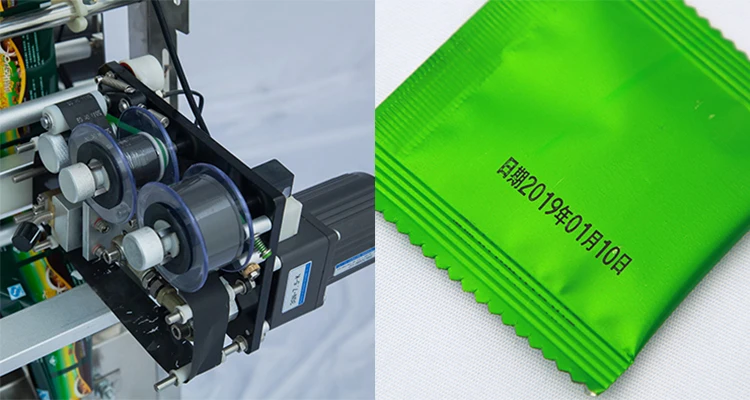

PLC control system: The control system is the brain of the entire packaging machine, responsible for monitoring and adjusting the operating status of the packaging machine to ensure that the various components work in coordination.

Options available

Vertical packaging machines, also known as vertical form-fill-seal (VFFS) machines, offer various options and features to meet specific packaging requirements. Here are some common options available for vertical packaging machines:

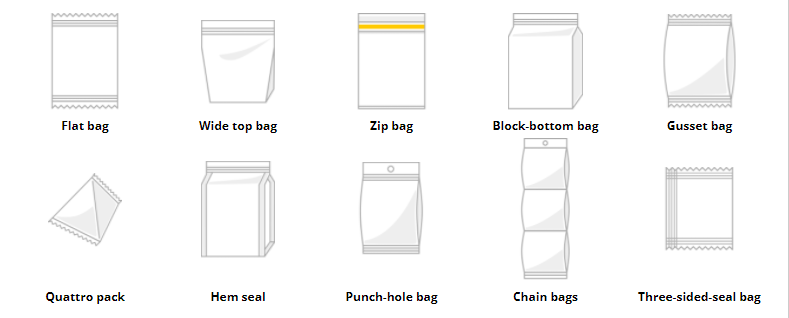

Bag Styles: Vertical packaging machines can produce different bag styles, including pillow bags, gusseted bags, quad seal bags, flat bottom bags, and more. The bag style is determined by the shape of the forming tube and the sealing mechanisms.

Packaging Film Options: These machines can handle various types of packaging films, such as polyethylene (PE), polypropylene (PP), laminated films, and barrier films. The choice of film depends on the product characteristics, shelf life requirements, and packaging aesthetics.

Filling Systems: Vertical packaging machines can be equipped with different filling systems based on the product being packaged. Common filling systems include volumetric fillers, auger fillers, weighers, liquid pumps, and piston fillers. The selection depends on the product's consistency, flow characteristics, and required accuracy.

Sealing Mechanisms: There are different sealing options available, including heat sealing, ultrasonic sealing, impulse sealing, or a combination of these methods. The choice depends on the packaging film material, product characteristics, and desired seal strength.

Integrated Systems: Vertical packaging machines can be integrated with other equipment, such as checkweighers, metal detectors, labeling systems, and cartoners, to create a complete packaging line.

Customer case

The Food Co., Ltd. is a food company specializing in the production of healthy snacks. As market demand grew, they quickly realized the need to improve production efficiency and packaging quality. To meet this demand, they decided to introduce an advanced vertical packaging machine. First of all, the high-speed packaging function of the packaging machine greatly improves production efficiency and effectively improves production capacity. Secondly, the precise measurement and automation functions of the vertical packaging machine ensure the consistency and quality stability of product packaging. Through the use of vertical packaging machines, Nansi Food has successfully increased product packaging efficiency by 30%, while reducing labor costs and packaging waste rates. This not only allows them to maintain a leading position in market competition, but also lays a solid foundation for future development.

Vertical Packaging Machine Manufacturers

Dahan vertical packaging machine manufacturer, we pay attention to customer needs, and can customize packaging machines according to customers' specific requirements to meet the packaging needs of different products. Our vertical packaging machines are widely used in packaging equipment in industries such as food, medicine, cosmetics, daily chemical products, agriculture and industrial products. As a professional vertical packaging machine manufacturer, we are committed to providing customers with high-quality and efficient packaging solutions. Our vertical packaging machines adopt advanced technology and design, with a variety of functional modules. Our team has rich experience and expertise, and can provide customers with a full range of pre-sales consultation, in-sales support and after-sales services. We are committed to working with our customers to achieve success and development together. Choosing us as your vertical packaging machine partner, you will get reliable packaging solutions to help your business achieve greater success.

![[field:title/]](/uploads/231227/1-23122F9192Y20.png)