What is an automatic rice packing machine?

Automatic rice packing machine is a specialized machine used for efficiently packaging rice into bags or containers. It is designed to automate the process of weighing, filling, and sealing rice bags, reducing manual labor and increasing packaging speed and accuracy.

Automatic rice packing machines vary in size and capacity, depending on the production requirements and packaging specifications. They are widely used in rice mills, food processing plants, and packaging facilities to streamline the rice packaging process, improve efficiency, and ensure consistent packaging quality.

Various types of automatic rice packing machine for sale

There are various types of automatic rice packing machines available, each with its own unique features and functionalities. Here are some common types:

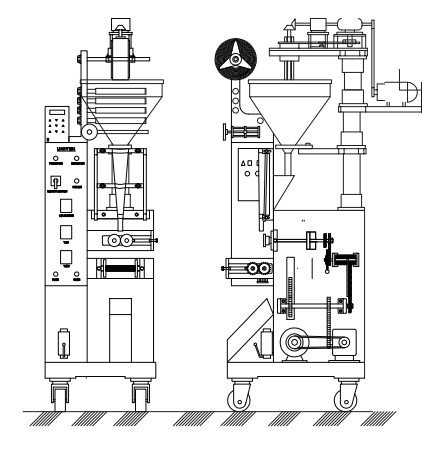

Vertical automatic rice packing machine: A vertical automatic rice packing machine, also known as a vertical form-fill-seal (VFFS) machine, is specifically designed to package rice efficiently and accurately.

Multi-head weighing and packing machine: Multihead weigher packing machines utilize a multihead weighing system to accurately measure and dispense the desired weight of rice into individual bags or containers. These machines are known for their high accuracy and consistency in rice packaging.

5-50kg rice packaging machine: 5-50kg rice packaging machine is designed specifically for packaging rice in larger quantities, ranging from 5 kilograms to 50 kilograms per bag. These machines are commonly used in rice mills, rice processing plants, and bulk packaging facilities.

What are the applications of automatic rice packaging machines?

The fully automatic rice packaging machine has important applications in all aspects of rice production, packaging and sales, and is suitable for packaging rice of various specifications and varieties. The following are some of the main application scenarios of the fully automatic rice packaging machine:

Rice Mills: Automatic rice packing machines are commonly used in rice mills to efficiently and accurately package different varieties of rice. They can handle various packaging sizes, such as 1kg, 5kg, 10kg, 25kg, or even larger quantities, depending on the specific requirements of the customers.

Food Processing Plants: Rice packing machines are also employed in food processing plants that produce packaged rice products, such as ready-to-eat meals, instant rice mixes, or rice-based snacks. These machines ensure consistent packaging and labeling of the products, maintaining their quality and freshness.

Automatic rice packing machines are widely used across the rice industry and related sectors to streamline the packaging process, improve efficiency, ensure accurate measurements, and maintain product quality and consistency.

Customer use site

What are the advantages of fully automatic rice packaging machine?

The fully automatic rice packaging machine is an important tool for the food industry to improve packaging production level and market competitiveness. It uses its own advantages to become an indispensable and important equipment in the rice processing industry. These advantages mainly include:

Each execution unit includes control and safety devices to enable the equipment to operate automatically and continuously.

Equipped with a sophisticated weighing system to accurately measure the weight of rice.

With multiple functions, it can meet different packaging needs.

Remote monitoring, data recording and production statistical analysis can be realized to improve production management efficiency.

Low packaging material loss and high quality of the sealing part improve product specifications.

Different feed hoppers, suitable for solids, liquids, concentrates, powders, etc.

Automatic rice packing machine specifications

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

Customer case

| Packaging Case | Packaging products | Customer feedback |

| A large grain and oil group, which owns several large grain processing plants in China, mainly produces and sells various brands of rice. |

1. The main packaging materials are refined rice of different varieties, including long-grain rice, round-grain rice, fragrant rice, etc. 2. The packaging specifications range from 1 kg to 25 kg, using plastic woven bags and kraft paper bags. |

After the introduction of the fully automatic rice packaging production line, production efficiency has been significantly improved, with daily output increasing by more than 30%; the automated packaging process has greatly reduced labor costs, reducing labor input by about 20%; packaging accuracy has been significantly improved, with the weight error of each bag of rice controlled within a very small range, reducing material loss. |

| A small or medium-sized rice mill located in a rice-producing area, mainly produces and sells local high-quality rice. |

1. The main packaging material is high-quality local rice, including organic rice, selenium-rich rice, etc. 2. The packaging specifications are mainly 5 kg and 10 kg, using vacuum packaging bags and pre-made bags. |

After using the fully automatic vacuum packaging machine, the rice mill successfully opened up the high-end market and doubled its product sales; vacuum packaging effectively extended the shelf life of the product and ensured the quality of the product; pre-made bag packaging improved the appearance of the product and attracted more consumers; the automated packaging process improved production efficiency and reduced labor intensity. |

| An agricultural product cooperative, which is composed of local farmers and mainly produces and sells various grains and agricultural products. |

1. The main packaging materials are various grains, including millet, beans, grain mixtures, etc. 2. The packaging specifications are mainly 1 kg and 2 kg, using self-sealing bags. |

The cooperative has achieved standardized packaging of agricultural products and increased product added value by using fully automatic grain packaging machines; standardized packaging specifications and appearance have facilitated product sales and transportation; the automated packaging process has reduced the labor burden of farmers and improved production efficiency; and standardized packaging has also increased farmers' income. |

How to choosing an automatic rice packing machine?

We can choose the appropriate packaging machine according to the packaging requirements of the product, the production volume of the product and our own situation, understand the product features and technical parameters in detail, and make the most appropriate choice.

Packaging Requirements: Determine the desired packaging formats, bag sizes, and speeds to meet specific needs.

Capacity and Throughput: Consider the machine's capacity to meet current and future production demands.

Materials: Ensure that the machine is compatible with the types of packaging materials and rice to be handled.

Sanitation and Hygiene: Evaluate the machine's design and features to ensure easy cleaning and minimize contamination risks.

Automation Level: Determine the desired level of automation, including automatic bag forming, filling, seal

Do you know the price for the automatic rice packing machine?

The price of an automatic rice packing machine can vary depending on several factors, including the machine's specifications, features, brand, and the supplier or manufacturer. Additionally, market conditions and geographical location can also influence the price.

To get an accurate price for an automatic rice packing machine, it is recommended to reach out to suppliers or manufacturers directly. They can provide you with detailed information about the machine's pricing based on your specific requirements and any additional customization or features you may need.

Why choose us as your top automatic rice packing machine supplier?

Xinxiang Dahan automatic rice packing machine is a manufacturer specializing in the production of automated rice packaging machines. Their products are known for their efficient and precise packaging of rice grains and are suitable for the packaging needs of all types of rice grains. Xinxiang Dahan Manufacturer provides machines of various specifications and models, which can meet different needs from small packaging to large packaging, and provides high-quality after-sales service.