What is a powder packaging machine?

Powder packaging machine is a type of equipment used for packaging powdered products into bags, pouches, or other containers. It is commonly used in industries such as food, pharmaceuticals, chemicals, and cosmetics. The machine automates the process of weighing, filling, sealing, and labeling the powder products, increasing efficiency and accuracy in packaging operations.

Powder packaging machines can be versatile and customizable to suit specific packaging requirements, including different bag sizes, packaging materials, and production capacities. The choice of machine will depend on factors such as the type of powder, desired packaging format, production volume, and automation level required.

Various types of powder packaging machine for sale

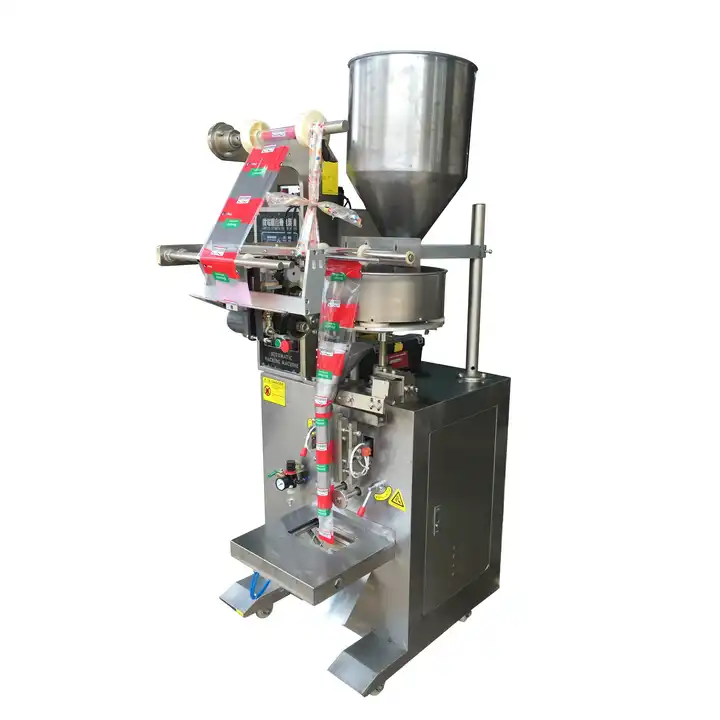

Powder Packaging Machine has vertical type and spiral type, and you can choose the corresponding equipment according to the properties and needs of the powder product.

| Vertical Powder Packaging Machine | Screw Conveyor Powder Packaging Machine | |

| Operation | Typically a form-fill-seal machine, it forms a bag from a roll of film, fills the bag with the powdered product, and then seals the bag. | use a screw conveyor to transport powdered products from a hopper to the packaging area. |

| Design | designed to package products vertically, making them suitable for creating pillow bags, gusseted bags, and other vertical bag styles. | suitable for filling and packaging powdered products with controlled dosing requirements. |

| Application | Vertical powder packaging machines can be used for a wide range of powder packaging applications. | suitable for filling and packaging powdered products with controlled dosing requirements. |

In addition, the Powder Packaging Machine has an automatic metering system (to ensure the same amount of powder in each packaging bag), an aeration function (to protect the freshness of the powder and extend the shelf life), a printing function (production date, batch number and other information can be printed on the packaging bag), a multi-function operation panel (to facilitate operation and monitoring of the production process), a dustproof system (to protect the internal components of the powder packaging machine and extend the service life of the equipment) and other functions, which can be selected according to the packaging needs of different powder products and the requirements of the production environment.

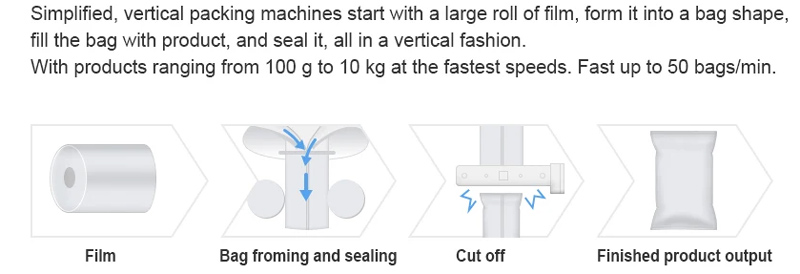

How does a powder packaging machine work?

First, the powder enters the storage bin of the packaging machine through the unloading system. Then, the metering system will automatically measure based on the set formula and quantity to ensure that the amount of powder in each packaging bag is exactly the same. Next, the filling system will fill the measured powder into the packaging bag and vibrate or compact it as needed to ensure uniform filling and compactness of the powder. Finally, the sealing system will perform heat sealing, cold sealing or pressure sealing on the packaging bag to ensure that it is completely sealed.

What powder can the machine package?

Powder packaging machines can be used to package various powder products, covering multiple industries. Here are some common types of powders that can be packaged using powder packaging machines:

Food powder: including powdered foods such as flour, sugar, salt, spices, coffee, tea, milk powder, cocoa powder, baking mix, protein powder and nutritional supplements.

Pharmaceutical powders: including powdered drugs, vitamins, herbal supplements, powdered antibiotics and other pharmaceutical powders.

Chemical powders: This category includes a variety of powdered chemicals used in different industries such as fertilizers, pesticides, detergents, pigments, dyes and other powdered chemical compounds.

Industrial powders: This category includes various powders used in industrial applications, such as powdered metals, ceramics, construction materials and additives in production processes.

Nutraceutical powders: These are powders used in the manufacture of dietary supplements, functional foods and nutraceuticals, including vitamins, minerals, herbal extracts and other nutritional powders.

Powder Packaging Machine Video

What are the advantages of powder packaging machine?

The powder packaging machine has the characteristics of high-speed packaging, strong adaptability, and precise control, providing an efficient, accurate and reliable solution for the packaging of powder products. Its characteristics include but are not limited to the following aspects.

Improve production efficiency: The powder packaging machine can realize automated powder metering, packaging and sealing, which greatly improves production efficiency. Compared with manual packaging, the powder packaging machine can complete the packaging task at a faster speed, saving time and labor costs.

Accurate measurement and packaging: Through advanced measurement system and precise control, precise measurement and accurate packaging of powder can be achieved. This ensures a consistent amount of powder in each bag or container, ensuring product quality and specification stability.

Reduce packaging costs: It can reduce the risk of manual operations and packaging errors, improve packaging efficiency and consistency, thereby reducing packaging costs.

Maintain hygiene and safety: Cleaning and sanitation facilities, such as dust collection systems and easy-to-clean materials, are usually equipped to maintain the hygiene of the production environment and the safety of operators.

Improve packaging quality: The powder packaging machine can achieve a precise packaging process, avoiding problems such as missed filling, overfilling or uneven filling of packaging bags or containers, and improves packaging quality and the appearance appeal of the product.

Powder packaging machine specifications

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

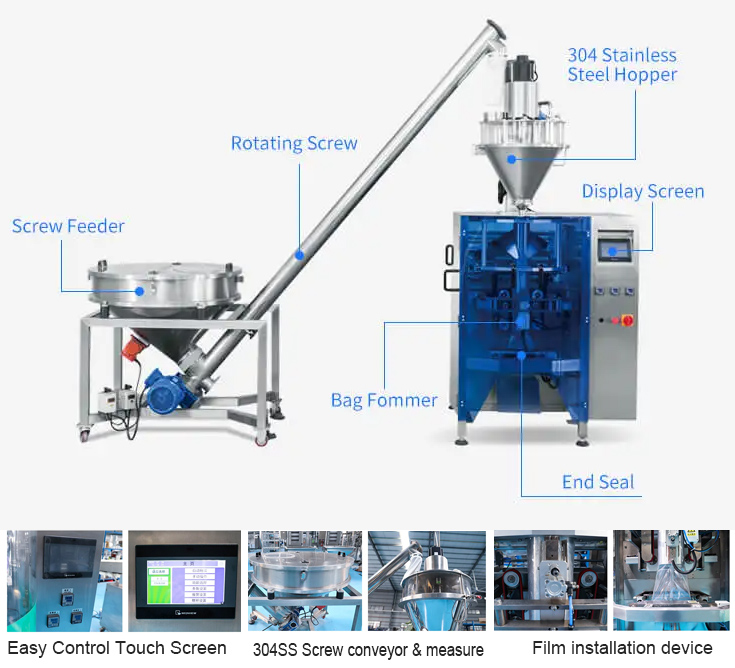

Structure of powder packaging machine

The structure of a powder packaging machine can vary depending on the specific model and manufacturer. However, most powder packaging machines generally consist of the following key components:

Hopper: This is a container that holds the powdered material to be packaged. It usually has a large capacity and is equipped with a mechanism to control the flow of the powder into the packaging system.

Auger Filler: An auger filler is a screw-like mechanism that accurately measures and dispenses the desired amount of powder into the packaging container. The auger rotates and moves the powder forward, filling the packaging bags or containers.

Packaging Material Supply: The machine is equipped with a system to supply the packaging material, such as rolls of film or pre-formed bags. The packaging material is pulled and formed into the desired shape to hold the powder.

Sealing Mechanism: Once the powder is dispensed into the packaging container, the machine seals the packaging material to create a secure and airtight seal. Different sealing methods can be used, such as heat sealing, ultrasonic sealing, or mechanical sealing, depending on the machine design.

Control Panel: The machine features a control panel that allows the operator to set and adjust various parameters, such as filling quantity, bag length, sealing temperature, and speed. It also includes an interface to monitor and control the machine's operation.

Conveyor System: A conveyor system is often integrated into the machine to transport the filled and sealed packages to the next stage of the packaging process, such as labeling or cartoning.

Powder Packaging Machine Application Case

| Application scenario | Packing volume | Packing speed | Packing size | Packing bag material | Solution |

| A food additive manufacturer in the Philippines needs to package vitamin C powder, which requires dust-free, moisture-proof, and high-precision measurement. | 500g/bag | 40-45 bags/minute | 200mm (length) × 150mm (width) | Aluminum-plastic composite film (moisture-proof and light-proof) | Fully automatic powder packaging machine, equipped with a spiral metering system, accuracy ±0.5%, closed design to reduce dust flying, ensuring that the hygiene standards meet food grade requirements. |

| A German chemical company needs to package calcium carbonate powder, requiring high efficiency and wear resistance. | 25kg/bag | 60-70 bags/minute | 800mm (length) × 500mm (width) | PP woven bag (lined with PE film, leak-proof powder) | Use valve-type large bag powder packaging machine, equipped with pneumatic bag clamping device, automatic weighing and sewing bag, can process more than 500kg per hour, greatly improving bagging efficiency. |

| A pharmaceutical company in the United States needs to repack antibiotic powder, requiring a sterile environment and high-precision filling. | 10g/bag | 60-70 bags/minute | 100mm (length) × 80mm (width) | Medical grade composite film (air permeability controllable, in line with GMP standards) | Adopt servo-driven powder packaging machine, accuracy ±0.1%, with aseptic filling system to ensure that the powder is free of contamination, suitable for small-dose high-value products. |

Things you need to consider when buying a powder packaging machine

When purchasing a powder packaging machine, the following points are worth considering:

1. Packaging requirements: First, you need to clarify your own packaging requirements, including powder type, packaging specifications, packaging speed requirements, etc.

2. Powder characteristics: Different powders have different characteristics such as fluidity, density and viscosity, which will affect the selection and performance of packaging machines.

3. Packaging containers and forms: Determine the packaging containers and packaging forms to be used, such as bags, cans, bottles, etc. Different packaging forms may require different filling devices, sealing devices, label attachment devices, etc.

4. Degree of automation: Consider the degree of automation of the packaging production line. Some powder packaging machines can be linked with other equipment to realize automated material transportation, packaging and sealing processes.

Why choose us as your top powder packaging machine supplier?

Xinxiang Dahan powder packaging machine has the advantages of high precision, high efficiency, flexibility and stability. It adopts advanced metering control technology to achieve precise powder filling and packaging, improving packaging accuracy and consistency; high-speed packaging capabilities can quickly complete the filling, sealing and packaging processes and improve production efficiency; the flexible design can be customized according to different packaging Adjustment and customization according to requirements and product characteristics; stable and reliable mechanical structure and control system ensure stable operation and long-term reliability of the equipment; easy-to-operate interface and control system enable operators to easily master the operation and adjustment of the machine; high-quality manufacturing Workmanship guarantees product reliability and durability. In short, the Xinxiang Dahan powder packaging machine is a reliable and efficient packaging equipment that is suitable for the packaging needs of various powder products.

Want to know the powder packaging machine price?

The price of a powder packaging machine can vary depending on several factors, including the machine's specifications, capabilities, brand, and the supplier or manufacturer. Different machines may have different price ranges based on their features and quality.

Generally, powder packaging machines can range in price from a few thousand dollars to tens of thousands of dollars. More advanced and automated machines with higher production capacities and precision tend to be on the higher end of the price spectrum.