What is a combined weighing and packaging machine with a Z conveyor?

Combined weighing and packaging machine is a versatile packaging system that integrates weighing, conveying, and packaging functions into a single automated process. It is commonly used in various industries, including food, pharmaceuticals, and hardware, for efficiently packaging a wide range of products.

The combined weighing and packaging machine with a Z conveyor is a highly efficient and versatile system designed to automate the weighing and packaging of various products in a continuous and efficient manner. This integrated solution combines a weighing unit, a packaging machine, and a Z conveyor to streamline the packaging process, reduce manual labor, and improve overall productivity.

How does combined weighing and packaging machine with a Z conveyor work?

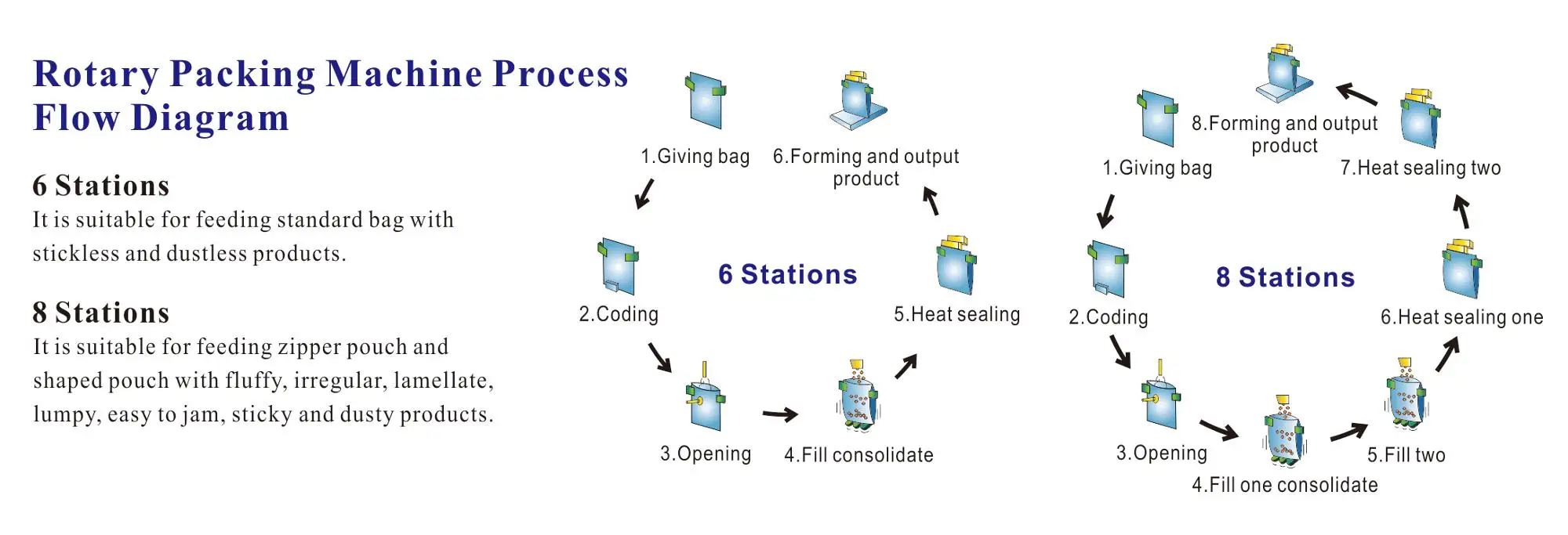

Product Feeding: The product to be packaged is fed into the machine's hopper or feeding system. The Z conveyor transports the product from the hopper to the weighing section.

Weighing: The machine is equipped with a weighing system that accurately measures the desired weight of the product. This can be achieved using load cells or other weighing mechanisms. The weighing system ensures precise and consistent product quantities for each package.

Dispensing: Once the desired weight is achieved, the Z conveyor transports the product to the packaging section. The product is dispensed into the packaging material, such as bags, pouches, or containers.

Packaging: The packaging material is formed, sealed, and cut to create individual packages. This can be done using various packaging techniques, such as vertical form-fill-seal (VFFS) or horizontal form-fill-seal (HFFS) methods.

Conveyor Movement: The Z conveyor moves the packaged products from the packaging section to the next stage, such as labeling, coding, or collection.

Features of combined weighing and packaging machine with a Z conveyor

Automation: The combined weighing and packaging machine eliminates the need for manual weighing and packaging, significantly reducing labor costs and increasing productivity.

Accuracy: The high-precision scales in the weighing unit ensure accurate and consistent product weights, minimizing product giveaway and improving product quality.

Speed: The continuous operation of the system, combined with the efficient product distribution mechanism, allows for fast and uninterrupted packaging of products.

Flexibility: The system can be customized to handle different product sizes, shapes, and packaging formats, making it highly versatile for various applications.

Space Optimization: The compact design of the combined machine and Z conveyor optimizes floor space utilization within production facilities.

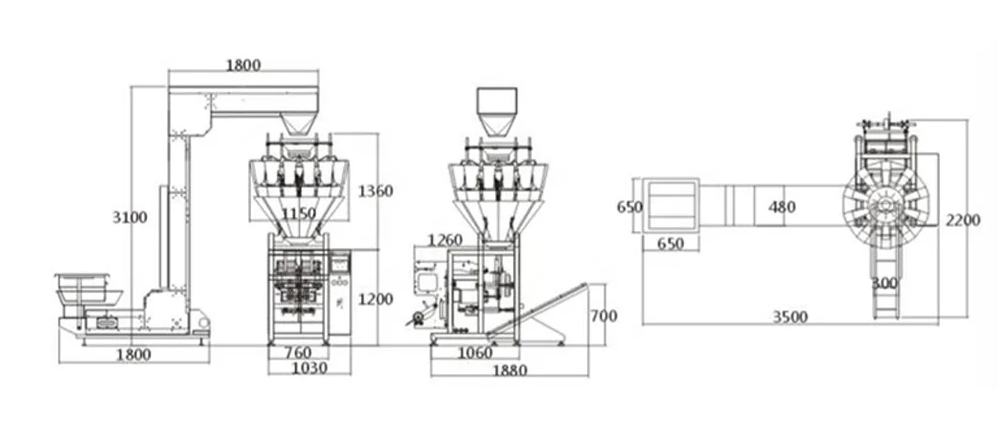

Combined weighing and packaging machine with a Z conveyor specifications

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

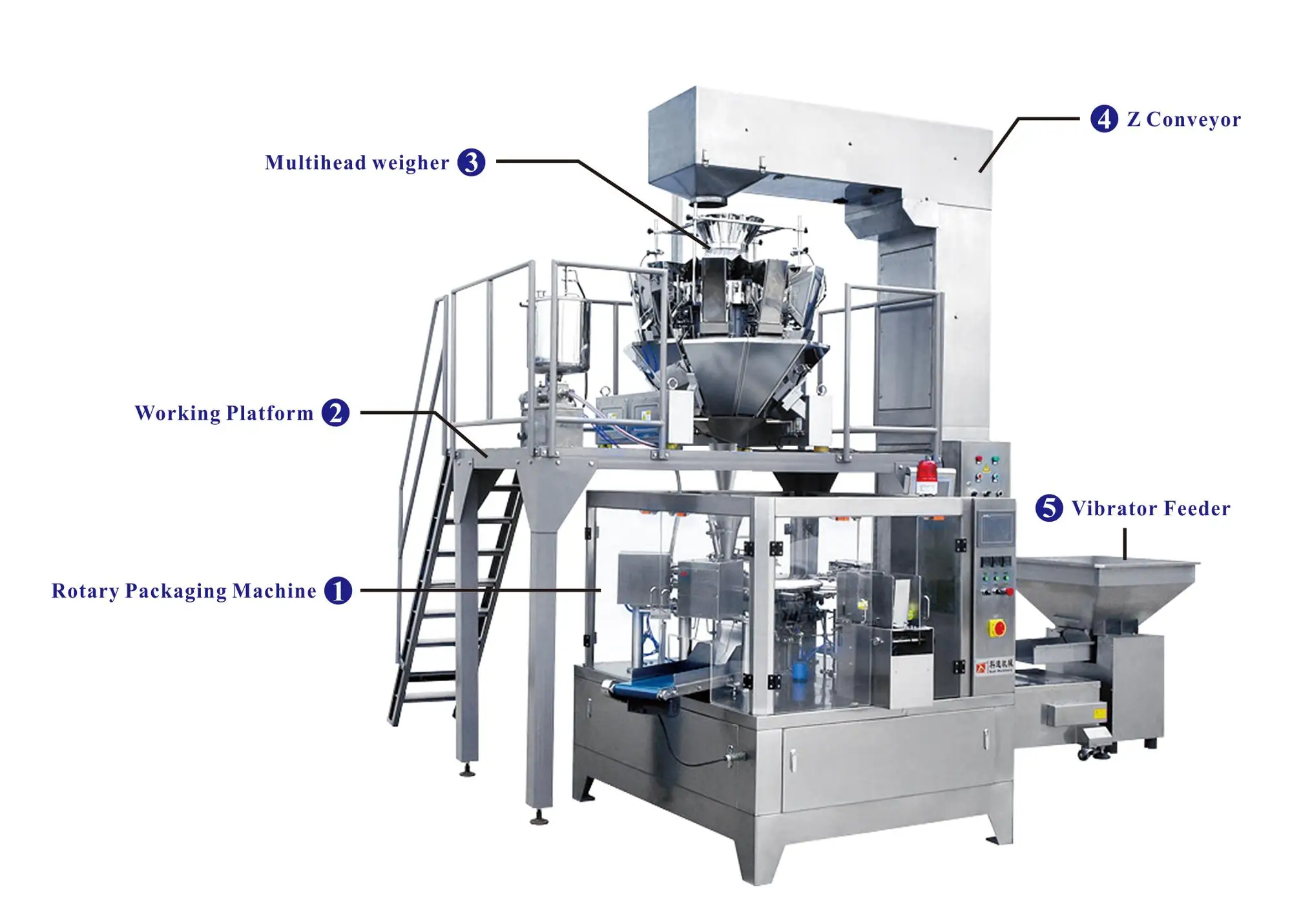

Structure of combined weighing and packaging machine with a Z conveyor

1. Weighing Unit:

* Equipped with high-precision scales to accurately weigh products according to predetermined target weights.

* Customizable to accommodate various product sizes and shapes.

* May incorporate multiple weighing heads for increased throughput.

2. Packaging Machine:

* Utilizes advanced packaging technology such as vertical form, fill, and seal (VFFS) or horizontal form, fill, and seal (HFFS) to create sealed packages.

* Typically capable of handling various packaging materials, including films, pouches, and bags.

* Can be equipped with additional features like coding and labeling systems.

3. Z Conveyor:

* The Z conveyor serves as the connecting element between the weighing unit and the packaging machine.

* Designed with a unique Z-shaped configuration to optimize product flow and minimize product damage during the transfer process.

What are the applications of combined weighing and packaging machine with a Z conveyor?

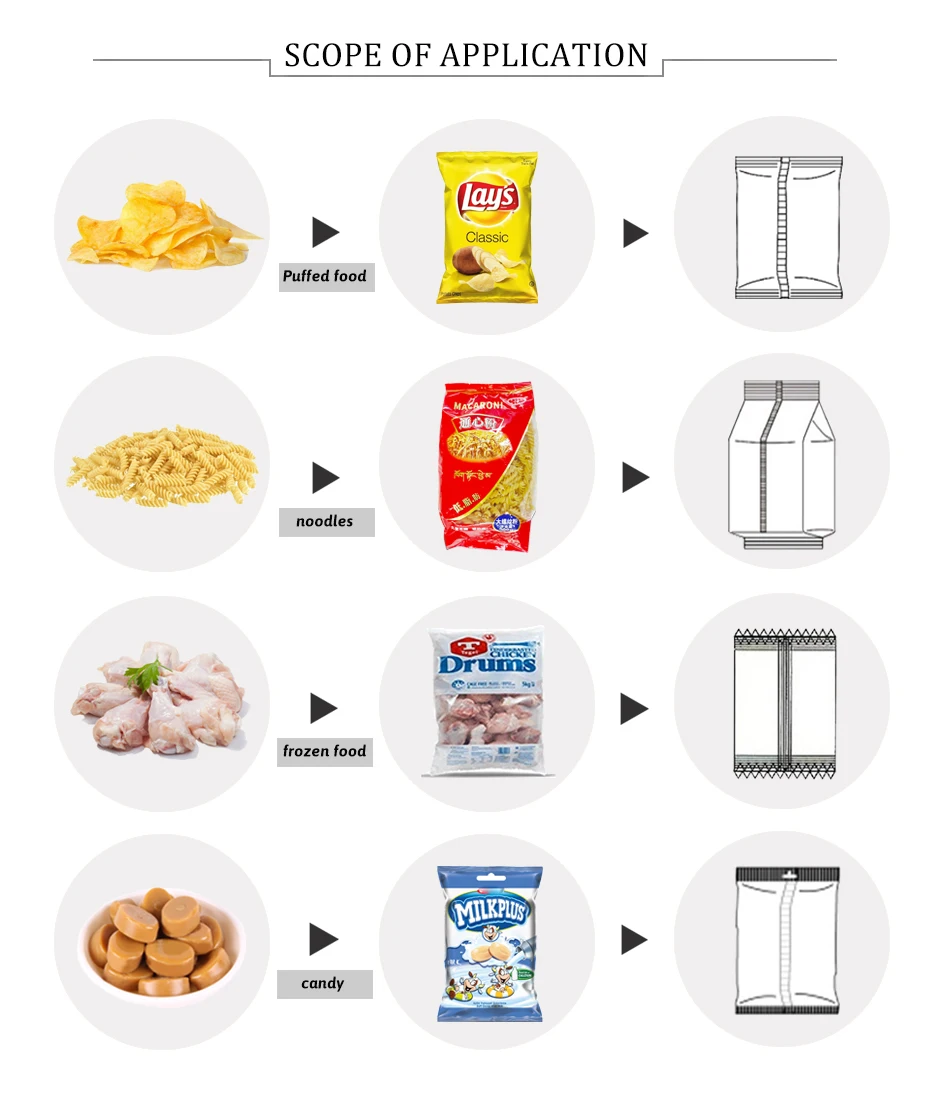

Food and Beverage Industry: For packaging snacks, confectionery, dry foods, and liquid products.

Pharmaceutical Industry: For dispensing and packaging tablets, capsules, and powders.

Cosmetics and Personal Care: For filling and packaging creams, lotions, and powders.

Industrial Products: For packaging small hardware, electronic components, and other industrial items.

E-commerce and Retail: For packaging and shipping products sold online or in retail stores.

Customer case

![[field:title/]](/uploads/240104/1-2401041H306220.png)