What is food packaging machine?

Food packaging machine, also known as a food packaging system or food packaging equipment, is a device or a set of devices used in the food industry to package various food products efficiently and hygienically. These machines automate the process of packaging food items, ensuring consistency, speed, and accuracy.

Food packaging machines are designed to handle different types of food products such as snacks, baked goods, dairy products, frozen foods, fresh produce, beverages, and more. They can package food items into various forms such as bags, pouches, trays, cartons, bottles, cans, or containers, depending on the specific requirements of the product.

What are the types of food packaging machine?

Food Packaging Machine has bag-making and filling type, vertical type, vacuum type, and combined type. You can choose the corresponding equipment according to the needs of different packaging products.

-

Form-Fill-Seal Machines

These machines form the packaging material into a bag or pouch, fill it with the food product, and then seal it. They can handle a wide range of products such as snacks, grains, powders, and liquids.

-

Vertical Form-Fill-Seal Machines

These machines form a bag from a roll of packaging film, fill it with the food product, and then seal it. They are commonly used for packaging items like powders, grains, and snacks.

-

Vacuum Packaging Machines

These machines remove air from the packaging to create a vacuum-sealed environment, which helps extend the shelf life of the food product. They are often used for perishable items like meat, cheese, and seafood.

-

Vertical Automatic Packaging Machine

These machines are typically used to package items such as snacks, candies, biscuits, granular or powdered ingredients, frozen foods, and more. Vertical design enables space-saving and high-speed packaging operations.

-

Combined Weighing And Packaging Machine With Screw Feeder

These machines are commonly used for packaging items like spices, flour, sugar, coffee, powdered beverages and other similar products. Screw feeders control the flow of material into the weighing system.

-

Combined Weighing And Packaging Machine With Z Conveyor

These machines are typically used to package items such as snacks, candies, biscuits, granular or powdered ingredients, frozen foods, and more. Vertical design enables space-saving and high-speed packaging operations.

How to choose a food packaging machine?

When choosing a Food Packaging Machine, you need to consider food type, packaging size, packaging volume, packaging speed, packaging bag material, etc.

Food type: For solid food (granules, blocks, flakes such as biscuits, nuts, candies, potato chips, frozen dumplings), you should choose vertical packaging machines, pillow packaging machines, and bag packaging machines; for powdered food (milk powder, starch, seasoning powder, coffee powder), you should choose powder packaging machines and spiral metering packaging machines; for liquid/sauce food (sauce, soy sauce, jam, honey, yogurt), you should choose liquid filling machines and sauce packaging machines; for frozen food (dumplings, seafood, pre-prepared dishes), you should choose vacuum packaging machines and heat shrink packaging machines.

Packaging size: small bags (50-150mm) use vertical packaging machines, such as candy, nuts, and seasonings; medium bags (150-500mm) use pillow packaging machines, such as biscuits, potato chips, and frozen foods; large bags (over 500mm) use bag-feeding packaging machines, such as rice, pet food, and industrial food.

Packing volume and packing speed: The packaging speed of food packaging machines is 20-400 bags/minute. The required packaging speed can be determined by your production volume and target output.

Packaging bag material: PE/PP composite film, aluminum foil film, kraft paper/degradable film, shrink film, etc. are available. The packaging forms include bags, pouches, bottles, cartons, etc. The corresponding material can be selected according to the characteristics of the food.

Live Video

Food packaging machine specifications

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

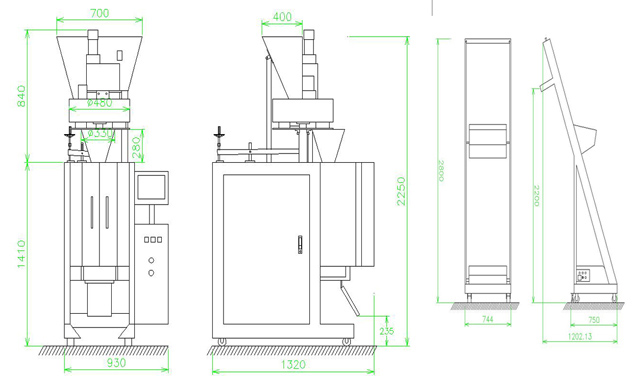

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

How does a food packaging machine work?

A food packaging machine automates the packaging process of food products. It typically involves feeding the products into the machine, accurately weighing or measuring them, handling the packaging material, filling it with the products, sealing it securely, and discharging the packaged products. The machine incorporates various mechanisms and sensors to ensure precise portioning, hygienic packaging, and efficient operation, ultimately improving productivity and maintaining product quality.

What are the advantages of food packaging machine?

Food Packaging Machine plays a vital role in the food processing and production industry. It is mainly used to automatically package food to improve production efficiency, ensure food safety, and optimize costs. The following are the main advantages of Food Packaging Machine

High-speed packaging: The food packaging machine can achieve a packaging speed of 200 packs per minute, far exceeding the efficiency of manual packaging, and can run 24 hours a day to meet the needs of large-scale production.

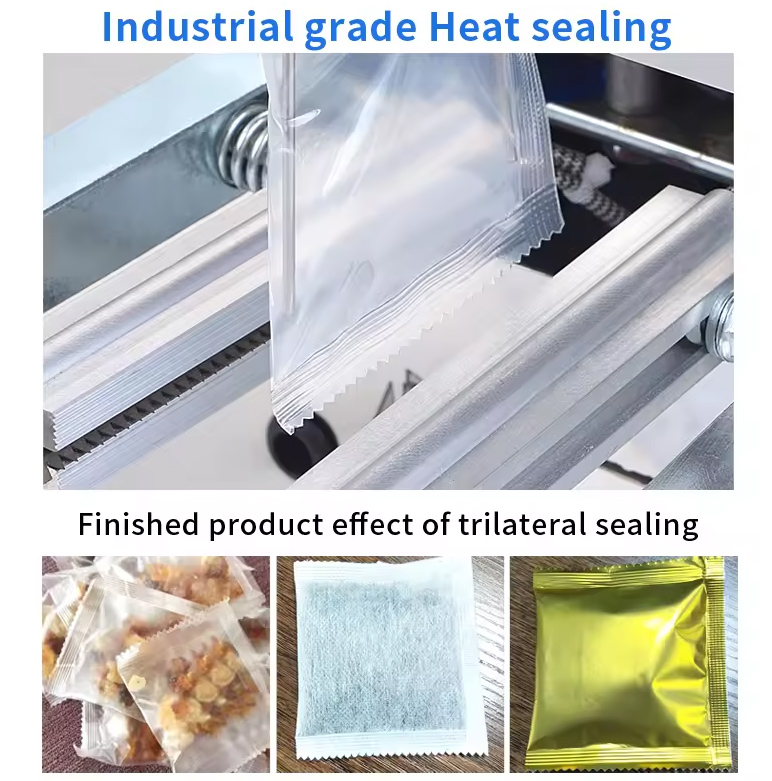

Ensure food safety and reduce pollution: The use of advanced heat sealing and vacuum packaging technology can effectively prevent food from moisture, oxidation and deterioration, and fully automated packaging can save costs and reduce the risk of contamination.

Improve packaging quality and consistency: The multi-head weighing system ensures that the weight of each bag of product is consistent, and the automated packaging ensures that the seal is flat and the label is aligned, which enhances the brand image.

Accurate measurement and weighing: The food packaging machine is equipped with a high-precision measurement and weighing system to ensure that the weight of each portion of food is accurate, meet product quality standards, and reduce resource waste.

Structure of food packaging machine

The structure of a food packaging machine can vary depending on its type, design, and the specific packaging requirements. However, here are some common components and structures found in food packaging machines:

1.Frame: The frame forms the structural support for the entire machine. It is usually made of sturdy materials such as stainless steel or aluminum to ensure stability and durability.

2.Weighing or Measuring System: Food packaging machines often have a weighing or measuring system to accurately portion the food products. This can include load cells, sensors, or volumetric measuring devices to achieve precise measurement.

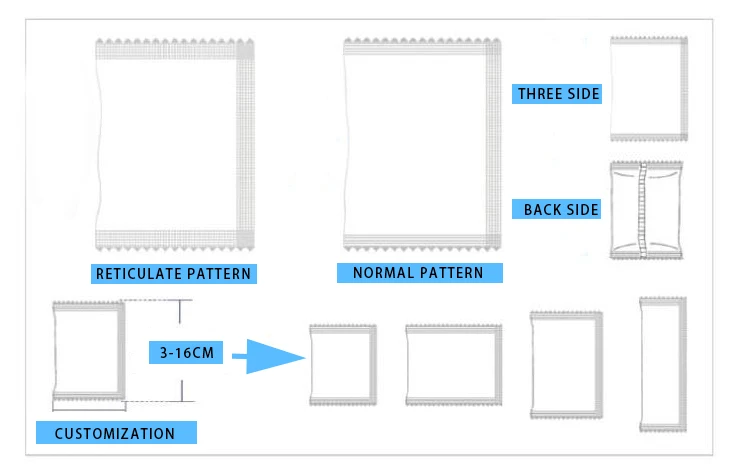

3.Packaging Material Handling: The packaging machine is designed to handle the packaging material, which can include pre-formed bags, rolls of film, or other packaging formats. It may include mechanisms for forming, cutting, and sealing the packaging material.

4.Filling Mechanism: The filling mechanism dispenses the measured or weighed food products into the packaging material. This can involve augers, screw feeders, vibratory trays, or piston fillers, depending on the characteristics of the food products.

What are the applications of food packaging machine?

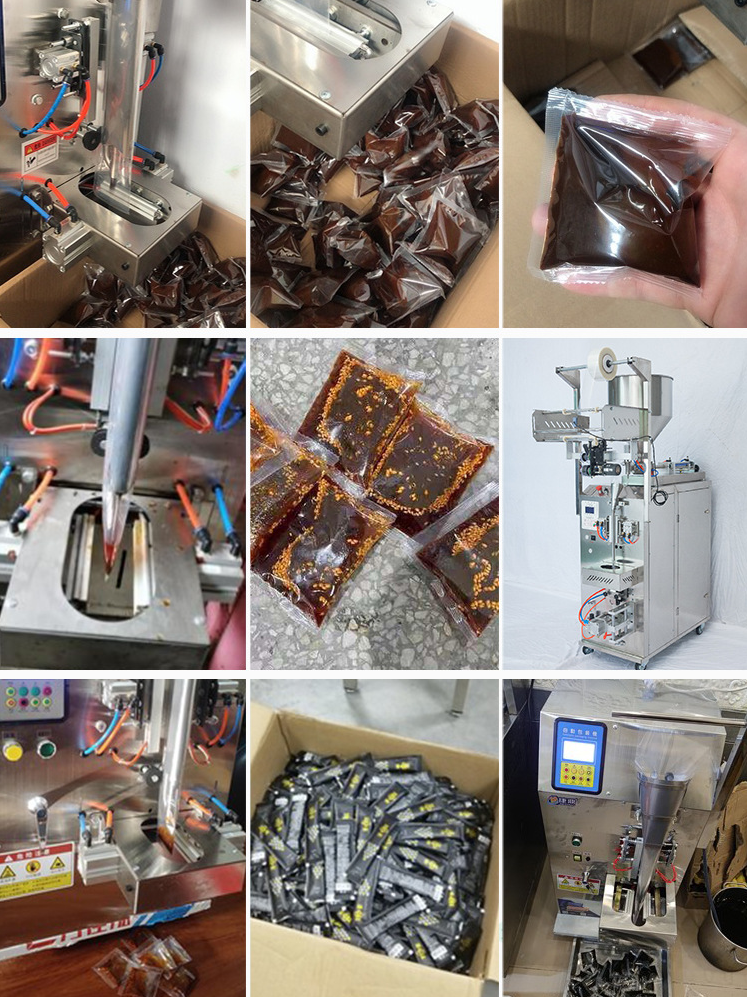

Food Packaging Machine is widely used in the food industry, covering the packaging needs of dry goods, liquids, powders, granules, frozen and fresh foods. In the packaging of dry goods, such as biscuits, potato chips, nuts, candies, etc., the packaging machine can effectively keep the products crisp and fresh. Liquid foods such as juice, milk, sauces, salad dressings, etc. can be packaged without leakage and with high efficiency through liquid packaging machines. Powdered foods such as coffee powder, flour, seasonings, protein powder, etc. can be accurately measured and packaged by powder packaging machines. Granular foods such as rice, beans, grains, seeds, etc. can be packaged efficiently and accurately by granule packaging machines. Frozen foods such as frozen meat, seafood, dumplings, ice cream, etc. can be packaged efficiently and accurately by packaging machines. Packaging machines can provide good sealing to prevent freezer burns for frozen foods such as frozen meat, seafood, dumplings, ice cream, etc. Fresh foods such as fruits, vegetables, meat, bread, etc. can be kept fresh and their shelf life extended by packaging machines. In summary, food packaging machines play an important role in improving packaging efficiency, ensuring food quality and extending shelf life.

Customer case

Food packaging machines are widely used in the food industry, which can significantly improve production efficiency, reduce labor costs, and ensure product quality. Through flexible configuration and precise control, video packaging machines can adapt to the packaging needs of different products and bring higher economic benefits to food companies.

| Customer Sase | Packaging Materials | Type of Packaging | Packaging Materials | Packing Quantity |

| Cookie company | Biscuit | Individual cookie packaging | Plastic film | Packaging 200 biscuits per minute |

| Quick frozen food company | Quick frozen dumplings | Bag | Plastic film and trays | Packing 1,000 packs of quick-frozen dumplings per hour |

| Coffee company | Coffee powder | Bag | Composite film bag | Packaging 500 grams of coffee powder per minute |

| Juice factory | Juice | filling | Liquid packaging bag | Packaging of 1,000 bags of juice per hour (200ml per bag) |

Food packaging machine case: The biscuit company needs to improve production efficiency and ensure packaging quality to meet the growing market demand. We provide a customized packaging machine solution for the biscuit company, realizing the automated packaging process, improving production efficiency and packaging consistency.

Frozen food company case: The frozen food company needs to improve packaging speed and accuracy to meet the growing order demand. We provide a set of efficient video packaging machine solutions for the frozen food company, which increases the packaging speed by 50%, improves accuracy, and greatly improves production efficiency.

Coffee company case: The coffee company needs to improve the automation of coffee packaging to ensure the freshness and quality of coffee. We provide a set of intelligent video packaging machine solutions for the coffee company, realizing the automated control of coffee packaging and monitoring of the packaging process.

Juice factory case: The juice factory needs to improve the production efficiency and hygiene standards of juice packaging to meet the growing market demand. We provided a set of efficient and hygienic video packaging machine solutions for the juice factory, which increased the packaging efficiency by 40% and ensured the hygiene standards.

Why is a food packing machine important?

A food packaging machine is important because it automates the packaging process, increasing efficiency and productivity. It ensures consistent and accurate portioning, maintains food safety and hygiene standards, extends shelf life, supports branding and marketing efforts, and helps in cost savings. Overall, it plays a vital role in streamlining the packaging process and delivering high-quality packaged food products to consumers.

Food Packaging Machine Price

Dahan Food Packaging Machine Price is $495.00-$15,800.00.

Functionality and Automation: Fully automatic equipment (such as flow packaging machines with touch screens) is more than 50% more expensive than semi-automatic or manual equipment.

Capacity requirements: The greater the processing volume per hour, the higher the price. For example, the price of equipment with a capacity of 200 tons/month is usually more than $20,000.

Material adaptability: Models that support a variety of packaging materials (such as plastics, paper, and composite materials) are more expensive. For example, a sealing machine compatible with hot/cold foods requires special design, and the price may increase by 30%.

Brand and certification: Brands that have passed ISO 9001 or GMP certification (such as FOSHAN UPPER MACHINERY) are usually more expensive than uncertified manufacturers.

Food packaging machine manufacturers

Xinxiang Dahan food packaging machine manufacturer is that it specializes in manufacturing high-quality and reliable food packaging machines. They have advanced technology and equipment and focus on product innovation and research and development to meet the changing needs of customers. They provide a full range of solutions, including various packaging types and packaging materials, while providing reliable after-sales service and technical support to provide customers with excellent packaging solutions.