What is a sachet filler & packaging machine?

Sachet filler and packaging machine is a specialized equipment designed to automatically fill and package various products into individual sachets or pouches. This type of machine is commonly used in industries such as food and beverage, pharmaceuticals, cosmetics, and household products. It offers efficient and precise packaging solutions, ensuring product integrity and convenience for consumers.

The sachet filler and packaging machine offers several advantages, including high-speed operation, accurate filling, and consistent packaging quality. It is suitable for packaging a wide range of products, including powders, granules, liquids, creams, and gels. This machine enhances productivity, reduces labor costs, and provides convenient and hygienic packaging for various consumer goods.

Different types of sachet filler & packaging machinee for sale

There are several types of sachet filler and packaging machines available, designed to cater to different product types, packaging formats, and production requirements. Here are some common types of sachet filler and packaging machines:

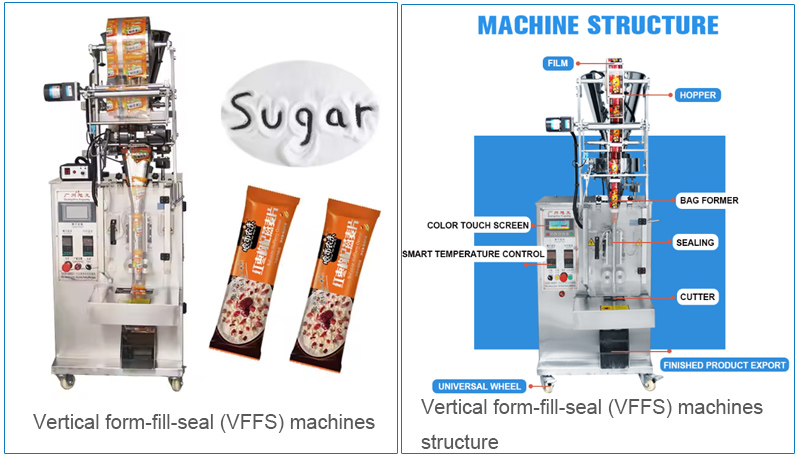

Type 1: Vertical form-fill-seal (VFFS) machines for sale

VFFS machines are widely used for filling and packaging sachets. They form the packaging material into a tube shape, fill it with the product, and then seal it vertically to create individual sachets. VFFS machines are versatile and can handle both liquid and dry products.

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

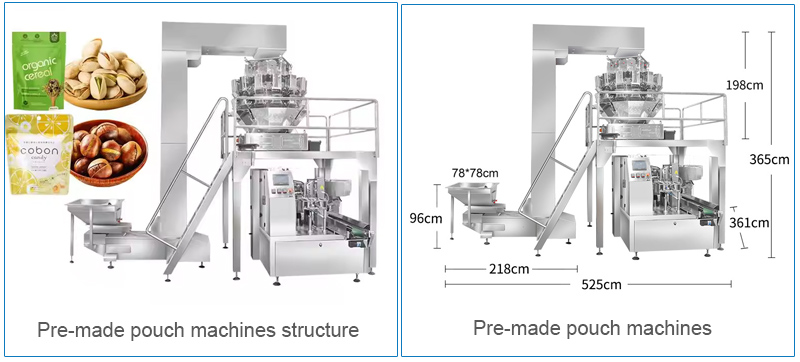

Type 2: Pre-made pouch machines for sale

Pre-made Pouch Machines: Pre-made pouch machines are designed to fill and seal pre-made pouches or sachets. They handle pre-formed pouches and fill them with the desired product before sealing. Pre-made pouch machines offer flexibility in terms of packaging

| Type | TH-420 | TH-520 | TH-720 |

| Bag Length | 80-300mm(L) | 80-400mm(L) | 100-400mm(L) |

| Bag Width | 50-200mm(W) | 80-250mm(W) | 180-350mm(W) |

| Max Width of Roll Film | 420mm | 520mm | 720mm |

| Packing Speed | 5-30bags/min | 5-50bags/min | 5-50bags/min |

| Air Consumption | 0.65Mpa | 0.65Mpa | 0.65Mpa |

| Gas Consumption | 0.3m3/min | 0.4m3/min | 0.4m3/min |

| Power Voltage | 220VAC/50HZ | 220VAC/50HZ | 220VAC/50HZ |

| Dimension | (L)1150*(W)1795*(H)11650mm | (L)1150*(W)1795*(H)11650mm | (L)1780*(W)1350*(H)1950mm |

| Deadwight of Machine | 540KG | 600KG | / |

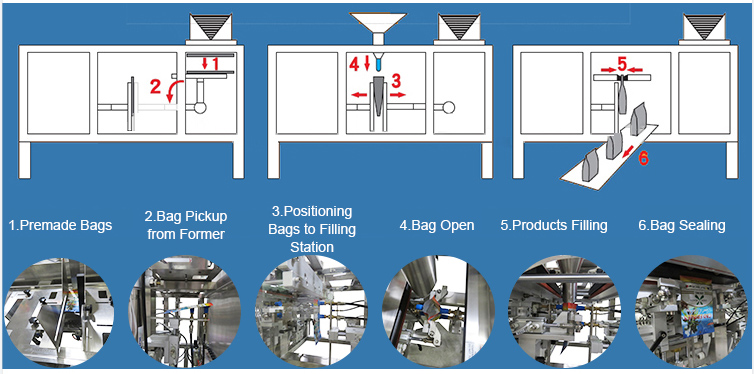

How Sachet Filling and Packaging Machines are Filled and Packaged

The pouch filling machine ensures the accuracy and consistency of the filling amount by accurately filling the product into the pouch. Some pouch filling machines may perform basic sealing operations, but the sealing function is usually not as flexible and efficient as that of a dedicated pouch packaging machine.

After receiving the filled pouches, the pouch packaging machine performs packaging processes such as sealing, date printing and cutting to ensure that the product in the pouch does not leak and the information is complete. The two are used together to complete the production and packaging process of the pouch product, ensuring the integrity and appearance quality of the product.

Customer real shot

What are the characteristics of pouch filling and packaging machines?

Small bag filling and packaging machines are usually small in size and occupy a small area, suitable for production in limited space. Their characteristics include but are not limited to the following:

Versatility: These machines can handle a wide range of products, including liquids, powders, and granules, making them suitable for various industries.

Efficiency and Automation: They offer high production speeds and automated operation, reducing labor costs and increasing productivity.

Consistent Quality: The machines ensure accurate dosing and uniform sealing, leading to consistent product quality and reduced wastage.

Flexibility: They can accommodate different sachet sizes and packaging materials, allowing for customized packaging solutions.

Hygienic and Clean Operation: The machines are designed with sanitary components and enclosed systems, minimizing contamination risks and ensuring product integrity.

Packaging parameters

| Parameter | Powder | Liquid | Granule |

| Bag Size (Width x Length) | 20mm x 30mm to 200mm x 300mm | 20mm x 30mm to 200mm x 300mm | 20mm x 30mm to 200mm x 300mm |

| Filling Range | 2g to 200g | 5ml to 500ml | 2g to 200g |

| Filling Range | 2g to 200g | 5ml to 500ml | 2g to 200g |

| Filling Accuracy | ±1% to ±3% | ±1% to ±3% | ±1% to ±3% |

| Packaging Speed | 30 bags/min to 120 bags/min | 30 bags/min to 120 bags/min | 30bags/min to 120 bags/min |

| Bag Type | Pillowbags,doypacks, et | Pillowbags,stand-up pouches, etc. | Pillow bags, doypacks, etc. |

| Sealing Type | Back seal, three-side seal, etc. | Back seal, three-side seal, etc. | Backseal, three-side seal, etc. |

| Machine Type | Vertical Form Fill Seal (VFFS), pre-made pouch | Vertical Form Fill Seal(VFFS),pre-made pouch | Vertical Form FillSeal (VFFS), pre-made pouch |

What are the applications of sachet filler & packaging machine?

Small bag filling and packaging machines are suitable for the production needs of various small bag packaging products. Small bag filling and packaging machines with different specifications and functions can be customized. The following are some common applications of small bag filling and packaging machines:

Powdered materials: coffee powder, flour, seasoning, powdered pigment, plastic powder, medical powder, etc.

Granular materials: candy, nuts, seeds, plastic granules, chemical granules, etc.

Liquid and semi-fluid materials: soy sauce, beverages, shampoo, lotion, oral liquid, medicine, etc.

Bar or sheet materials: chocolate bars, biscuits, tablets, patches, wet wipes, facial masks, etc.

What are the differences between the use scenarios of small bag filling machines and packaging machines?

The differences between pouch filling machines and pouch packaging machines in their usage scenarios are mainly their functions and application areas. The following are some differences in their usage scenarios.

Pouch filling machines

Suitable for scenarios where products need to be accurately filled into pouches, such as different types of products such as liquids, powders, granules or pastes.

Mainly used in industries such as food, cosmetics, medicines and daily necessities.

Suitable for situations where products need to be accurately filled according to a specific volume or weight.

Suitable for scenarios that require high automation and efficient production to improve production efficiency and accuracy.

Suitable for scenarios where filling is required as a pre-step in the subsequent packaging process.

Pouch packaging machines

Suitable for steps such as packaging, sealing and separation of filled products.

Suitable for packaging of small bag products, such as snacks, candies, dried fruits, medicines, cosmetics, etc. and other products that require small bag packaging.

Different sealing methods can be selected according to product requirements, such as heat sealing, ultrasonic sealing, etc.

Suitable for automated production lines that need to package, seal and separate filled products.

Customer case

| Packaging Case | Packaging products | Customer feedback |

| A coffee producer in Pakistan | Coffee, milk powder, sauce, etc. | Production efficiency increased by 30%, packaging sealing was significantly improved, and product loss was reduced |

| A cosmetics company in Vietnam | Lotion, essence, mask essence, etc. | The packaging appearance is more exquisite, the sealing performance is improved, and the product shelf life is extended |

| A US pharmaceutical company | Powder, granule, liquid medicine. | The packaging accuracy is improved, the production efficiency is improved, and it complies with GMP standards. |

How to choose a sachet filler & packaging machine?

Choosing a sachet filler and packaging machine requires careful consideration of several factors. Here are some key points to consider when selecting a sachet filler and packaging machine:

Packaging Requirements: Determine the specific packaging requirements for your product, such as the desired sachet size, filling volume, and packaging material. Consider the type of product you are packaging (powder, liquid, granules, etc.) and ensure that the machine is suitable for handling and packaging your specific product.

Production Capacity: Assess your production needs and determine the required production capacity of the machine. Consider factors such as the desired output per minute or hour, as well as the machine's capability to handle continuous or intermittent operations.

3.Machine Speed and Efficiency: Evaluate the machine's speed and efficiency in terms of filling and packaging. Consider the machine's filling accuracy, sealing quality, and overall productivity. Look for features such as automatic filling, sealing, and labeling capabilities to streamline the packaging process.

Sachet Filler & Packaging Machine

Dahan small bag filling and packaging machine is committed to providing customers with high-quality and efficient packaging solutions. We have an experienced and professional team that can tailor the most suitable packaging machine solutions for customers. We strictly follow the ISO quality management system standards for production management to ensure stable and reliable product quality and meet or exceed customer expectations. The price is between $790.00-$12,600.00. If you are interested in our small bag filling and packaging machine or have any packaging needs, please feel free to contact us. We look forward to working with you and providing you with high-quality packaging solutions!