What is an economical packaging machine?

Economic packaging machine refers to a packaging machine that is designed to be cost-effective and efficient in terms of packaging operations. It is typically designed with features and functionalities that help optimize resources, reduce waste, and increase productivity while keeping the overall cost of packaging operations low.

Economic packaging machines often utilize cost-effective packaging materials, such as standard films and bags, that are readily available and affordable. They are designed to work efficiently with these materials, providing cost savings in terms of packaging supplies.

Application of economical packaging machine

Food and Beverages: Economical packaging machines are suitable for packaging products such as baked goods, snacks and beverages.

Pharmaceuticals: Can be used to package capsules, tablets and other pharmaceuticals.

Cosmetics: These machines can handle packaging of items such as cosmetics, personal care products, and toiletries.

Electronics: Economical packaging machines can be used to package electronic components, small devices and accessories.

Retail Products: Suitable for consumer packaged goods, apparel and home furnishings.

How does economical packaging machine work?

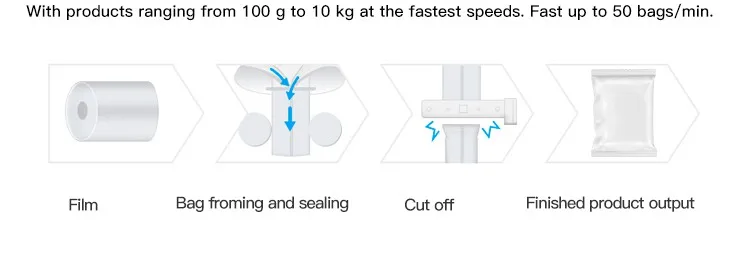

The principle of the economic packaging machine is to transport the product from above to the packaging bag below through vertical movement. It usually includes steps such as loading, measuring, sealing and cutting. During the operation, the product enters the vertical conveying pipe through the feeding device, and then is accurately measured through the metering system. Then the packaging bag is unrolled and formed from the reel, and the product enters the packaging bag through vertical descent, and is finally completed by sealing and shearing. packaging process.

Features of economical packaging machine

Cost-Effectiveness: Economical packaging machines are designed to minimize operating costs such as energy consumption, maintenance and labor requirements. They are often designed to optimize the use of packaging materials and minimize waste.

High Productivity: These machines are designed for high-speed continuous packaging operations, speeding up production cycles and increasing output. They are designed to maximize efficiency and throughput while maintaining product quality.

Versatility: Economical packaging machines are adaptable and capable of handling a variety of packaging formats, sizes and product types. They can accommodate different packaging materials such as films, bags, bottles or cartons, providing flexibility for different packaging needs.

Manual or semi-automatic operation: To keep costs low, economical packaging machines often rely on manual or semi-automatic operation. This means operators may need to manually load product, adjust settings or complete certain steps of the packaging process. While it may require physical labor, it also provides flexibility and control over the packaging process.

Economical packaging machine specifications

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

Structure of economical packaging machine

Economical packaging machines usually feature simple and compact structural designs to achieve cost-effective and efficient packaging operations. It usually consists of a feeding system, a metering system, a packaging bag forming and sealing system, and a control system. The loading system is used to transport products to the working area of the packaging machine, and the metering system is used to accurately measure the weight or capacity of the product. The bag forming and sealing system is responsible for unwinding and forming the bags from the roll, and sealing them by heat sealing or other sealing methods. The control system is used to monitor and control the operation of the packaging machine, including adjusting parameters, setting packaging specifications, and monitoring operating status. The economical packaging machine has a simple structure, is easy to operate and maintain, and is suitable for small and medium-sized enterprises or start-ups to provide economical packaging solutions.

Customer case

![[field:title/]](/uploads/231228/1-23122QH30b27.png)