What is granules packaging machine?

Granules Packaging Machine is a type of equipment specifically designed to package granular or particulate products. It is commonly used in industries such as food, pharmaceuticals, chemicals, and agriculture, where products like grains, seeds, nuts, fertilizers, and various granular materials need to be efficiently packaged.

Granules packaging machine adopts a microcomputer control system, which can adjust the heating temperature, set the bag length, and automatically run the film. The weighing filling machine cooperates with the bag making machine to achieve fast packaging speed and save manpower. .Automatic, semi-automatic and custom filling machines are available. According to customer needs, the bag types can be changed: back seal, three sides seal, four side seal.

3 types of granule pouch packaging machine for sale

There are several types of automatic granule pouch packing machines available in the market. Here are three common types:

Vertical Form Fill Seal (VFFS) Machine: This type of machine forms a pouch from a roll of packaging film, fills it with granules, and then seals it. It typically has a vertical configuration where the film is pulled downward to create the pouch. VFFS machines offer high-speed operation, precise filling, and various sealing options.

Pre-made Pouch Filling and Sealing Machine: This type of machine is designed to fill and seal pre-made pouches with granules. It works by opening the pre-made pouch, filling it with granules through a dosing system, and then sealing it. This machine is suitable for various pouch styles, such as stand-up pouches, flat pouches, and zipper pouches.

Multi-Head Weigher Packing Equipment: Multi-head weigher packing equipment is a highly efficient and accurate packaging solution widely used in various industries, including food, pharmaceuticals, and chemicals. It utilizes multiple weighing heads, usually ranging from 8 to 32, to simultaneously measure and dispense precise quantities of granular or small piece products into individual packages.

Looking for more about granules packaging machine

-

Automatic Rice Packing Machine

It efficiently removes rice from storage containers and measures and packages it according to preset packaging specifications. This type of machine usually delivers the rice grains to a weighing device via a conveyor belt system, where it is then packaged according to a set weight.

-

Candy Wrapping Machine

It effectively packages individual candies or small candy bars in various types of packaging materials, such as plastic film or foil. The machine operates through a conveyor system that transports the candies to the packaging station, where they are carefully packaged and sealed.

-

Chocolate Packing Machine

It efficiently and accurately packages individual chocolate bars, truffles or other chocolate products in various types of packaging materials such as foil, paper or plastic film. The machine operates through a conveyor system that transports the chocolates to a packaging station.

How does granules packaging machine work?

The working principle of the granule packaging machine mainly includes the following steps:

Material supply: The granular materials are first put into the hopper, and then the feeding mechanism distributes the materials into each packaging bag according to a certain distribution ratio according to the set control system.

Measuring: The measuring mechanism is controlled by photoelectric switches or other sensors to transfer the determined amount of material to the next step through conveyor belts and other devices.

Sealing: After the measurement is completed, the granular materials will be transferred to the sealing mechanism, which will seal the materials. For high-level granular packaging machines, there may also be multiple layers of sealing.

Conveying: Finally, the conveying mechanism conveys the packaged materials to the equipment for the next step of operation.

What are the applications of granules packaging machine?

Granule packaging machines can be used to package various granular materials, including but not limited to the following types of granules:

Food industry: used for packaging granular foods such as rice, grains, beans, salt, sugar, nuts, dried fruits, coffee, etc.

Chemical industry: used for packaging rubber granules, plastic granules, fertilizer granules, chemical granules, etc.

Pharmaceutical industry: used for packaging Chinese medicine granules, Western medicine granules, health care product granules, etc.

Agriculture and feed industry: used for packaging feed granules, seeds, fertilizer granules, etc.

Other industries: including building material granules (such as cement granules), metal granules, decorations, toys, etc.

Customer Videos

What are the features of granules packaging machine?

Granule packaging machines have some unique features when handling granular products, which help to improve packaging efficiency, ensure packaging quality and adapt to different types of granular products. The following are some of the features of granule packaging machines:

It can automatically complete the functions of bag-making, measuring, feeding, filling, sealing, cutting, counting, and printing, and can increase the function of easy tearing.

Step-less frequency adjustment can install different feeding systems and can be used for packing granule, liquid, and powder products.

The top granule packaging machine has a simple structure and reasonable design. Therefore, it is easy to install, operate, and maintain.

With an advanced PLC control system and 5-inch color touch screen, easy operation, and efficient performance.

Full 304 stainless steel machine housing.

Backside sealing/ 3 sides sealing available.

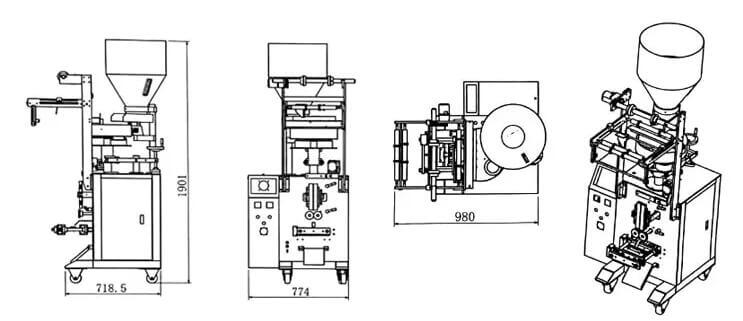

Granules packaging machine specifications

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

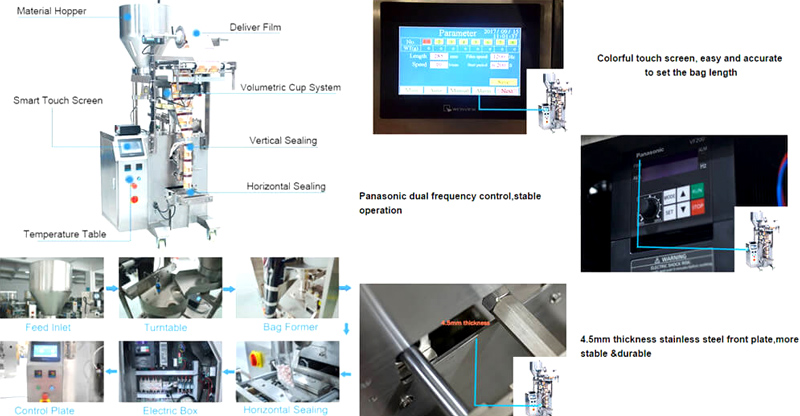

What are the structures of granules packaging machine?

These components of the granule packaging machine together constitute the structure of the granule packaging machine. Through the coordination of their respective functions, accurate packaging and efficient production of granular products can be achieved. The main components and structures are as follows:

Feeding system: This part is responsible for conveying granular materials from storage bins or containers to the working area of the packaging machine.

Measuring system: Used to accurately measure the weight or quantity of granular materials in each packaging unit to ensure the accuracy and consistency of packaging.

Bag conveying system: Conveys pre-made bags to the packaging area and prepares to fill granular materials.

Particle filling system: Fills the measured granular materials into the packaging bags, which can usually be adjusted according to the size and shape of the packaging bags.

Sealing system: Seals the packaging bags to ensure that the granular materials will not leak or be contaminated by the outside world.

Bag forming system: Forms the roll or pre-made packaging bag into a bag shape suitable for filling granular materials.

Granules packaging machine customer case

A large fertilizer manufacturer uses Granules Packaging Machine to automatically package nitrogen fertilizer and phosphate fertilizer, increasing the packaging speed by 30%, reducing dependence on manual labor, and ensuring that the weight of each bag is consistent, reducing material waste.

A nut and grain production company uses Granules Packaging Machine to quantitatively package nuts, packaging 30 bags per minute, using vacuum packaging to extend the shelf life of the product and ensure food safety.

A plastic recycling company ordered Granules Packaging Machine to package recycled plastic particles. Fully automated packaging reduces manual intervention, improves efficiency, and standardized packaging facilitates storage.

A chemical raw material production company uses Granules Packaging Machine to quantitatively package chemical raw materials, ensuring the accurate weight of each bag, optimizing the packaging process, and reducing waste.

A seed production company purchased Granules Packaging Machine, which is used to automatically package various seeds, increasing the speed by 50%, reducing seed loss, and maintaining variety purity.

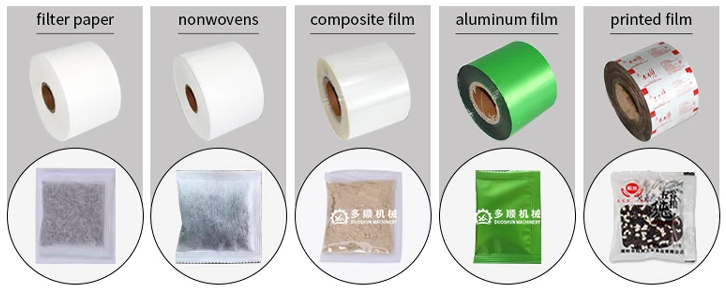

Packing material

Polyester/aluminizing/Polyethylene, polypropylene/polyethylene aluminum foil/Polyethylene, nylon/Enhanced polyethylene, tea-leaf filtering paper, paper/Polyethylene, etc.

Available options

A variety of accessories can be added to the granule packaging machine to enhance its functionality and adapt to different packaging needs. Here are some common add-ons you can add:

Weighing device: used to accurately weigh and measure particles to ensure a consistent number of particles in each packaging bag.

Sealing machine: used to automatically seal packaging bags to ensure sealing and product freshness.

Conveyor belt system: used to automatically transport particles to the packaging site to improve production efficiency.

Sensors and control systems: used to monitor and control parameters during the packaging process, such as packaging speed, temperature and pressure.

These accessories can be selected and configured according to specific packaging needs to meet the different requirements of particle packaging and improve production efficiency and product quality.

How to choose a granule packaging machine?

Choosing the right granule packaging machine involves considering various factors to ensure it meets your specific requirements. Here are some key factors to consider when selecting a granule packaging machine:

Packaging Requirements: Determine the specific packaging requirements for your granular product, such as the desired packaging format (pouches, bags, etc.), packaging material, weight range, and packaging speed.

Machine Type: There are different types of granule packaging machines available, such as vertical form fill seal (VFFS) machines, pre-made pouch filling and sealing machines, and rotary fill seal machines. Evaluate the pros and cons of each type based on your production needs, packaging style, and desired automation level.

Production Capacity: Consider your production volume and speed requirements. Choose a machine that can handle the desired output, whether it's a smaller machine for low-volume production or a high-speed machine for large-scale production.

Automation and Integration: Determine the level of automation you require based on your production process. Fully automated machines can streamline operations, reduce labor costs, and enhance efficiency. Additionally, consider the compatibility and integration of the machine with other equipment in your production line.

What is the granule packing machine price?

Dahan Granule Packaging Machine Manufacturer is committed to providing customers with high-quality and efficient packaging solutions. We have many years of experience in packaging machinery manufacturing, and our technical team is experienced and can customize granule packaging machines of various specifications and functions according to customer needs. Our granule packaging machines use advanced technology and high-quality components, introduce the latest packaging technology, and improve the performance and efficiency of the equipment to meet the changing needs of customers. We can also customize packaging machines according to the special needs of customers, including different packaging specifications, special functional requirements, etc. The price is generally $495.00-$13,000.00. If you are interested in our products or have any questions, please feel free to contact us, we will wholeheartedly provide you with support and help.

Granule pouch packing machine manufacturers

Xinxiang Dahan Granule Packaging Machine Manufacturer is a well-known enterprise specializing in the manufacturing of granule packaging machines. They have many years of experience and technical expertise and a good reputation in the field of granule packaging machines. They offer various models of high-quality granule packaging machines that can meet the packaging needs of different industries. Xinxiang Dahan granule packaging machine manufacturer focuses on product quality, reliability and customer service, providing customers with a full range of support and solutions.