What is a combined weighing and packaging machine with a vacuum feeder?

Combined weighing and packaging machine with vacuum feeder is an advanced and efficient system designed for automating the weighing, filling, and packaging of various products in various industries. It integrates a vacuum feeder, weighing system, and packaging machine to streamline the entire packaging process.

The combined weighing and packaging machine with a vacuum feeder is a specialized equipment used for automatically weighing and packaging various products, including granules, powders, or small items. The vacuum feeder is a key component that assists in the efficient and precise transfer of the product from the storage source to the weighing and packaging sections.

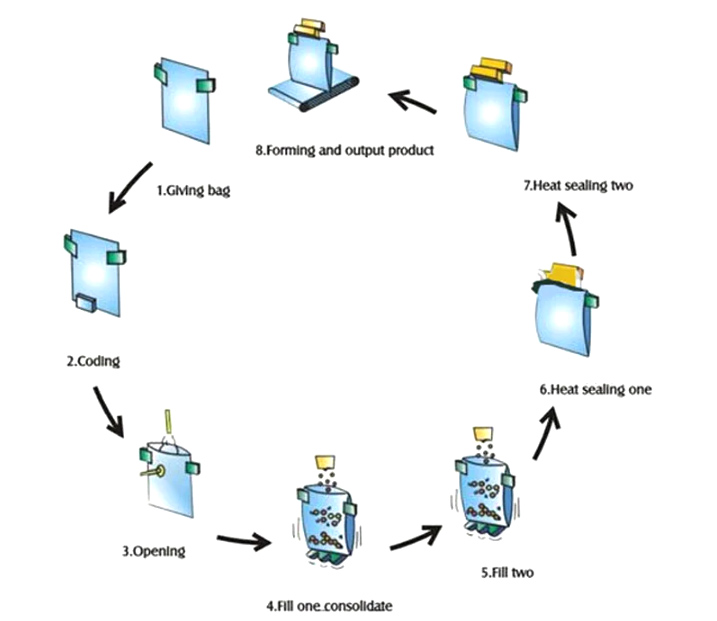

How does combined weighing and packaging machine with a vacuum feeder work?

Product Feeding: The product to be packaged is stored in a bulk storage area or hopper. The vacuum feeder creates a controlled suction or vacuum force to transport the product from the storage source to the weighing section.

Weighing: The machine is equipped with a weighing system that measures the desired weight of the product. The vacuum feeder releases the product into a weighing pan or bucket placed on a scale. The weighing system ensures accurate and consistent product quantities for each package.

Dispensing: Once the desired weight is achieved, the vacuum feeder stops the suction or vacuum force, and the product is discharged from the weighing pan into the packaging material, such as bags, pouches, or containers.

Packaging: The packaging material is formed, sealed, and cut to create individual packages. This can be done using various packaging techniques, such as vertical form-fill-seal (VFFS) or horizontal form-fill-seal (HFFS) methods.

Conveyor Movement: After packaging, the products are moved along a conveyor system for further process

Features of combined weighing and packaging machine with a vacuum feeder

1. Automation and Efficiency: Automates the entire weighing and packaging process, reducing manual labor and increasing productivity.Streamlines operations, enhances production efficiency, and reduces production downtime.

2. Accuracy and Consistency: Precise weighing system ensures accurate weight measurements, reducing product giveaway and maintaining consistent product quality.The vacuum feeder ensures gentle handling and prevents product damage, preserving product integrity.

3. Versatility: Capable of handling products of various sizes, shapes, and weights.

Easily integrates with different packaging machines to accommodate different packaging requirements.Suitable for a wide range of industries, including food, pharmaceutical, chemical, and more.

4. Sanitary and Hygienic Design: Constructed with food-grade materials that comply with industry standards.Easy to clean and maintain, promoting a clean and hygienic production environment.

Combined weighing and packaging machine with a vacuum feeder specifications

Multi-head weigher packing machine parameters

| Type | DH-420 | DH-520 | DH-720 |

| Bag length | 80-300mm | 80-400mm | 100-400mm |

| Bag width | 50-200mm | 80-250mm | 180-350mm |

| Max width of roll film | 420mm | 520mm | 720mm |

| Packing speed | 5-30bags/min | 5-50bags/min | 5-50bags/min |

| Air consumption | 0.65mpa | 0.65mpa | 0.65mpa |

| Gas consumption | 0.3m³/min | 0.4m³/min | 0.4m³/min |

| Power voltage | 220V | 220VAC/50HZ | 220VAC/50HZ |

| Dimension | (L)1320*(W)950*(H)1360 | (L)1150×(W)1795×(H)1650mm | (L)1780×(W)1350×(H)1950mm |

Vacuum feeder parameters

| Model | power kw |

Hopper volume L |

Air pressure Mpa |

Capacity kg/h |

| DH-1 | 1.5 | 12 | 0.4-0.6 | 400 |

| DH-2 | 2.2 | 12 | 600 | |

| DH-3 | 3.0 | 18 | 1200 | |

| DH-4 | 5.5 | 40 | 2500 | |

| DH-6 | 7.5 | 40 | 4000 | |

| DH-7 | 7.5 | 90 | 6000 |

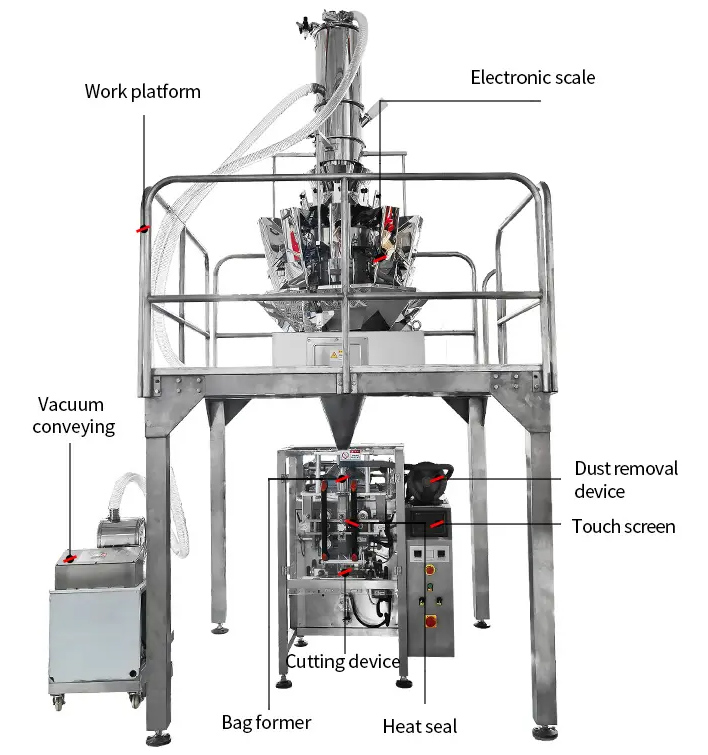

Structure of combined weighing and packaging machine with a vacuum feeder

1. Vacuum Feeder:

- Equipped with a powerful vacuum system that gently picks up individual products from a bulk source.

- Accurately conveys products to the weighing system while maintaining their integrity.

- Prevents product damage and ensures consistent feeding.

2. Weighing System:

- High-precision load cells and sensors accurately weigh products to meet desired target weight.

- Adjusts the feeding rate to achieve precise weight measurements.

- Minimizes product giveaway and helps maintain consistent product quality.

3. Packaging Machine:

- Integrated with the weighing system to receive weighed products.

- Depending on the application, various packaging options are available, such as bagging, pouching, or container filling.

- Seals and packages products efficiently, ensuring product integrity and preservation.

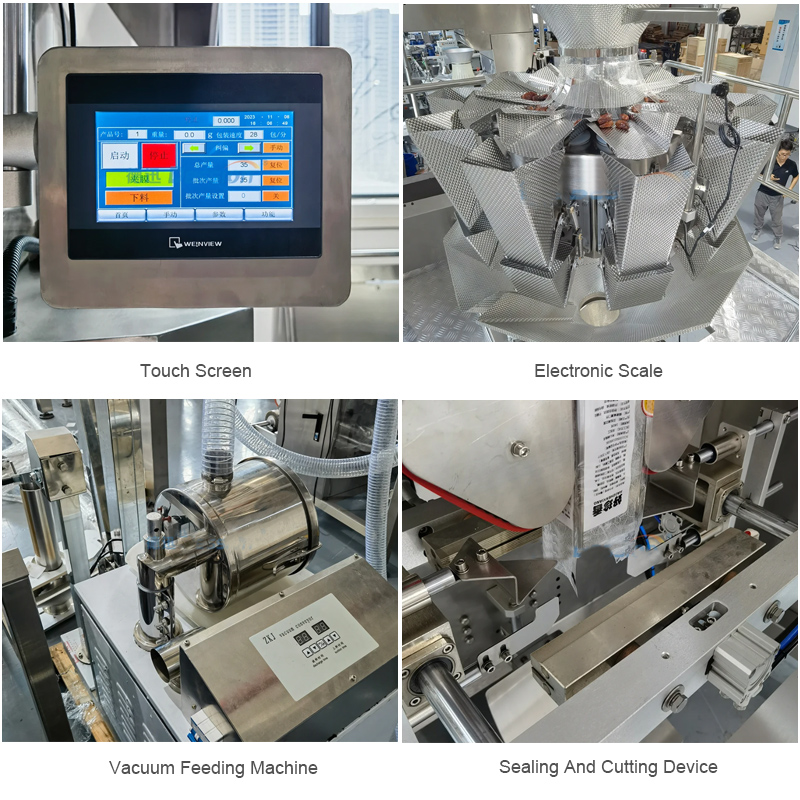

Main parts of combined weighing and packaging machine with a vacuum feeder show

What are the applications of combined weighing and packaging machine with a vacuum feeder

1. Food Industry: Weighing and packaging snacks, confectioneries, grains, and other food items.

2. Pharmaceutical Industry: Packaging tablets, capsules, powders, and other pharmaceutical products.

3. Chemical Industry: Packaging chemicals, powders, granules, and other hazardous materials.

4. Hardware Industry: Packaging nuts, bolts, screws, and other small hardware components.

5. Cosmetics Industry: Packaging beauty products, such as powders, creams, and lotions.

6. Electronic Industry: Packaging electronic components, such as resistors, capacitors, and semiconductors.

Customer case

Combined weighing and packaging machine with a vacuum feeder in the factory