What is a twin packaging system?

Twin packaging system is a type of packaging machinery that is designed to enhance productivity and efficiency by incorporating two packaging lines into a single system. It enables simultaneous packaging of multiple products or two different packaging formats, offering increased throughput and flexibility.

The twin packaging system is widely used in various industries, including food and beverage, pharmaceuticals, cosmetics, and consumer goods. It offers increased efficiency, productivity, and flexibility, making it an ideal solution for manufacturers looking to optimize their packaging processes and meet evolving market demands.

How does twin packaging system work?

1.Product Feeding: The products to be packaged are fed into the system through the product feeding systems. These systems can use conveyors, vibratory feeders, or other methods to transport the products to each packaging line.

2.Weighing and Filling: Each packaging line is equipped with its own weighing and filling system. These systems accurately measure the desired amount of product and dispense it into the packaging material. The weighing systems ensure precise weight measurements for consistent packaging.

3.Packaging Process: The packaging machines in each line, such as vertical form-fill-seal (VFFS) machines or horizontal form-fill-seal (HFFS) machines, form the packaging material into bags or containers, fill them with the measured product, and seal them. The packaging process is synchronized and controlled by the system's control systems.

4.Conveyor Systems: After the products are packaged, conveyor systems transport them from each packaging line to subsequent stages of the packaging process or to the final packaging area. These conveyor systems ensure a smooth flow of products and facilitate efficient handling and distribution.

5.Control and Monitoring: The control systems of the Twin Packaging System manage and coordinate the operation of the two packaging lines. They synchronize the actions of the packaging machines, monitor the packaging process, and adjust parameters as needed. The control systems may also integrate with other equipment, such as checkweighers or labeling machines, for additional functionalities.

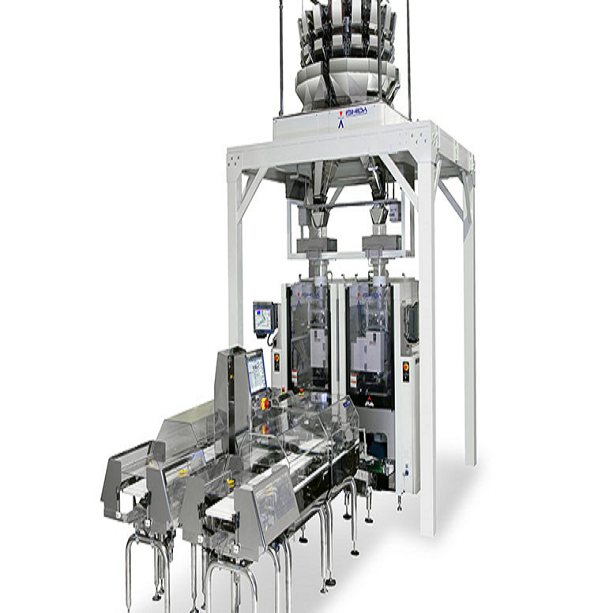

Customer site

Features of twin packaging system

Dual Packaging Lines: The system consists of two independent packaging lines operating side by side within a single machine. Each line has its own set of components, such as filling mechanisms, sealing units, and control systems.

Increased Throughput: With two packaging lines, the Twin Packaging System allows for higher production output compared to a single packaging system. It reduces the time required for packaging multiple products or different formats, improving overall efficiency.

Flexibility and Versatility: The system offers flexibility to package different products simultaneously or to accommodate different packaging formats on each line. This versatility is especially beneficial for manufacturers dealing with multiple product variations or packaging requirements.

Space Saving: By integrating two packaging lines into a single machine, the Twin Packaging System helps optimize floor space utilization. It is particularly advantageous for facilities with limited space, allowing for efficient production without the need for additional equipment.

Synchronization and Control: The Twin Packaging System employs advanced control systems to synchronize the operation of the two packaging lines. This ensures proper coordination between the lines, maintaining consistent performance and minimizing errors.

Twin packaging system specifications

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

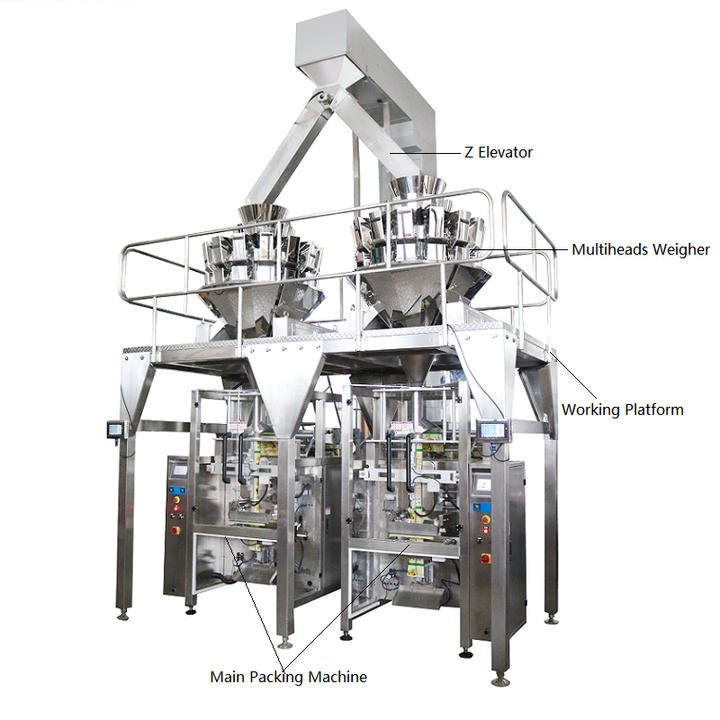

Structure of twin packaging system

The structure of a twin packaging system typically consists of a sturdy framework that houses two independent packaging lines. The system is designed to optimize space utilization and ensure efficient operation. Each packaging line within the structure has its own set of components, including product feeding mechanisms, filling systems, sealing units, labeling modules, and control systems. The structure may feature a central control panel or human-machine interface (HMI) that allows operators to monitor and control the packaging process of both lines simultaneously. The overall design of the twin packaging system prioritizes synchronization and coordination between the two lines to maintain consistent performance and maximize productivity.

What are the applications of twin packaging system?

The twin packaging system finds applications in various industries that require high-volume and flexible packaging solutions. Some common applications of the twin packaging system include:

Food and Beverage: The system is used for simultaneous packaging of different food products such as snacks, confectionery items, frozen foods, sauces, and beverages. It enables efficient packaging of multiple product variations or different packaging formats.

Pharmaceutical and Healthcare: In the pharmaceutical industry, the twin packaging system is employed for packaging different medications, tablets, capsules, or medical devices simultaneously. It allows for efficient packaging of various drug formulations or dosage strengths.

Cosmetics and Personal Care: The system is utilized for packaging multiple cosmetic products, including creams, lotions, gels, and beauty products. It enables simultaneous packaging of different formulations, sizes, or packaging designs.

Household and Consumer Goods: The twin packaging system is applied in packaging household and consumer goods such as cleaning agents, detergents, toiletries, and pet care products. It allows for efficient packaging of different product variations or packaging formats simultaneously.

Industrial and Automotive: In the industrial and automotive sectors, the system is used for packaging components, spare parts, or small manufactured goods. It facilitates simultaneous packaging of multiple items, ensuring efficient handling and distribution.

E-commerce and Retail: The twin packaging system is employed in e-commerce and retail sectors for packaging a variety of products simultaneously. It enables efficient packaging of different products or packaging formats to meet the demands of online shopping and retail distribution.

Customer case

| Customer case | Customer needs | Solution | Customer feedback |

| A large snack food manufacturer. | This customer needed to increase the productivity of its potato chip packaging line while reducing waste caused by packaging errors. | Introducing a dual packaging system that can process two packaging lines simultaneously, achieving high-speed, precise packaging. In addition, the system is equipped with an advanced visual inspection system that can automatically detect and reject unqualified products. | Production efficiency increased by 40%; packaging error rate decreased by 90%; and waste of raw materials and packaging materials was significantly reduced. |

| A multinational pharmaceutical company | The client required rigorous packaging for its pharmaceutical products to ensure product safety and meet strict regulatory requirements. | The double packaging system is equipped with high-precision weighing and metering functions to ensure the accurate dosage of each medicine. In addition, the system is also equipped with a traceability system that can record the production and packaging information of each product to achieve full traceability. | Ensures the accuracy and safety of drug packaging; meets strict regulatory requirements; and improves customer confidence in product quality. |

| A well-known daily chemical product manufacturer achieves diversified packaging | The customer needs to respond flexibly to market demands and achieve diversified product packaging to meet the needs of different consumers. | Deploy a dual packaging system that is highly flexible and can quickly switch between different packaging specifications and forms. In addition, the system supports a variety of packaging materials to meet the packaging needs of different products. | It has achieved the diversification of product packaging to meet the needs of different consumers; improved the flexibility of the production line to quickly respond to market changes; and increased the competitiveness of products in the market. |