How Does Vertical Packaging Machines Work?

Vertical packaging machines, also known as vertical form-fill-seal (VFFS) machines, work in a sequential process to form, fill, and seal flexible bags or pouches in a vertical orientation.

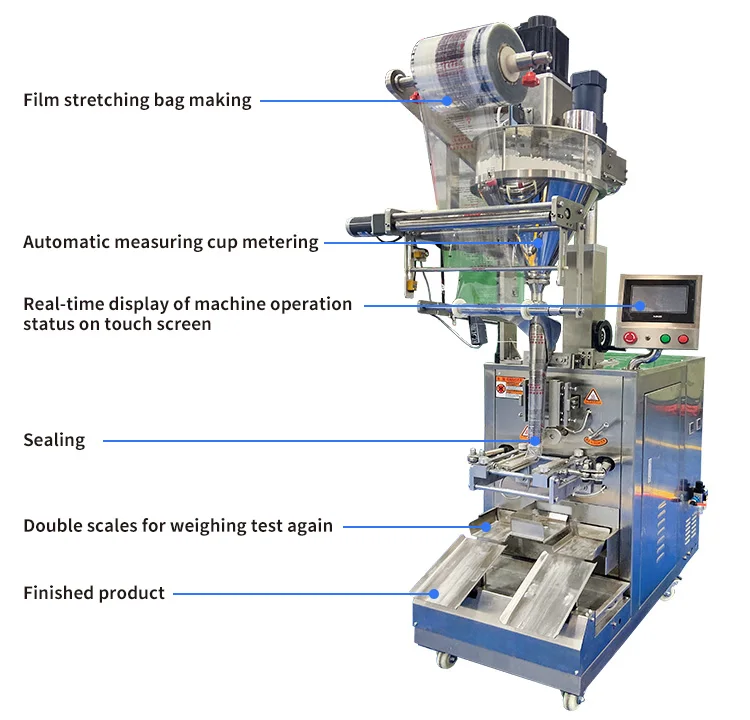

Vertical packaging machines usually consist of the following main parts: coating roll support, coating roll tensioning system, bag forming system, product feeding system, sealing system, cutting system and control system. The coordinated work of these components allows the vertical packaging machine to efficiently complete the steps of film forming, product feeding, sealing and cutting, achieving a continuous vertical packaging process.

Here is a step-by-step explanation of how vertical packaging machines typically operate:

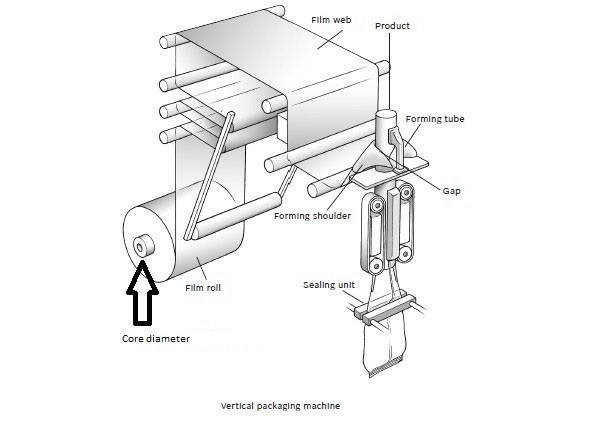

1.Film Unwinding: The packaging film or material is unwound from a roll and guided into the machine.

2.Bag Forming: The film passes through a series of rollers and guides, which shape it into a vertical tube or cylinder. The film edges are sealed longitudinally to create a continuous tube.

3.Product Filling: The formed tube descends, and the bottom end is sealed temporarily. The product is then dispensed into the open end of the tube through a filling mechanism. The filling mechanism can be a volumetric filler, weigher, auger, pump, or other suitable device, depending on the product being packaged.

4.Bag Sealing: Once the product is filled, the open end of the tube is sealed transversely to create a bag. The sealing mechanism can use heat sealing, ultrasonic sealing, or other sealing methods. The seal ensures that the contents are securely enclosed.

5.Bag Cutting: The sealed bag is cut off from the continuous tube by a cutting mechanism, creating an individual bag. The cutting can be done with a knife, hot wire, or other cutting devices.

6.Bag Discharge: The finished bag is discharged from the machine, usually onto a conveyor belt or a collection tray for further processing or packaging.

7.Control System: The machine's operation is controlled by a control system, which manages and coordinates various functions such as bag length, filling volume, sealing temperature, cutting speed, and other parameters. It ensures precise control and synchronization of the packaging process.

Vertical packaging machines offer several advantages, including:

High Efficiency: They can achieve high packaging speeds, allowing for increased production rates.

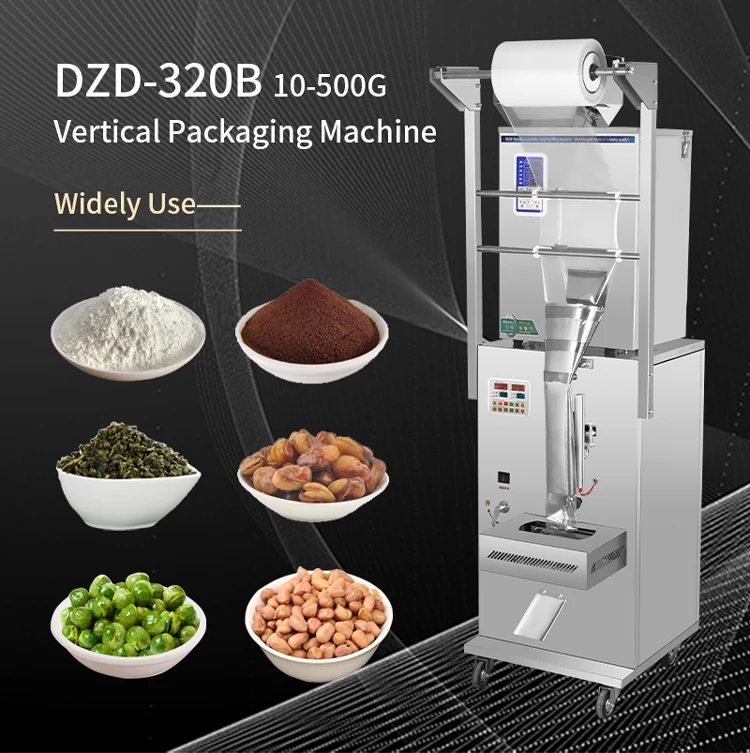

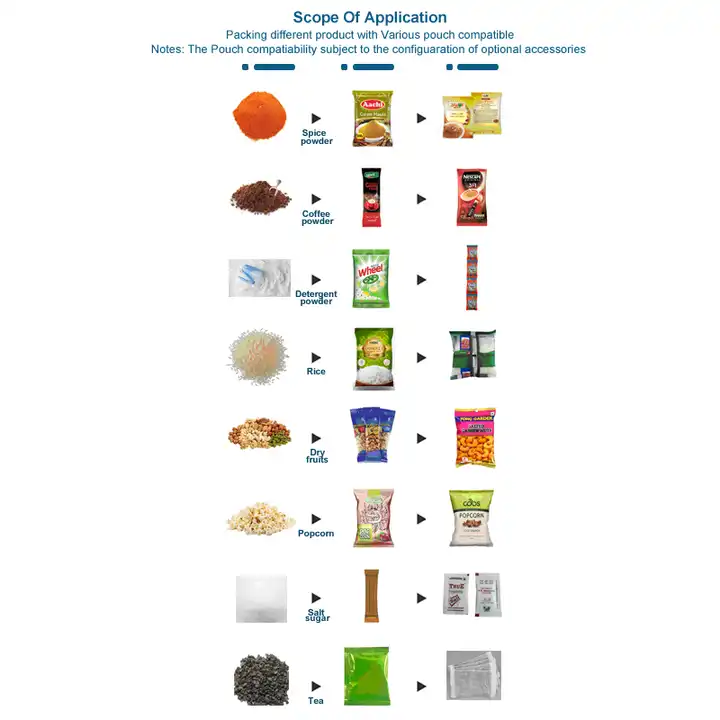

Versatility: These machines can handle a wide range of product types, sizes, and bag styles, offering flexibility in packaging options.

Space-saving Design: Vertical machines have a compact footprint, making them suitable for limited space environments.

Improved Product Protection: The sealed bags provide excellent product protection, preserving freshness, preventing contamination, and extending shelf life.

Vertical packaging machines are designed to operate efficiently and continuously, allowing for high-speed production and consistent packaging results. The machines can handle various bag sizes, film materials, and product types. They offer versatility, reliability, and automation, making them widely used in the food, pharmaceutical, and consumer goods industries for efficient and hygienic packaging.

Tuesday December-26 2023 11:39:31