What is FFS Pouch Pacaking Machine?

FFS (Form-Fill-Seal) pouch packing machine is a type of packaging machine that integrates the processes of forming, filling, and sealing pouches in a single automated system. It is widely used in the packaging industry for efficiently packaging various products.

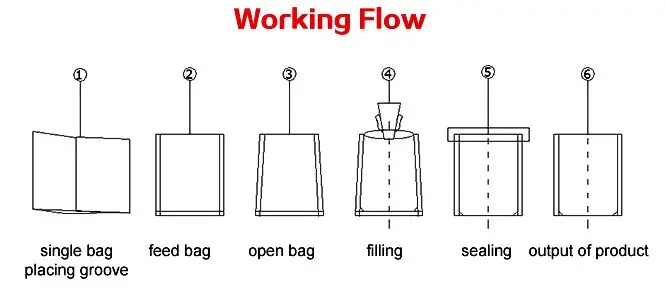

Here's a breakdown of the three main steps involved in the FFS process:

1.Forming: In the forming stage, the machine takes a flat roll of packaging film or a web of film material and shapes it into a pouch or bag. The film is typically fed through a series of rollers and guided into the desired shape, such as a pillow bag or a stand-up pouch, depending on the application requirements.

2.illing: Once the pouch is formed, the FFS packaging amachine moves on to the filling stage. The product to be packaged is dispensed into the formed pouch through a filling system. This can include volumetric fillers, auger fillers, liquid pumps, or other mechanisms, depending on the nature of the product being packaged.

3.Sealing: After the pouch is filled, the FFS machine proceeds to the sealing stage. The open end of the pouch is sealed to create a secure and airtight closure. This is typically done using heat sealing, where the edges of the film are heated and pressed together to form the seal. The sealing process may also involve cutting the pouches apart from the continuous film roll.

FFS (Form-Fill-Seal) pouch packing machines offer several advantages in the packaging industry. Here are some of their key benefits:

1.Efficiency and Speed: FFS pouch packing machines are highly automated, which allows for fast and efficient packaging processes. They can form, fill, and seal pouches in a continuous and uninterrupted manner, resulting in high production speeds and increased output.

2.Cost-Effectiveness: FFS machines eliminate the need for separate equipment for forming, filling, and sealing pouches, reducing the overall cost of packaging operations. The integration of these processes into a single machine streamlines production and reduces labor requirements, leading to cost savings for manufacturers.

3.Product Protection: FFS pouch packing machines provide effective sealing, ensuring product freshness and extending shelf life. The airtight seals created by these machines help protect the contents from moisture, oxygen, and other external factors that could potentially compromise product quality.

4.Hygiene and Safety: FFS machines incorporate sanitary design features and adhere to strict quality standards, making them suitable for packaging food, pharmaceuticals, and other sensitive products. They minimize the risk of contamination and ensure the safety and integrity of the packaged goods.

5.Reduced Material Waste: FFS machines optimize film usage by precisely measuring and cutting the packaging material, minimizing waste. This contributes to cost savings and improves sustainability by reducing the consumption of packaging materials.

What products can be packed by FFS pouch packing machine?

FFS (Form-Fill-Seal) pouch packaging machines can be used to package a variety of products, covering multiple industries and product types. Here are some common product categories:

1. Food and snacks: FFS packaging machine is suitable for packaging various food and snack products such as puffed food, nuts, candies, potato chips, pastries, biscuits, coffee beans, tea, etc.

2. Cosmetics and personal care products: FFS packaging machines can be used to package various cosmetics and personal care products such as cosmetics, shampoo, shower gel, skin care products, lipstick, perfume, etc.

3. Household items: FFS packaging machine is suitable for packaging household items such as washing powder, detergent, dishwashing liquid, cleaners, aromatherapy products, candles, and wet wipes.

4. Medicines and health care products: FFS packaging machines can be used to package medicines, health care products, vitamins, herbal formulas, medical dressings and other pharmaceutical and health care products.

5. Liquid and powder products: FFS packaging machine is suitable for packaging liquid and powder products such as juice, milk, beverages, oil, condiments, protein powder, milk powder, flour, sugar powder, etc.

6. Industrial and chemical products: FFS packaging machine can be used to package chemical products, lubricants, milk

The FFS pouch packing machine offers several advantages, including high production speeds, automation, and the ability to create custom-shaped pouches. It is commonly used for packaging various products such as snacks, powders, liquids, granules, and many other items across different industries.

Thursday January-18 2024 08:59:47