Automatic Forming Powder for Filling And Sealing Machine

Thursday July-04 2024 15:37:24

Automatic Forming Powder for Filling And Sealing Machine, also known as VFFS packaging machine, is an efficient, high-quality and safe packaging equipment. Automatic Forming Powder for Filling And Sealing Machine is widely used in food, chemical, pharmaceutical, pesticide, feed and other industries, and is an important equipment for the production of powder products.

What are the types of automatic powder forming filling and sealing machines?

The automatic powder forming, filling and sealing machine is a highly automated equipment specially used for the packaging of powder products. Different types of packaging can show different product advantages. The following are different types of powder filling and sealing machines.

Type 1: Vertical automatic powder forming, filling and sealing machine This type of automatic powder forming, filling and sealing machine is suitable for small batch production scenarios and can meet the production needs of small and medium-sized enterprises. It can package coffee powder, tea powder, flour, protein powder, seasoning powder, pharmaceutical powder, etc.

Type 2: Horizontal automatic powder forming, filling and sealing machine The horizontal automatic powder forming, filling and sealing machine is suitable for large-scale production and can achieve high-speed and continuous production operations. It can package milk powder, food additives, health care powder, cosmetic powder, hot pot base powder, pesticide powder, etc.

Type 3: Multi-head automatic powder forming, filling and sealing machine Multi-head automatic powder forming, filling and sealing machine is suitable for production needs that require processing multiple products or products of multiple specifications at the same time. It can package beverage powders of various flavors, milk tea powders of various formulas, makeup powders of various colors, traditional Chinese medicine powders of various herbal formulas, instant soup powders of various flavors, etc.

What is the use of automatic powder forming, filling and sealing machine?

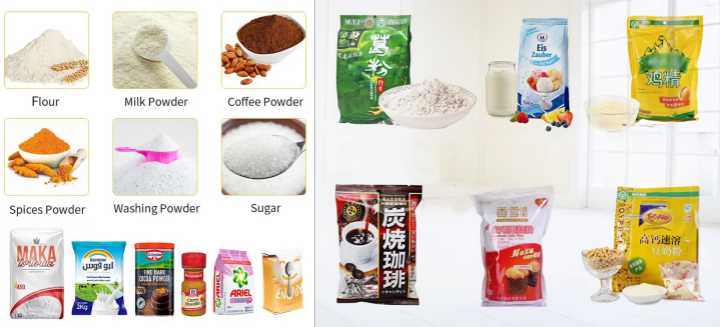

Food industry: Automatic powder forming, filling and sealing machines can be used to package various food powders, such as coffee powder, tea powder, milk powder, seasoning powder, flour, etc.

Pharmaceutical industry: In the pharmaceutical industry, automatic powder forming, filling and sealing machines are used to package various medicinal powders, such as herbal powder, medical powder, health care powder, etc.

Cosmetics industry: Automatic powder forming, filling and sealing machines are widely used in the cosmetics industry for the packaging of cosmetic powders, mask powders, loose powders and other products.

Agrochemical industry: Automatic powder forming, filling and sealing machines are also used to package pesticide powders, fertilizer powders and other agrochemical products.

Other industries: Automatic powder forming, filling and sealing machines can also be used in other industries, such as the chemical industry, building materials industry, etc., for packaging powdered chemical products, building materials, etc.

What is the process of automatic powder forming, filling and sealing machine?

The automatic forming powder filling and sealing machine is an automatic packaging equipment that integrates automatic forming, filling and sealing functions, and is specially used to handle the packaging process of powder products. This equipment completes the packaging of powder products quickly and efficiently through a series of steps, including raw material supply, forming, filling, sealing, testing and inspection, as well as labeling and packaging.

Features of automatic powder forming filling and sealing machine

*50L side-opening hopper, easy to clean.

*50-500g bag powder packaging.

*Servo motor drives the screw conveyor with high precision.

*There is a stirrer on the hopper to ensure that the powdered material fills the screw conveyor.

*Chinese/English, PLC touch screen, customizable local language.

*Reasonable mechanical structure, easy replacement of size parts, easy cleaning.

*The machine has filling, weighing, bag making, sealing, cutting and coding functions.

Specifications

| Model: | JS-420F | JS-520F | JS-620F | JS-720F |

| Packingmaterial | Opp/cpp OPP/PE PET/PE NILO/PE PE | Opp/cpp OPP/PE PET/PE NILO/PE PE | Opp/cpp OPP/PE PET/PE NILO/PE PE | Opp/cpp OPP/PE PET/PE NILO/PE PE |

| FilmWidth: | Max.420mm | Max.520mm | Max.620mm | Max.720mm |

|

Bag

Length:

|

80-300mm | 80-350mm | 90-450mm | 100-500mm |

| BagWidth: | 50-200mm | 80-250mm | 170-300mm | 180-350mm |

| Film RollDiameter: | Max.320mm | Max.320mm | Max.320mm | Max.320mm |

| PackingSpeed: | 5-60bag/min | 5-60bag/min | 5-55bag/min | 5-55bag/min |

| Power | 220V 50/60HZ 2KW | 220V 50/60HZ 3KW | 220V 50/60HZ 3KW | 220V 50/60HZ 3KW |

| Dimension | (L)1217*(W)1015*(H)1343MM | (L)1150*(W)1795*(H)1650MM | (L)1150*(W)1795*(H)1650MM | (L)1800*(W)1250*(H)1780M |

| Netweight | About540kg | About 600kg | About700kg | About750kg |

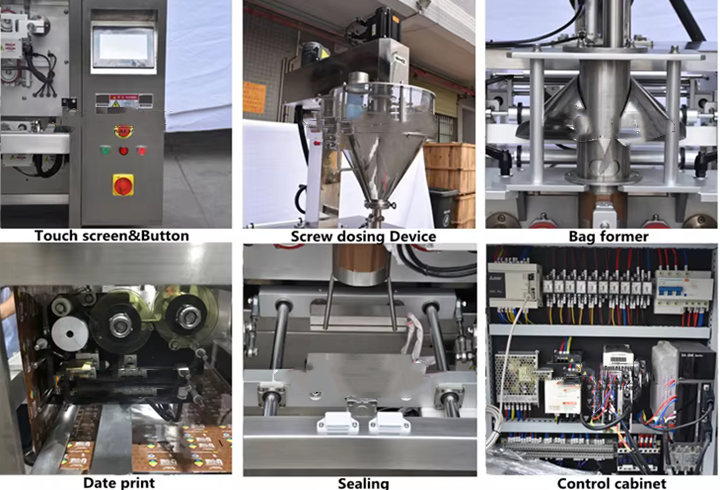

Powder automatic forming filling sealing machine structure

The structure of the automatic powder forming filling sealing machine usually includes raw material supply system, forming device, filling device, sealing device, control system and detection and inspection system. This structure enables the automatic powder forming filling sealing machine to achieve efficient, accurate and stable powder packaging process.

Customer site

The automatic powder forming filling sealing machine uses advanced technology and automation devices to improve the packaging efficiency, accuracy and consistency of powder products, while ensuring the quality and sanitation and safety of the products. If you are interested in this equipment and want to learn more or make a purchase, please feel free to contact us. We will wholeheartedly provide you with professional consulting services and quotations to help you choose the appropriate automatic powder forming filling sealing machine. Looking forward to working with you!