What is powder filling and sealing machine?

Powder filling and sealing machines automates the process of accurately filling containers with powdered products and sealing them securely, ensuring efficiency, accuracy, and product integrity in the packaging process.Powder filling and sealing machines are commonly used in industries such as food, pharmaceuticals, chemicals, and cosmetics.

Powder Filling And Sealing Machine supports various types and sizes of containers, bottles, jars, pouches, or sachets. They are flexible in packaging design and support customized options such as labeling, coding, and printing, which can be customized according to different powder requirements.

What are the types of powder filling and sealing machines?

There are various types of powder filling and sealing machines available for sale, depending on the specific requirements of your packaging needs. Here are some common types of powder filling and sealing machines:

Powder Sachet Filling and Sealing Machine: This machine is specifically designed to fill and seal powder products into individual sachets. Sachets are small, flat packets typically made of flexible packaging material. Powder sachet filling and sealing machines are commonly used for single-serving powder products such as seasoning mixes, instant coffee, powdered drinks, and spices.

Powder Pouch Filling and Sealing Machine: This machine is designed to fill and seal powder products into larger pouches. Pouches are typically made of flexible packaging material and can have various sizes and shapes. Powder pouch filling and sealing machines are used for packaging medium to large quantities of powdered products such as detergent powders, protein powders, powdered supplements, and powdered food ingredients.

Powder Bag Filling and Sealing Machine: This machine is suitable for filling and sealing powder products into bags of different sizes and styles. Bags can range from small bags with a resealable zipper closure to larger bags with heat-sealed closures. Powder bag filling and sealing machines are used for various powdered products like flour, sugar, salt, pet food, and industrial powders.

Work live shooting

What are the functions of Powder Filling And Sealing Machine

The powder filling and sealing machine serves several important functions in the packaging process of powdered products. Here are some key functions of this machine:

Precise metering and filling: It can accurately meter and fill powder to ensure the correct amount of powder in each packaging unit, avoiding waste and inconsistency.

Applicable to a variety of packaging specifications: It is suitable for packaging containers of different sizes and shapes, such as bags, cans, etc.

Sealing and sealing: The powder filling and sealing machine can automatically complete the sealing and sealing operations to ensure the freshness and quality of powder products and prevent the products from being damp or contaminated.

Flexibility and customization: It can be customized according to customer needs to meet the packaging requirements of different powder products, such as different powder types, packaging specifications and packaging materials.

Reduce waste: The filling and sealing machine can accurately control the filling amount of powder, reduce overfilling or waste, improve product utilization and reduce production costs.

How does the powder filling and sealing machine work?

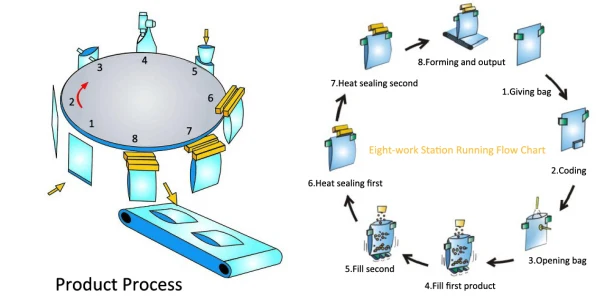

A powder filling and sealing machine works by first dispensing the powdered product from a hopper into the designated packaging format, such as sachets, pouches, or bags. The machine utilizes precise filling mechanisms, such as augers, volumetric cups, or weighers, to ensure accurate measurement and filling of the powder. Once the desired amount of powder is dispensed, the machine proceeds to seal the packaging format.

Powder filling and sealing machine specifications

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

Structure of powder filling and sealing machine

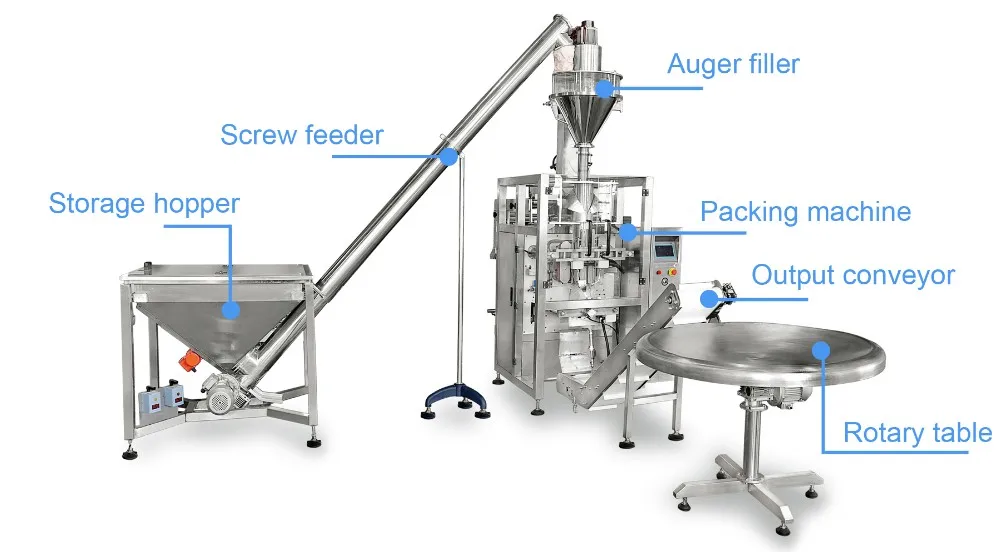

The structure of a Powder Filling And Sealing Machine includes a hopper to hold the powder, a filling system (such as an auger or volumetric cup) for precise dispensing, a container handling system (usually a conveyor belt) to move and position the package, a sealing mechanism to form a hermetic seal (using heat, ultrasound or other methods), and a control system (PLC/HMI) to automate and monitor the entire process.

Hopper: The hopper is a container that holds the powdered product. It has a controlled outlet to regulate the flow of powder into the filling system.

Filling System: The filling system is responsible for accurately measuring and dispensing the desired amount of powder into the containers. It can use various methods such as auger filling, volumetric filling, or combination weighing to achieve precise dosing.

Conveyor System: A conveyor system transports the containers to the filling station and then to the sealing station. It ensures a continuous and efficient flow of containers throughout the packaging process.

Sealing System: The sealing system securely seals the containers to prevent leakage and maintain product freshness. Common sealing methods include heat sealing, ultrasonic sealing, or induction sealing, depending on the packaging requirements.

Control System: The control system, often based on PLC technology, manages and monitors the machine's operation. It controls the filling quantity, sealing parameters, conveyor speed, and other variables to ensure accurate and consistent packaging.

What is the use of powder filling and sealing machine?

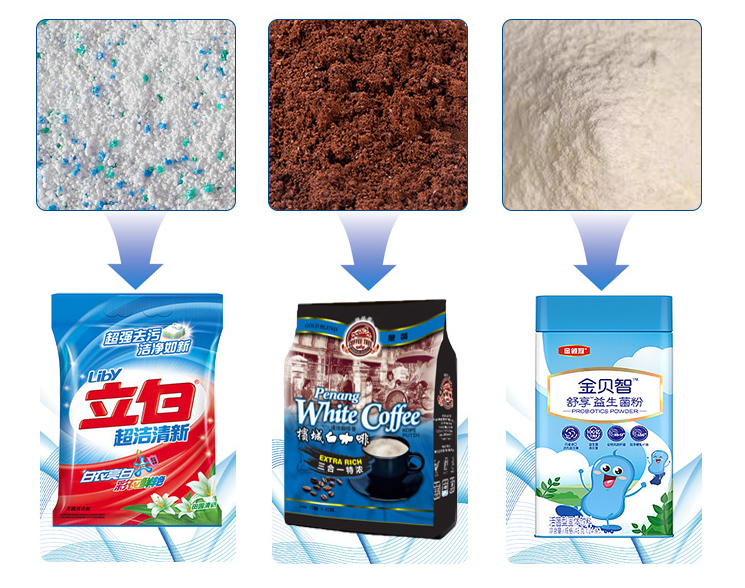

Powder filling and sealing machines can handle a wide range of powdered products. Some examples of powders commonly processed by these machines include:

Food Powders: This category includes products like spices, seasonings, powdered beverages (coffee, tea, cocoa), powdered milk, protein powders, flour, baking mixes, powdered sugar, and food additives.

Pharmaceutical Powders: These machines are used to package powdered medications, herbal supplements, vitamins, and other pharmaceutical powders.

Chemical Powders: Powder filling and sealing machines can handle various chemical powders such as detergents, fertilizers, pesticides, powdered pigments, and powdered additives for various industries.

Nutraceutical Powders: Powdered supplements, probiotics, vitamins, and dietary powders can be efficiently filled and sealed using these machines.

Industrial Powders: Powder filling and sealing machines are also used for packaging industrial powders, such as construction materials (cement, grout), metal powders, and powdered chemicals used in manufacturing processes.

Customer case

| Packaging Case | Zhejiang customers pack starch powder | Philippines customers packing coffee powder | European customer vial powder filling production line |

| Requirements | A food processing company needs high-precision and high-efficiency powder filling equipment for packaging flour, milk powder, food additives and other products | The coffee powder filling and sealing machine provided by a food machinery company is suitable for filling and sealing containers of different specifications, and supports a variety of filling methods such as self-flow, filling, measuring cup, negative pressure, and screw. | A pharmaceutical company needs fully automatic powder filling and sealing equipment for filling, capping, rolling, locking and sealing of vials of powder |

| Solutions | The powder quantitative filling machine provided by Dahan has the functions of automatic quantitative, automatic filling, and automatic adjustment of measurement errors. It adopts microcomputer control and hybrid stepper motor drive technology to ensure high precision and low noise. | The equipment can complete fully automatic operations such as cup delivery, filling, liquid level control, cap placement, double sealing, cup pushing, and conveying. It is suitable for filling and sealing a variety of products such as coffee powder, wine, jelly, milk, etc. | Dahan's supplier provides a fully automatic production line that supports customized needs and ensures that the filling accuracy and sealing quality meet the high standards of the pharmaceutical industry. |

| The equipment supports quick replacement of metering screw components to meet the packaging needs of different materials and specifications. The adjustment can be completed in just 10 minutes without affecting the normal operation of the production line. | The production capacity is 6000-8500 cups/hour, the filling capacity can be customized, the whole machine power is 11KW, suitable for large-scale production needs | The production line is highly integrated, easy to operate, suitable for large-scale production, and complies with GMP regulations |

Things you need to consider when buying a powder filling and sealing machine

When buying a powder filling and sealing machine, there are several important factors to consider. Here are some key considerations:

Packaging Requirements: Determine the specific packaging format you require, such as sachets, pouches, or bags. Consider the size, shape, and material of the packaging, as well as any special features like resealable closures or tear notches.

Powder Characteristics: Evaluate the properties of the powder, including its flowability, density, and particle size. Ensure that the machine you choose is capable of handling your specific powder's characteristics to ensure accurate and consistent filling.

Production Volume: Consider your production requirements in terms of output capacity. Determine the speed and efficiency of the machine, as well as its ability to handle high-volume production without compromising quality.

Accuracy and Precision: Look for a machine that offers precise filling mechanisms to ensure accurate measurement and consistency in fill weights. This is especially important for products with strict dosage requirements or where product consistency is crucial.

Want to know the powder filling and sealing machine price?

Dahan Powder Packaging Machine is a company specializing in the sale of powder filling and sealing machines. With many years of industry experience, it is committed to providing customized, advanced technology and multifunctional packaging solutions. The price is generally between $790.00 and $12,600.00. We can provide a full range of services, including pre-sales consultation, in-sales support and after-sales guarantee, to ensure that customers get high-quality and efficient production experience. If you have any needs, please feel free to contact us!

Why choose us as your top powder filling and sealing machine supplier?

Xinxiang Dahan is a manufacturer specializing in the production of powder filling and sealing machines. They offer various models and specifications of machines suitable for different powder products and packaging needs. Xinxiang Dahan is known for its high-quality equipment, reliable performance and excellent after-sales service, providing customers with customized solutions and ensuring the best balance of production efficiency and product quality.