Food Packaging Machine for Bread

Food Packaging Machine for Bread is a mechanical equipment specially used for packaging bread and bread products. It has the function of automatically completing the counting, dividing, packaging and sealing of bread, and its flexibility is widely applicable to small batch production. food packaging machine for bread design that does not require water or compressed air connection makes it more flexible in the production environment, and due to the wide range of equipment options, it can be customized for specific needs of customers.

Live video

What are the advantages of Food Packaging Machine for Bread?

Automated operation: The machine can automatically complete a series of processes such as conveying, packaging, sealing and cutting of bread, without a lot of manual operation, significantly improving the packaging speed.

High-speed packaging: It can pack 120 loaves of bread per minute, far exceeding the efficiency of manual packaging, and can run continuously for a long time, reducing downtime and human errors.

Consistent packaging: The machine packaging size is uniform and the sealing is good, ensuring the consistent packaging quality of each loaf.

Extended shelf life: The use of appropriate packaging materials and sealing technology can effectively isolate air, moisture and pollutants, extend the freshness and shelf life of bread, and reduce waste.

(Optional) Modified atmosphere packaging: Some high-end equipment can achieve modified atmosphere packaging (MAP), by filling inert gases such as nitrogen and carbon dioxide, further inhibiting the growth of microorganisms and extending the shelf life of food.

How does Food Packaging Machine for Bread work?

A typical Food Packaging Machine for Bread automates the process of wrapping and sealing bread loaves to maintain freshness and prepare them for sale. Imagine a conveyor belt where sliced or whole loaves are fed into the machine. The machine then takes a roll of packaging film (often plastic), forms it around the bread to create a bag, removes excess air, and seals the ends using heat or clips. Some machines also include features for date coding or applying labels. The visual would show bread entering one end, moving through the wrapping and sealing stages within the machine's enclosed structure, and a finished, packaged loaf exiting at the other end.

Food Packaging Machine for Bread Parameter

| Model | Bag-Making Size(mm) | Sealing Method | Measuring range(ml) | Power(kw) | Capacity(bags/min) | Weight(kg) | Dimension(L*W*H) mm |

| FX6320H | L:50-200W:50-140 | Back Seal | 20-400 | 1.2 | 35-90 | 300 | 650*900*1640 |

| FX6320L | L:50-200W:50-120 | Three-side Seal | 5-100 | 1.2 | 35-90 | 300 | 650*900*1640 |

| FX6320HD | L:50-160W:50-120 | Four-side Seal | 30-80 | 1.5 | 35-80 | 300 | 650*900*1640 |

| FX6430 | L:80-300W:80-180 | Back Seal | 30-60 | 1.8 | 30-60 | 380 | 900*1200*2100 |

| FX50LC | L:30-50W:30-60 | Single Liquid | 30-60 | 1.5 | 30-60 | 300 | 650*900*1640 |

| FX6400 | L:(30-40)*4W:(30-50)*4 | 4Article Liquid | (30-45 )*4 | 2 | (30-45 )*4 | 380 | 900*1200*2100 |

| FX6320E | L:50-160W:50-80 | Three-side Seal | 35-60 | 1.5 | 35-60 | 350 | 650*900*1665 |

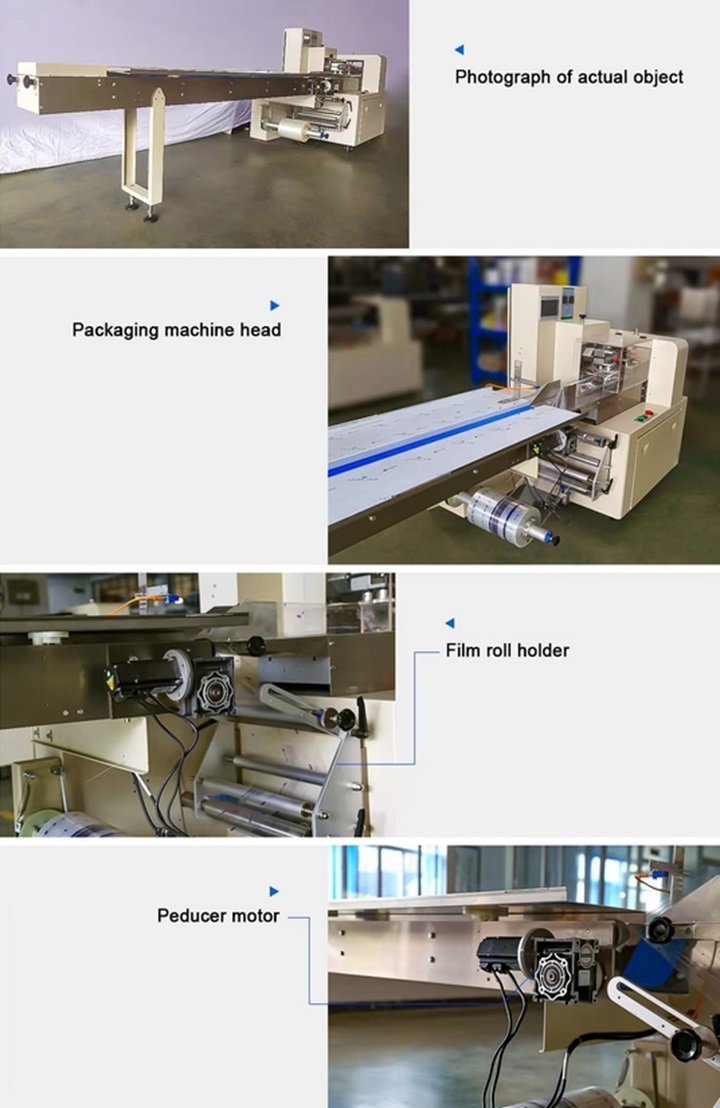

What are the structures of Food Packaging Machine for Bread?

Food Packaging Machine for Bread structure The structure of the Food Packaging Machine for Bread includes the feeding system, metering system, packaging system and control system, which work together to realize the automated packaging process of bread.

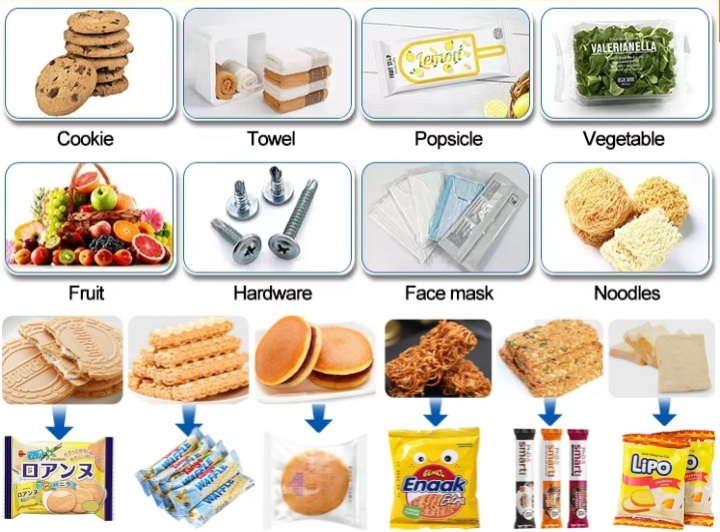

What are the applications of Food Packaging Machine for Bread?

Bread: sliced toast, hamburger buns, dinner rolls, croissants, donuts, baguettes, etc.

Cakes and desserts: sponge cakes, mousse cups, muffins, Swiss rolls, puffs, etc.

Casual baked goods: meat floss biscuits, egg yolk crisps, waffles, biscuits, energy bars, etc.

Frozen dough and semi-finished products: frozen bread bases, pizza bases, puff pastry, etc., need to be packaged in anti-freeze and moisture-proof packaging.

Food Packaging Machine for Bread Customer Case

| Application scenario | Packing volume | Packing speed | Packing size | Packing bag material |

| A well-known bread production company uses a fully automatic bread additive packaging machine for quantitative packaging of baked goods such as bread and cakes to ensure product hygiene and extend shelf life. | 50,000 bags/day | 60-80 bags/minute | 50mm × 80mm (small bag) to 100mm × 150mm (large bag) | Food-grade PE/PP composite film, with moisture-proof and anti-oxidation functions |

| A large Chinese snack food company (such as Panpan and Xu Fuji) uses an automatic material sorting line for automated packaging of products such as small bread and meat floss biscuits to reduce manual intervention. | 30,000 bags/hour | 120 bags/minute | 60mm × 100mm (pillow bag) or 80mm × 120mm (hanging bag). | PET/AL/PE composite film, heat-sealable and puncture-resistant. |

| A high-end cake brand uses LY-380 fully automatic transparent film three-dimensional packaging machine to improve product display and preservation performance. | 20,000 pieces/day | 40-60 pieces/minute | 100mm × 100mm × 50mm (three-dimensional box) or 150mm × 200mm (long bread) | Degradable transparent BOPP film, in line with environmental protection requirements. |

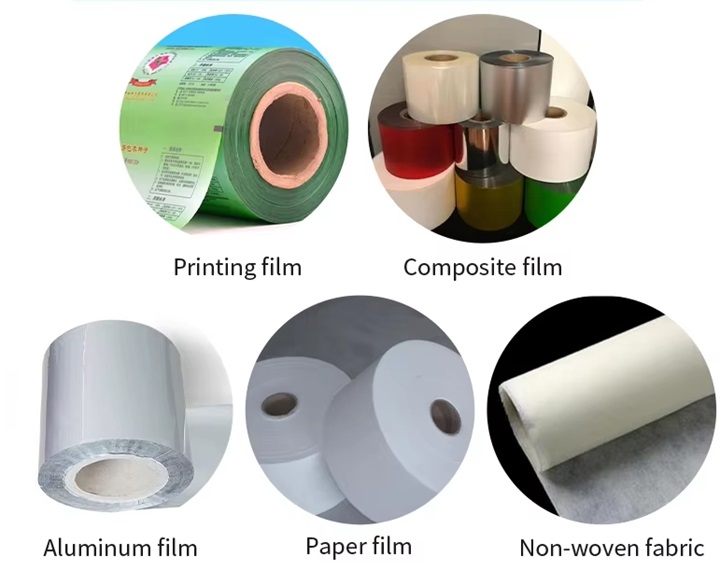

What is used to package bread?

Bread can be packaged in a variety of materials, including plastic bags, paper bags, paper boxes, and packaging films. Plastic bags are usually made of plastic materials such as polyethylene (PE) or polypropylene (PP), which provide moisture-proof, sealing, and transparent display functions. Choosing the right bread packaging material requires considering the characteristics of the bread, freshness requirements, sustainability, and consumer preferences.

Optional Devices

The packaging machine has date coding,fills the package with nitrogen,makes the linking bag, makes the easy tearing and pinches the package.

How to choose a Food Packaging Machine for Bread

When choosing a Food Packaging Machine for Bread, you need to consider factors such as production scale, packaging requirements, machine performance and reliability. Consider packaging speed, ability to adapt to different bread sizes, ease of operation and maintenance, compliance with hygiene standards, and the supplier's reputation and after-sales service. Through comprehensive evaluation, choosing the right Food Packaging Machine for Bread will help improve production efficiency, ensure packaging quality, and meet the needs of the company.

How much does a Food Packaging Machine for Bread cost

The price of a Food Packaging Machine for Bread varies depending on many factors, including brand, specifications, functions, production capacity, and market supply and demand. Generally speaking, the price of a Food Packaging Machine for Bread ranges widely, from a few thousand dollars to hundreds of thousands of dollars. Simple manual or semi-automatic packaging machines are cheaper, while high-speed, fully automatic, and multi-functional Food Packaging Machine for Breads are more expensive. In addition, special requirements, customization, and additional equipment will also affect the price.

Wednesday, April 23, 2025 15:54:51