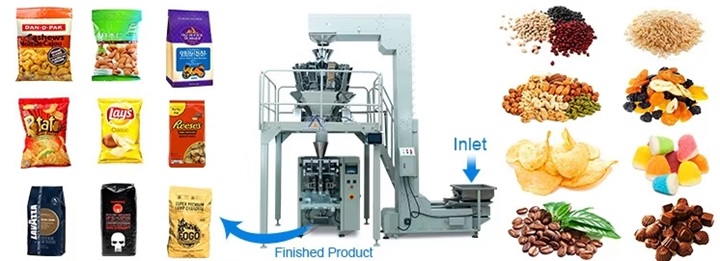

Food Packaging Machine for Snacks

Food Packaging Machine for Snacks is a kind of equipment specially used for packaging snack products. It has automation function and can complete the packaging process of snacks. packaging machine snack food can be used to pack peanuts, melon seeds, broad beans, chocolate, popcorn, cereal, rice skin, plum candy, red dates, coffee beans, cherry jam and other snack products. Snack packaging machine plays a very important role in the packaging process of snack industry.

What are the Types of Food Packaging Machine for Snacks?

We supply granule packaging machines and pillow packaging machines, which are designed for snack packaging. Our product line includes granule packaging machine models, pillow packaging machines, and vacuum packaging machines for foods that require vacuum packaging. We support customized services. If you are interested in snack food packaging equipment, please feel free to contact us for more details.

| Product categories | Packaging speed (pack/min) | Packaging volume (g/pack) | Packaging size (mm) | Features |

| Vertical Form Fill Seal (VFFS) | 20-100+ | 1-5000+ | Bag width: 50-300, bag length: 50-400 | Wide application range, can package various forms of snacks such as granules, powders, liquids, sauces, etc.; various packaging forms, such as back seal, three-side seal, four-side seal, self-supporting bag, etc.; high degree of automation, can integrate metering, filling, sealing, coding and other functions. |

| Horizontal pillow packaging machine | 30-200+ | 1-unlimited | Bag width: 30-200, bag length: 50-unlimited | Mainly suitable for regular or irregular shaped solid snacks, such as biscuits, bread, candy, chocolate bars, etc.; fast packaging speed, flat and beautiful packaging effect; the packaging length can be adjusted according to the product size. |

| Bag-feeding packaging machine | 15-60+ | 1-5000+ | Customized according to pre-made bag size | Pre-made bags are used for packaging, with high packaging quality and beautiful sealing; various special-shaped bags can be packaged; suitable for snacks that require higher-end packaging, such as freeze-dried snacks, nut gift packs, etc.; zippers, nozzles and other functions can be integrated. |

| Weighing packaging machine | 20-80+ | 10-5000+ | Customized according to bag size | Use multi-head combination scale or linear scale for precise measurement, suitable for granular and block snacks with high weight accuracy requirements, such as potato chips, nuts, candies, etc.; high measurement accuracy, reducing material waste. |

| Filling packaging machine | 20-100+ | 1-500+ | Customized according to container size | Mainly used for packaging liquid or sauce snacks, such as sauces, jams, etc.; can be filled by volumetric, piston, peristaltic pump and other filling methods; packaging can be bagged or bottled. |

| Heat shrink packaging machine | 10-50+ | Customized according to product and film size | Customized according to product and film size | Usually used as secondary packaging, multiple small packages or bulk snacks are packaged together to form a larger sales unit for easy transportation and sales; the packaging is compact, moisture-proof and dust-proof, and improves the appearance of the product. |

| Vacuum packaging machine | 5-30+ | Customized according to product and bag size | Customized according to product and bag size | By vacuuming to remove the air in the packaging bag, the shelf life of snacks can be extended to prevent oxidation and deterioration; suitable for snacks that need to be kept fresh, such as cooked food, meat products, and soy products. |

| Pillow-type three-dimensional packaging machine | 20-80+ | Customized according to product size | Customized according to product size | The packaging form is three-dimensional and beautiful, and is often used for single or multiple packaging of candy, chocolate and other products. It can also be used for packaging of small bags of puffed food; the packaging has good sealing performance and can effectively protect the product. |

What are the advantages of Food Packaging Machine for Snacks?

Boosts Efficiency: Faster packaging speeds than manual work, increasing output.

Ensures Food Safety: Minimizes contamination, maintains hygiene standards.

Cuts Costs: Reduces labor expenses and material waste.

Offers Versatility: Handles various snacks and packaging types. Such as: potato chips, nuts, biscuits and other powder, granule, block snacks

What are the applications of Food Packaging Machine for Snacks?

Common packaged snack types:

Salty snacks: potato chips, corn chips, pretzels, popcorn, cheese balls, crackers, nuts (peanuts, almonds, cashews, etc.), seeds (sunflower seeds, pumpkin, etc.), jerky (beef jerky, turkey jerky, etc.), puffed snacks (cheese puffs, corn rolls)

Sweet snacks: candy (hard candy, soft candy, chocolate), cookies, granola bars, fruit snacks, cereal bars, dried fruit (raisins, dried apricots, etc.)

Other snacks: assorted nuts, yogurt cups, dips and sauces (single servings), meat snacks, cheese sticks

Food Packaging Machine for Snacks Parameters

| Model | GQ-420 | GQ-520 | GQ-720 |

| Speed | Max 80bags /min | Max 50bags /min | Max 40 bags /min |

| Bag Size |

width:50-300ml Length:60-200ml |

Width:80-350ml Length:80-250ml |

Width:100-350ml Length:100-450ml |

| Width of film | 420mm | 520mm | 720mm |

| Rang | Max 1300ml | Max 2000ml | Max 4000ml |

| Power | 220v 2.5kw 50-60HZ | 220v 2.2kw 50-60HZ | 220v 4kw 50-60HZ |

| Size |

L1400×W970× H1600mm |

L1430×W1200× H1700mm |

L1780×W1350× H2050mm |

What are the structural components of Food Packaging Machine for Snacks?

Food Packaging Machine for Snacks usually consist of a feeding system, a metering system, a packaging bag forming system, a filling system, a sealing system, a control system, a discharge system and other components that work together to realize an automated snack packaging process and improve packaging efficiency and quality.

What are the packaging types and materials of Food Packaging Machine for Snacks?

Packaging Bag Material

Food Packaging Machines for Snacks commonly use plastic films like polypropylene (PP), polyethylene (PE), polyester (PET), and metallized films (VMPET, VMPP) for their barrier properties, sealability, and cost-effectiveness, often in single layers or laminations to achieve specific characteristics; other materials include aluminum foil for high barrier, paper-based options (sometimes coated), and increasingly, sustainable alternatives like biodegradable polymers and recyclable mono-layer films.

What type of packaging is used for snacks?

Packaging finished products

What is the price of Food Packaging Machine for Snacks?

Particle packaging machine, pillow packaging machine, their internal structures and devices are varied, and the prices are also very different. The filling process of the granule packaging machine is controlled by a photoelectric detector through vibration. The pillow packaging machine is equipped with a feeding platform and a heat sealing cutter. The cutters include single cutters, double cutters and third cutters.

In addition, if you have requirements for these devices, date printers, chain bag equipment, nitrogen filling devices and hole flushers with healing seals and cutters are also provided. In short, the price of the snack packaging machine depends on the equipment you choose. Contact us for more details.

Why choose us as your top packing machine supplier?

Henan Dahan Machinery Co., Ltd. has a highly professional workforce and has long been focused on the manufacture of packaging machines. With excellent quality, advanced packaging technology, competitive prices and satisfactory services, the company has successfully completed many orders from all over the world. Products undergo strict inspections before shipment to ensure that customers receive high-quality and good-performance machines. The company provides customized services, gives helpful suggestions based on customer needs, and is committed to meeting customers' specific requirements. By contacting Henan Dahan Machinery Co., Ltd., customers can get professional support and customized solutions to meet their specific packaging needs.

Food Packaging Machine for Snacks Customer Cases

| Application scenario | Packing volume | Packing speed | Packing size | Packing bag material |

| A large-scale potato chip automated packaging production line needs to pack potato chips into retail bags at high speed and stability. | 50g/bag | 80 bags/minute | Width 150 mm, length 220 mm | Aluminum-coated polypropylene composite film (VMPP) has excellent barrier properties, preventing potato chips from getting damp and deteriorating, and maintaining a crispy taste. |

| Quantitative packaging of a variety of mixed nuts requires the ability to handle nuts of different shapes and sizes and ensure the accurate weight of each bag. | 100g/bag | 45 bags/minute | Width 180 mm, length 250 mm, self-supporting bag with zipper | PET/PE composite film has good strength and barrier properties, and the self-supporting bag format is convenient for consumers to repeatedly seal and eat. |

| Single pillow packaging and multiple collective packaging of small hard candies. | 200g/bag | 60 bags/minute | Width 160mm, length 240mm | BOPP/CPP composite film, ensuring certain barrier properties and strength. |

Wednesday September-03 2025 18:20:24