Small Full Auto Feed Packaging Machine

Wednesday January-24 2024 18:06:26

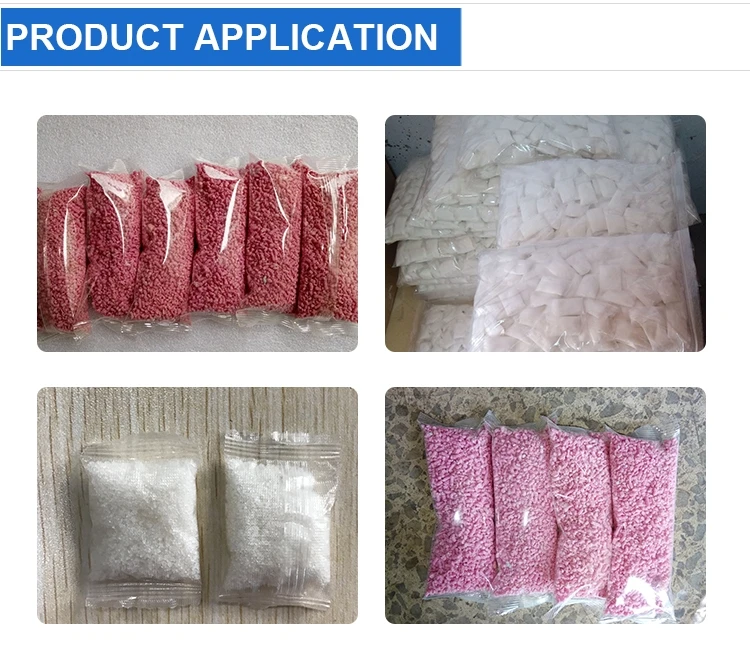

Small full auto feed packaging machine is an automated machine designed to package products efficiently and accurately. It is typically used in industries such as food, pharmaceuticals, cosmetics, and consumer goods. This type of machine is capable of handling the entire packaging process, including feeding the products into the machine, filling them into packaging materials, and sealing the packages.

What are the uses of small full auto feed packaging machine?

Small full auto feed packaging machines are compact in size and suitable for small to medium-scale production. They offer automation, efficiency, and accuracy, reducing labor costs and ensuring consistent packaging quality. These machines are versatile and can be used for a wide range of products, including powders, granules, liquids, and solid items.

Packaging specifications of small full auto feed packaging machine

Small full auto feed packaging machine is suitable for 0-80g, 20-200g, 200-1000g, 1000-3000g per bag. They load feed into bags by pushing at an angle, horizontally or vertically. All can automatically complete measurement, date printing (optional), bag making, filling, sealing, slitting, and counting. For weighing feed packaging, you can choose semi-automatic packaging of 1-10kg and 5-50kg.

Here are some key features and components commonly found in a small full auto feed packaging machine:

Feeding System: The machine is equipped with a feeding system that automatically transports the products from a hopper or conveyor into the packaging machine. This system ensures a continuous and controlled flow of products.

Filling System: The filling system dispenses the correct quantity of products into the packaging materials. It can use various methods such as volumetric filling, auger filling, piston filling, or weigh filling, depending on the nature of the product.

Packaging Material Handling: The machine is designed to handle different types of packaging materials, such as pouches, bags, sachets, or containers. It can accommodate various sizes and shapes of packaging materials.

Sealing Mechanism: The machine includes a sealing mechanism to securely seal the packaging materials after the products are filled. Common sealing methods include heat sealing, ultrasonic sealing, or zip-lock sealing, depending on the packaging material and product requirements.

Control System: A control panel or interface allows operators to set and adjust parameters such as packaging speed, filling quantity, and sealing temperature. It also provides monitoring and diagnostic functions to ensure the machine operates smoothly.

It's important to select a machine that suits your specific product requirements, packaging materials, and production volume. Consulting with packaging machinery suppliers or manufacturers can help you choose the right machine for your needs.