What is full auto feed packaging machine?

Full auto feed packaging machine , also known as a fully automatic feeding packaging machine, is a specialized equipment used for automated packaging of products. This type of machine integrates the processes of product feeding, filling, sealing, and labeling, among others, into a single automated system.

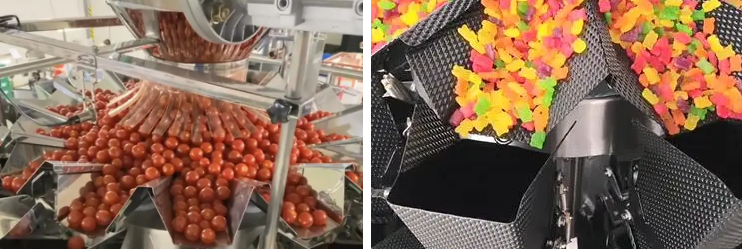

Live Video

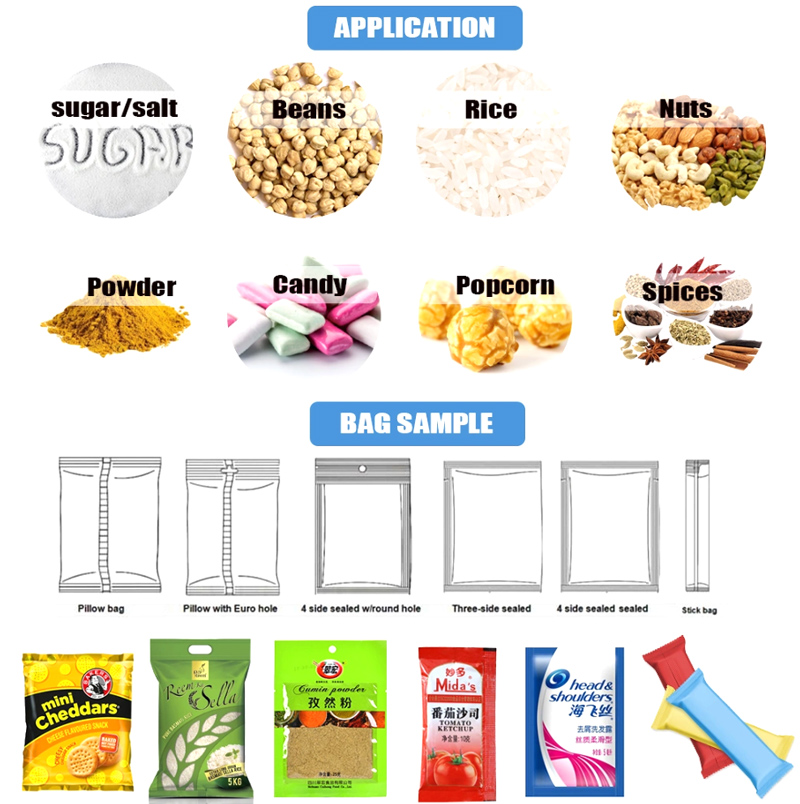

Full auto feed packaging machine of application

Pellet feed packaging: The fully automatic feed packaging machine is suitable for packaging various types of pellet feed, such as bird feed, poultry feed, etc. It can automatically measure and fill pellet feed according to the preset packaging capacity, and seal and label it.

Powdered feed packaging: For fine powdered feed, the fully automatic feed packaging machine can achieve accurate metering and packaging. It can control the fluidity of powdered feed, avoid accumulation and leakage, and maintain the freshness and quality of feed through appropriate sealing methods.

Mixed feed packaging: The fully automatic feed packaging machine is also suitable for packaging mixed feed, that is, mixing feeds of various different ingredients in a certain proportion and packaging them. It can accurately measure and mix different feed ingredients and put the mixed feed into packaging bags or containers.

Special feed packaging: Certain special types of feed, such as grass, fish feed, pet food, etc., can also be packaged by fully automatic feed packaging machines. According to the characteristics and packaging requirements of these special feeds, suitable models and accessories can be selected to complete the packaging process.

How does Full auto feed packaging machine work?

The working principle of the fully automatic feeding packaging machine is that the feed is transported from the storage bin or the conveying system on the production line to the packaging machine. Then, the packaging machine detects the weight of the feed through the weighing sensor to ensure the accurate weight of each bag of feed. Then, according to the preset packaging specifications and requirements, the packaging machine automatically opens the packaging bag and accurately puts the correct weight of feed into the packaging bag. After that, the packaging machine seals the packaging bag and prints information such as production date and batch number. Finally, the packaging machine discharges the completed packaging bag and starts the next packaging cycle at the same time. The whole process realizes automated feed packaging and improves packaging efficiency and accuracy.

Features of full auto feed packaging machine

Keep feed fresh: The fully automatic feed packaging machine can package feed quickly and efficiently, effectively maintain the freshness and nutritional value of feed, and prevent feed from losing nutrition due to long-term exposure.

Accurate packaging: Through precise weighing sensors and control systems, the fully automatic feed packaging machine can ensure that the weight of each bag of feed is accurate.

Extend shelf life: Through appropriate packaging materials and methods, the fully automatic feed packaging machine can extend the shelf life of feed and reduce loss and waste.

Moisture-proof and insect-proof: The fully automatic feed packaging machine can use moisture-proof and insect-proof packaging materials to effectively protect the feed from moisture and insect pests and extend the shelf life of the feed.

Maintain feed quality: The fully automatic feed packaging machine usually uses packaging bags or containers with good sealing properties, and can be equipped with moisture-proof and dust-proof functions to prevent the feed from being contaminated by external factors such as moisture and dust.

Full auto feed packaging machine specifications

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

When selecting a full auto feed packaging machine, consider factors such as the product type, packaging material, packaging size, desired packaging speed, and specific requirements for sealing, labeling, or printing. It is important to choose a machine from a reputable manufacturer that offers reliable performance, after-sales support, and customization options to meet your specific packaging needs.

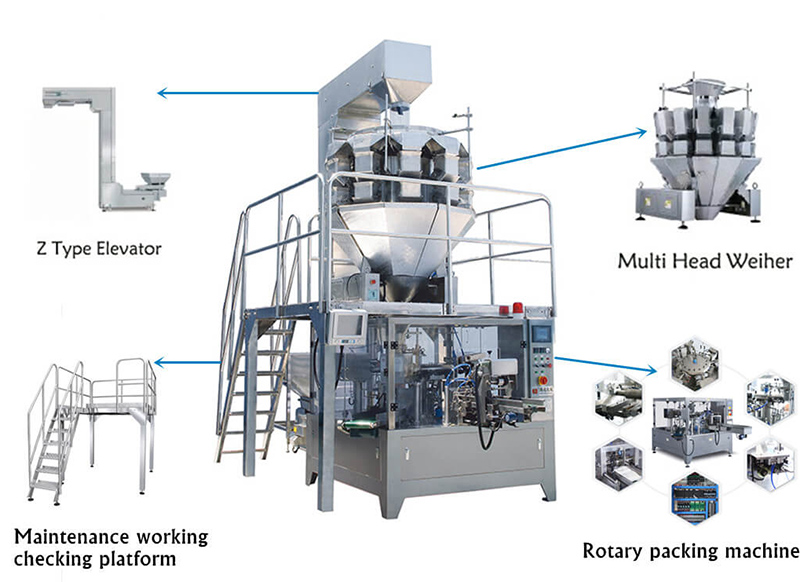

Fully automatic feed packaging machine structure

Fully automatic feed packaging machines usually consist of a feeding system, a metering system, a bag supply system, a sealing system, a conveying system, a control system, a human-machine interface, and a safety system. The feeding system is responsible for conveying the feed to the packaging machine, the metering system ensures accurate weighing, the bag supply system provides bags, the sealing system seals the bags, and the conveying system conveys the bags to the next stage. The control system monitors the entire process, the human-machine interface facilitates operation, and the safety system ensures safe operation. These components work together to complete high-speed and accurate feed packaging, improve production efficiency, and maintain feed quality.

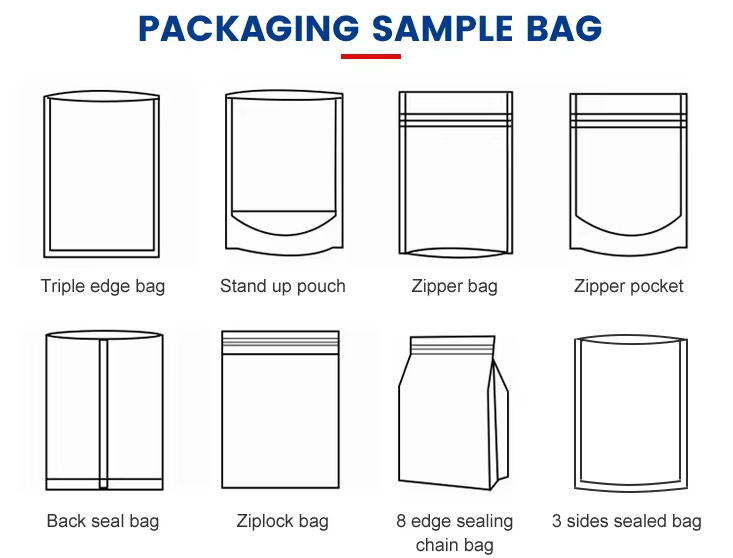

Fully automatic packaging sample bag display

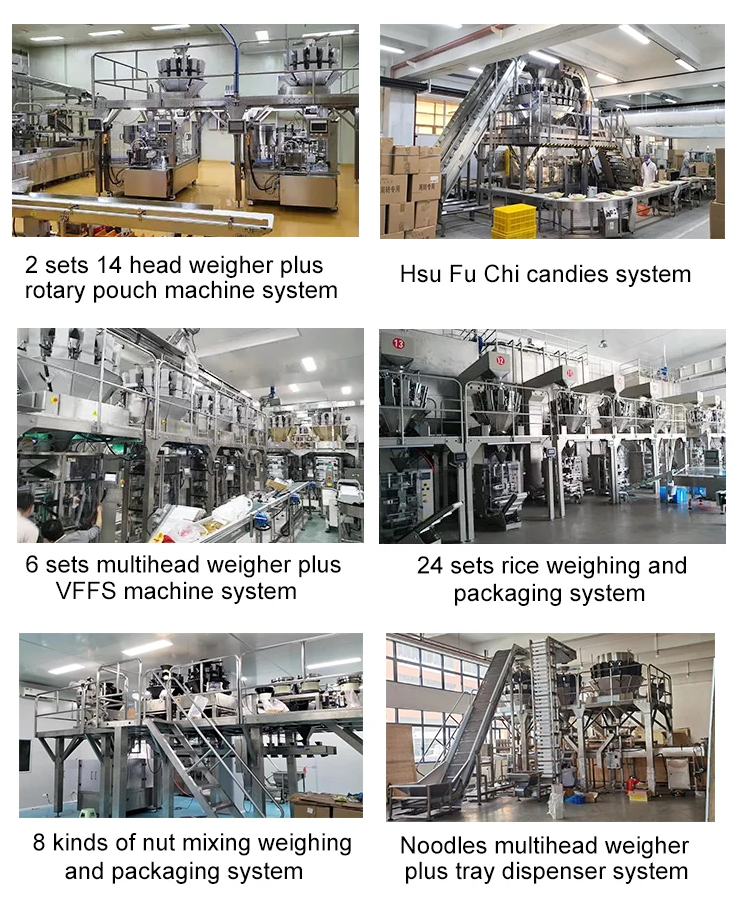

Customer case

| Packaging Case | Packaging Materials | Packing volume | Packing size | Customer feedback |

| Aquafeed Packaging | High-grade aquatic feed, livestock and poultry feed, premix and other powders | 20-50 kg per bag | Bag width 550-600 mm, bag length 900-1060 mm | The full auto feed packaging machine unit in this case has functions such as automatic weighing, bagging, filling, packaging, labeling, heat-sealing inner bags, and folding and sewing bags. It is controlled by a 10.2-inch color touch screen and supports full Chinese display, which is convenient for customers to operate. |

| Rabbit food pellet packaging | Rabbit grain and other pellet feed | 50-320g per bag | Bag width 90-235 mm, bag length 50-320 mm | The model of this Full Auto Feed Packaging Machine is MCGD8-235, with a packaging speed of 25 to 50 bags/minute. The bag width can be automatically adjusted, which is suitable for the packaging needs of various granular materials. |

| Silage Baling | Silage | 65-100 kg per bundle | Bale size is 550 mm in diameter and 520 mm in length | This fully automatic silage baler can pack grass clippings, silage and other materials into round bales. It is suitable for silage storage in animal husbandry, with a packing speed of 30-50 bales/hour. |

![[field:title/]](/uploads/240108/1-24010Q54QTC.png)