Structure of Double Feeding Vertical Packaging System

Tuesday January-23 2024 16:45:35

Double feeding vertical packaging system is a specialized equipment designed to package multiple products simultaneously or increase the packaging speed by utilizing two feeding units. This system is commonly used in industries where there is a need to package different products or achieve higher production rates. This article We will introduce you to the Double feeding vertical packaging system in detail.

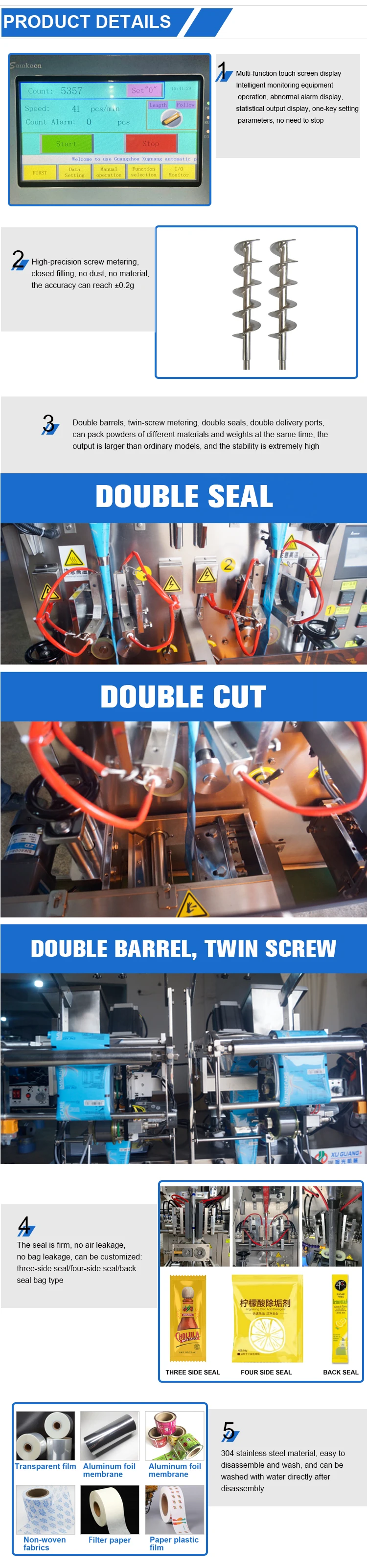

The structure of a double feeding vertical packaging system typically consists of the following components:

Feeding System: The feeding system is responsible for delivering the product to the packaging machine. In a double feeding system, there are two feeding units that can simultaneously feed two different products or feed the same product at a higher speed. This system may include conveyors, hoppers, or vibratory feeders to ensure a continuous and controlled flow of the product.

Weighing System: The weighing system is an integral part of the double feeding vertical packaging system. It includes multiple weighing heads or scales that accurately measure the weight of the product. These weighing heads can operate independently or in synchronization to ensure precise portioning of the product.

Bag Forming System: The bag forming system is responsible for creating the packaging material into a bag shape. It may include a film roll holder, film unwinding mechanism, and bag forming tools. The system can form bags of various sizes depending on the product's packaging requirements.

Filling System: The filling system transfers the measured product from the weighing system into the formed bags. It can use augers, vibratory trays, or other mechanisms to control the flow of the product and ensure accurate filling.

Sealing System: The sealing system seals the filled bags to create a secure and airtight package. It may utilize heat sealing, impulse sealing, or other sealing methods depending on the packaging material and product requirements.

Control System: The control system is the brain of the packaging system. It includes a programmable logic controller (PLC) or a computer-based control panel that manages and coordinates the operations of the feeding, weighing, bag forming, filling, and sealing components. The control system allows for programming different parameters such as bag length, filling weight, and sealing time.

Safety Features: Double feeding vertical packaging systems are equipped with safety features to protect operators and prevent accidents. These may include emergency stop buttons, safety sensors, and guarding mechanisms to ensure safe operation.

The specific design and configuration of the double feeding vertical packaging system may vary depending on the manufacturer and model. It's essential to consult the equipment manufacturer or supplier for detailed specifications and documentation related to the specific system you are interested in.