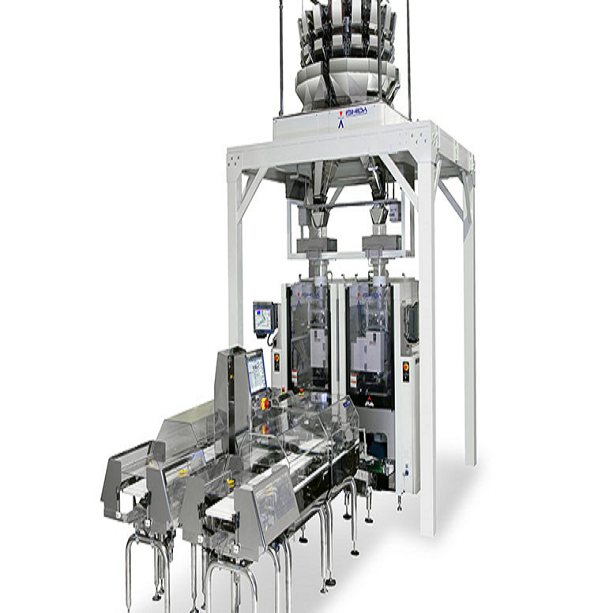

What is a double feeding vertical packaging system?

Double feeding vertical packaging system is a type of packaging machinery that is designed to increase packaging efficiency by incorporating two separate product feeding mechanisms into a single system. It enables simultaneous packaging of two different products or the same product with different specifications, offering higher throughput and versatility.

What are the advantages of double feeding vertical packaging system

The dual-feed vertical packaging system takes advantage of the dual feeding and spreads rapidly in the market. It is suitable for packaging various granules, powders, granule mixtures and other products. It is called one of the ideal packaging solutions chosen by many industries. The following are some advantages of the dual-feed vertical packaging system:

Synchronous work: The dual-feed vertical packaging system can handle two feeding channels at the same time, thereby reducing the time and process of bagging and improving the speed and efficiency of packaging.

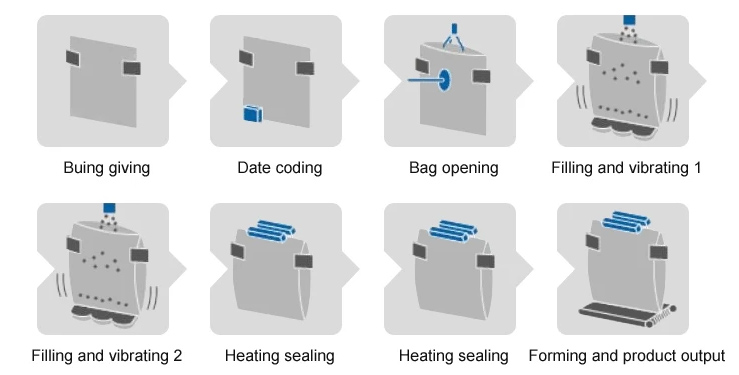

Automated operation: It can realize automatic feeding, bag making, sealing, cutting and other operations to improve production efficiency and consistency.

Adapt to diversified products: The dual-feed vertical packaging system can be used to package a variety of material combinations, suitable for packaging of various products such as food, medicine, cosmetics, etc.

Double production capacity: The dual-head design can bag, seal and cut two products through two independent feeding ports, thereby doubling the production capacity.

How does double feeding vertical packaging system work?

The Double Feeding Vertical Packaging System is a packaging machinery that incorporates two independent product feeding mechanisms into a single machine. It enables simultaneous packaging of two different products or the same product with different specifications. The system operates by loading the products onto separate feeding conveyors, which then deliver the products to the packaging area. The packaging process involves forming packaging materials into bags or pouches, filling them with the products, and sealing them securely. Advanced control systems ensure synchronization between the two feeding mechanisms, allowing for precise coordination and efficient packaging. Operators can adjust parameters such as packaging speed, bag sizes, and sealing parameters to meet specific requirements. The system improves productivity, versatility, and enables manufacturers to handle diverse packaging needs effectively.

Double feeding vertical packaging system specifications

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

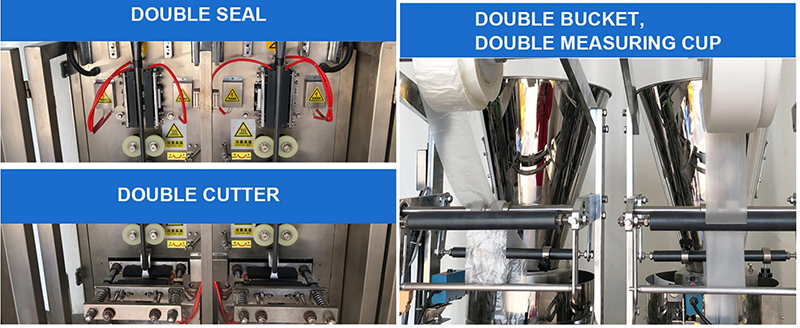

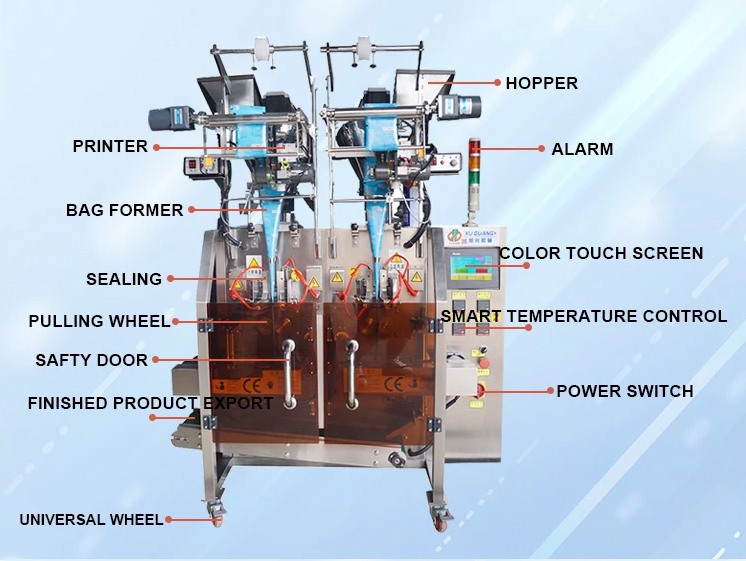

What are the structures of the double-feed vertical packaging system

The structure of the dual-feed vertical packaging system works in coordination to achieve functions such as product metering, packaging and sealing. The following are the structural components of a typical dual-feed vertical packaging system:

Double feeding system: Double feeding is one of the key features of this packaging system. It consists of two independent feeding devices that can supply materials to the packaging machine simultaneously or alternately.

Double feeding packaging machine: The packaging machine is the core component of the double feeding vertical packaging system. It is usually composed of a vertical packaging machine with automated material feeding, metering, packaging and sealing functions.

Double feeding conveying system: The conveying system is used to convey materials from the double feeding system to the packaging machine to ensure continuous supply and smooth delivery of materials.

Double feeding control system: The double feeding vertical packaging system is usually equipped with an advanced automatic control system. The system can monitor and adjust the operating parameters of the packaging machine to ensure stable packaging quality and efficient production.

Auxiliary equipment: In addition to the above main components, the double feeding vertical packaging system may also include other auxiliary equipment, such as material storage bins, dust removal systems, compressed air systems, etc., to provide a complete packaging solution.

What are the applications of double feeding vertical packaging system?

Whether producing the same product or two products, the dual-feed vertical packaging system has the advantages of improving production efficiency, reducing downtime and fast material change operations. The following is a description of the application in different scenarios:

Producing the same product

Food industry: In the food industry, the dual-feed vertical packaging system can be used to package the same type of food, such as potato chips of the same flavor. The system can extract the same food from two different silos at the same time to improve packaging speed and production efficiency.

Producing two different products

(1) Snack industry: In the snack industry, the dual-feed vertical packaging system can handle two different flavors of potato chips at the same time, such as original flavor and tomato flavor. The system can extract different flavors of products from different silos to ensure that two flavors of potato chips can be packaged at the same time.

(2) Cosmetics industry: In the cosmetics industry, the dual-feed vertical packaging system can be used to package two different colors of lipstick at the same time to ensure that different colors of products can be packaged on the production line at the same time.

Customer case

| Customer Background | Customer Needs and Problems | Solutions | Customer Feedback |

| A large candy manufacturer mainly produces candy products of various specifications, including hard candy, soft candy and chocolate candy. | An efficient and accurate packaging system is required to adapt to the packaging of candies of different specifications; the traditional single-channel packaging system is inefficient and cannot meet the peak production needs. | The double-channel vertical packaging system (Double Feeding Vertical Packaging System) is used, equipped with a multi-head weighing machine and automatic bag making function, to achieve a fully automated process from feeding, weighing, filling to packaging. | The packaging speed is increased to 60 bags/minute, and the efficiency is increased by 50%; the weighing accuracy reaches ±0.2g, which significantly reduces material waste; the system supports a variety of packaging specifications and flexibly adapts to different product needs |

| A company specializing in nut processing, its products include peanuts, almonds, cashews, etc. | Nut particles are irregular, and traditional packaging equipment is prone to jamming, affecting production efficiency; a high-precision weighing system is required to ensure the consistent weight of each bag of product. | The dual-channel vertical packaging system is introduced, equipped with anti-jamming design and high-speed weighing module to ensure smooth transportation and accurate weighing of nut particles. | The packaging speed is stable at 50 packs/minute, and the material jamming problem is completely solved; the weighing accuracy is controlled at ±0.5g, and customer satisfaction is greatly improved; the system supports multi-language operation interface, which is convenient for employees to use |

| A pet food manufacturer, mainly producing granular foods such as dog food and cat food. | Pet food particles are large, and traditional packaging equipment fills unevenly, affecting the appearance of the product; a high-capacity packaging system is required to meet the growing market demand. | A dual-channel vertical packaging system is used, equipped with a large-capacity hopper and a high-speed filling device to ensure uniform filling and efficient packaging of pet food. | The packaging speed reaches 70 packs/minute, and the production capacity is increased by 40%; the filling uniformity is significantly improved, and the product appearance is more beautiful; the system supports a variety of packaging materials to meet different market needs |

What are the differences between a dual-feed vertical packaging system and a single-feed vertical packaging system?

Feeding method: The dual-feed vertical packaging system has two independent feed outlets, which can be fed simultaneously or alternately. This means that it can handle two different materials or pack different specifications of the same material at the same time. In contrast, the single-feed vertical packaging system has only one feed outlet and can only handle one material.

Production efficiency: Since the dual-feed vertical packaging system has multiple feed outlets, it can achieve higher production efficiency. Simultaneous or alternating feeding can reduce downtime and increase packaging speed and production capacity. The single-feed vertical packaging system has relatively low production efficiency under the same conditions.

Application scenario: The dual-feed vertical packaging system is suitable for application scenarios where two different materials need to be processed simultaneously or materials of different specifications need to be packaged simultaneously. It can flexibly adapt to diverse production needs and is suitable for production lines that require efficient packaging. The single-feed vertical packaging system is more suitable for scenarios where only a single material or a single specification of packaging needs to be processed.

What is the double feeding vertical packaging system price?

The price of a dual-feed vertical packaging system varies depending on factors such as brand, specifications, functions, performance, and market competition. Generally speaking, the price of a dual-feed vertical packaging system is usually higher than that of a single-feed system, ranging from $800.00 to $13,600.00, because it has the ability to handle two different products at the same time, providing higher production efficiency and flexibility. If you need it, you can directly contact our back-end, and we will provide detailed requirements to obtain accurate pricing information.

Why choose us as your top double feeding vertical packaging system supplier?

Xiangdahan is a company specializing in packaging equipment manufacturing. They provide high-quality double feeding vertical packaging systems. As an experienced manufacturer, Xinxiang Dahan is committed to providing customers with customized solutions to meet the packaging needs of different industries and products. Their double feeding vertical packaging system features advanced technology and innovative design, capable of handling two different products simultaneously and achieving efficient and accurate packaging. Xinxiang Dahan focuses on product quality and reliability, using high-quality materials and advanced manufacturing processes to ensure the stability and durability of the equipment. In addition, they also provide complete after-sales service to ensure that customers receive comprehensive support and assistance during the purchase and use process. Whether it is food, cosmetics, medicine or other industries, Xinxiang Dahan's double feeding vertical packaging system can provide customers with efficient and reliable packaging solutions.