What is chocolate packing machine?

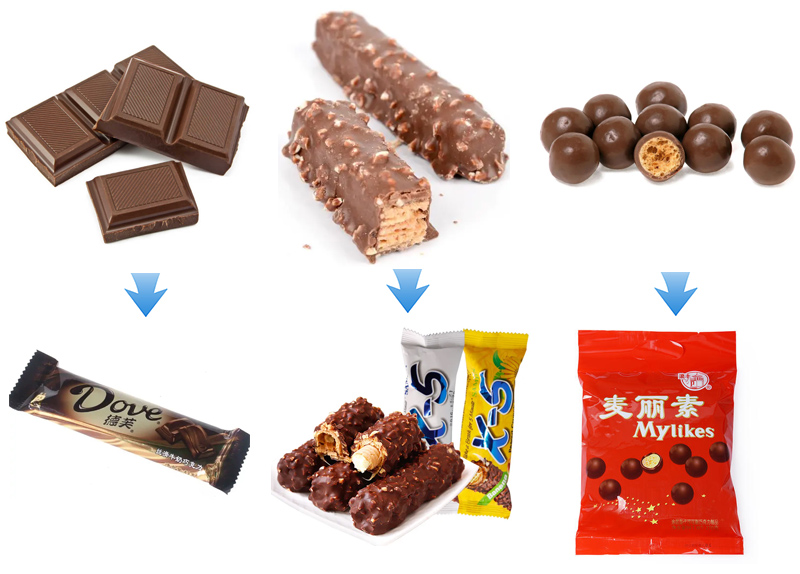

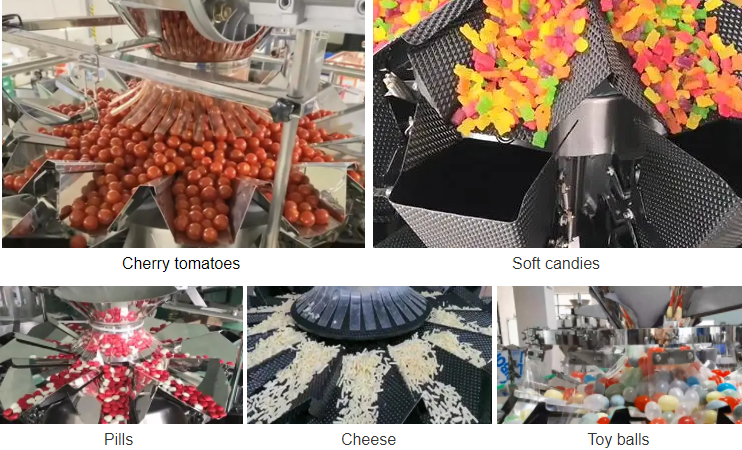

Chocolate packing machine is a type of automatic packaging machine specifically designed for packaging chocolate products. These machines offer efficient and precise packaging solutions to meet the demands of the chocolate industry. The machines are versatile and can handle a wide range of chocolate products, including solid chocolate bars, chocolate chips, chocolate powder, and more.

Chocolate packing machine plays a crucial role in the efficient and hygienic packaging of chocolates. It offers automation, flexibility, accuracy, and high production efficiency, contributing to the overall quality and presentation of chocolate products.

Live Video

What are the applications of chocolate packing machine?

Chocolate packing machines are used in the confectionery industry to package a variety of chocolate products produced by packaging companies, including chocolate bars, chocolate beans, chocolate blocks, spherical chocolates, filled chocolates, handmade chocolates and high-end custom chocolates. In addition to chocolate, chocolate packing machines are also used in retail packaging, gift packaging and food service industries. These machines simplify the packaging process, ensure product quality, enhance display effects, and promote efficient distribution.

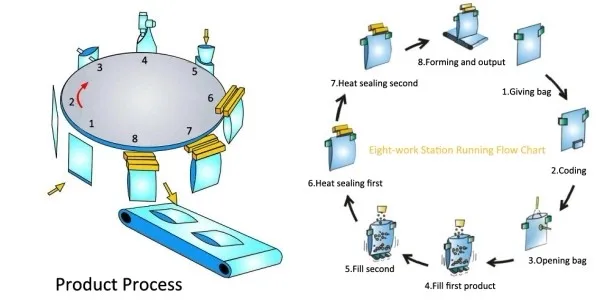

How does chocolate packing machine work?

A chocolate packing machine is designed to automate the packaging process for chocolates and similar confectionery products. It typically operates by feeding the chocolates onto a conveyor belt or feeding system, which then moves them through various packaging stages. These stages may include aligning the chocolates, wrapping them in individual packaging materials such as foil or plastic, sealing the packages, and labeling or coding them. The machine incorporates controls and sensors to ensure precise and efficient packaging, while also providing options for customization, speed adjustment, and quality assurance. The goal of a chocolate packing machine is to streamline the packaging process, improve productivity, and maintain the integrity and appearance of the chocolates during packaging.

What are the advantages of Chocolate Packing Machine?

As an indispensable equipment in the chocolate production line, chocolate packaging machine uses its own advantages to help enterprises improve production efficiency, ensure packaging quality to meet the special needs of different customers, thereby enhancing competitiveness and market performance. Its advantages include but are not limited to the following points

Automation:Chocolate packing machines are fully automated, requiring minimal manual intervention. This results in increased production efficiency and consistency in packaging.

Speed and Efficiency: The machines operate at high speeds, enabling manufacturers to meet large production volumes and fulfill orders promptly.

Versatility: Chocolate packing machines can accommodate a variety of chocolate products, including different shapes, sizes, and wrapping materials.

Hygiene and Sanitation: The machines are designed with hygienic and sanitary features to prevent contamination and maintain product quality.

Flexibility: The machines can be customized to meet specific packaging requirements, such as different types of wrapping materials, labeling, and product feeding systems.

Chocolate packing machine specifications

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

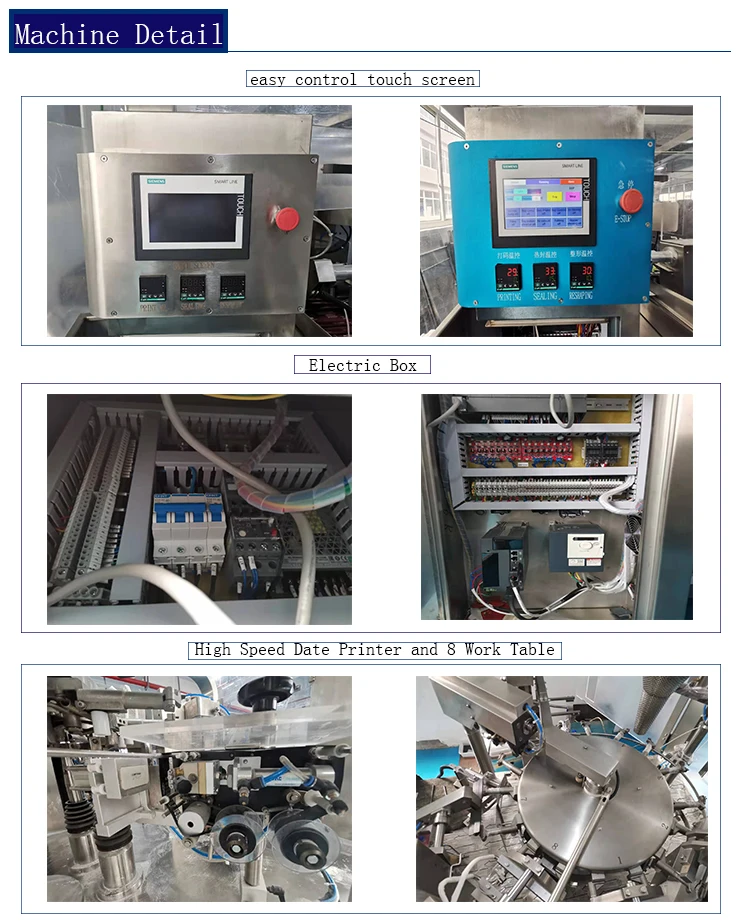

Structure of Chocolate Packing Machine

The structure of a chocolate packing machine typically consists of a solid framework that houses the essential components required for automated chocolate packaging. These components include a feeding system, conveyor belts, wrapping stations, sealing units, and control systems. The feeding system ensures a steady flow of chocolates into the packaging machine. The conveyor belts transport the chocolates through different packaging stages, such as aligning, wrapping, and sealing. The wrapping stations are equipped with mechanisms to enclose the chocolates in packaging materials, such as foil or plastic. The sealing units securely seal the packages to maintain product freshness. The control systems monitor and regulate the machine's operation, allowing for customization, speed adjustment, and quality control.

Chocolate Packing Machine: FAQ Guide

What is the best packaging for chocolate?

When packing chocolate, you can choose metal foil packaging with strong barrier properties, paper box packaging with beautiful and high-end appearance, plastic film packaging with transparent display, and resealable packaging for easy storage.

How to choose a chocolate packaging machine?

When choosing a chocolate packaging machine, you need to carefully consider the type of chocolate (such as blocks, rows, balls, etc.), which determines the feeding and packaging methods. Clarify the packaging requirements, including whether nitrogen filling preservation, shockproof and other functions are required. Select the machine speed and degree of automation according to the packaging volume. Confirm the packaging bag materials compatible with the machine (such as OPP, PE, composite film) and the required sealing method. Finally, verify the range of packaging sizes that the machine can handle. Consider the above factors and choose the packaging equipment that best meets your production needs.

Chocolate Packing Machine Customer case

| Customer Background | Solutions | Customer Feedback |

| A chocolate production company mainly produces bar-shaped chocolate and needs efficient packaging to meet market demand. | SMZ-420 pillow-type Chocolate Packing Machine is used, which is specially designed for bar-shaped objects and suitable for chocolate bar packaging. | The packaging speed reaches 1/2 second, which greatly improves production efficiency; the packaging effect is exquisite and the sealing is good, which prolongs the shelf life of chocolate; the equipment runs stably, reduces manual intervention and reduces costs. |

| A high-end handmade chocolate brand pays attention to the exquisiteness and hygiene of packaging. | KT-250 Chocolate Packing Machine is selected, which is made of 304 stainless steel and meets food-grade hygiene standards. | The equipment has dual frequency conversion control, and the bag length is set and cut immediately, reducing the waste of packaging film; high-sensitivity photoelectric eye color tracking ensures accurate sealing and cutting positions and consistent packaging appearance; customers can choose to use an inflator according to their needs to extend the shelf life of chocolate |

| A New Zealand dessert chain brand needs to design a gift-style packaging box for chocolate. | The packaging box uses food-grade laminating technology and is equipped with an automated Chocolate Packing Machine. | The packaging box adopts an easy-tear design to improve the user experience; used in conjunction with the packaging machine, it realizes a fully automated process from packaging to boxing; customers are very satisfied with the exquisiteness of the packaging and production efficiency, and the order is quickly placed |

What is the chocolate packing machine price?

The price of a chocolate packing machine can vary depending on several factors, including the machine's capacity, features, brand, and the supplier or manufacturer. Additionally, market conditions and geographical location can also influence the pricing.

When considering the price of a chocolate packing machine, it's important to evaluate not only the upfront cost but also the long-term benefits, such as efficiency, reliability, and after-sales support. It's recommended to compare different options, request multiple quotes, and consider the overall value and return on investment provided by the machine.

Chocolate packing machine manufacturers in China

Xinxiang Dahan is a professional chocolate packging machine manufacturer. They provide high-quality, reliable chocolate packaging machines to cater to chocolate manufacturing companies of different sizes and needs. Xinxiang Dahan's chocolate packaging machines feature advanced technology and innovative designs, enabling efficient and precise packaging. They focus on product quality and reliability, using high-quality materials and advanced manufacturing processes to ensure the stability and durability of their equipment. In addition, Xinxiang Dahan also provides complete after-sales services to provide customers with technical support and maintenance guarantees. Whether it is a small chocolate manufacturer or a large production enterprise, Xinxiang Dahan's chocolate packaging machines can provide efficient and reliable packaging solutions to help customers improve production efficiency and product quality.