What is a standard vertical weighing and packaging system?

Standard vertical weighing and packaging system is a type of automated packaging machine commonly used in various industries to accurately weigh and package products into pre-formed bags or pouches. This system is designed to handle a wide range of products, including food, pharmaceuticals, hardware, and other consumer goods.

Types of standard vertical weighing and packaging system

The standard vertical weighing and packaging system sold by Xinxiang Dahan has absolutely good quality and good ex-factory price. Our granule packaging machine is suitable for various granular materials, such as tea, potato chips, snacks, chocolate, rice, popcorn, candy, sugar, etc. We have a variety of granule packaging machines to choose from. The fully automatic granule packaging machine has high efficiency, stable performance and easy operation. Semi-automatic granule filling machines and manual granule packaging equipment are available at affordable prices. In addition, you can also choose a small particle vertical packaging machine or a high-efficiency multi-head scale packaging machine according to the materials to be packaged. In addition, we have different bag types (back sealing and three-side sealing), packaging speed, voltage, and power to choose from, so we can provide the most suitable packaging machine according to your actual situation. Leave us a message and we will send you the best price.

How does standard vertical weighing and packaging system work?

The standard vertical weighing and packaging system works by automating the process of weighing, filling, and sealing products in bags or pouches. The product to be packaged is stored in a hopper, which feeds it into the weighing system. The weighing mechanism accurately measures the product's weight using load cells or other weighing sensors. Once the desired weight is achieved, the system releases the product into a bag formed from a roll of packaging material. The bag is then sealed using heat or mechanical sealing mechanisms. The entire process is controlled by a programmable logic controller (PLC) or a computerized control panel, allowing operators to set parameters and monitor the packaging process. This system offers high-speed and precise weighing and packaging, improving productivity and maintaining consistent packaging quality.

Live video

Features of standard vertical weighing and packaging system

Accuracy: Standard vertical weighing and packaging systems are designed to provide accurate weighing and packaging results. This is achieved through the use of high-quality load cells and sensors, as well as advanced control algorithms.

Speed: Standard vertical weighing and packaging systems are designed to operate at high speeds, allowing for increased productivity. This is achieved through the use of high-speed filling and sealing mechanisms, as well as efficient product handling and distribution systems.

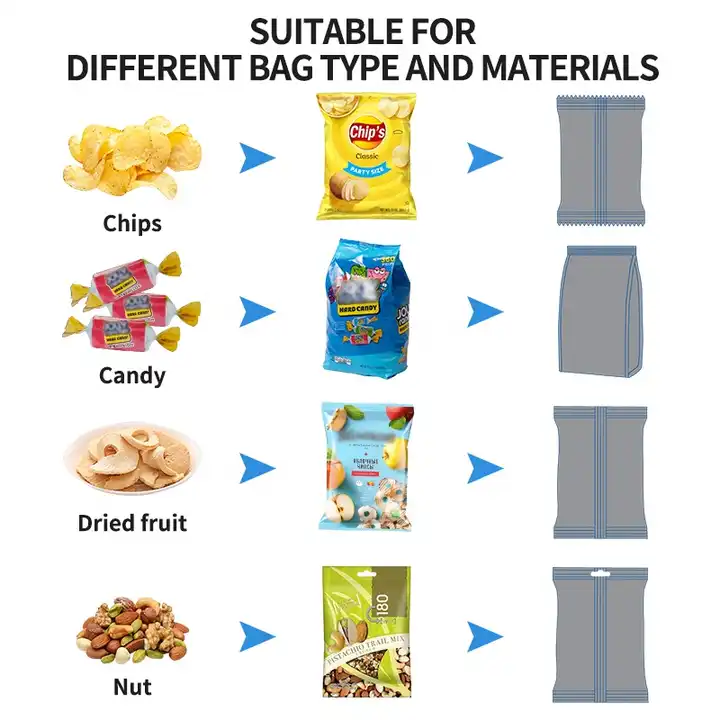

Versatility: Standard vertical weighing and packaging systems are designed to be versatile, allowing for the packaging of a wide variety of products. This is achieved through the use of adjustable filling and sealing mechanisms, as well as the ability to handle a variety of packaging materials.

Reliability: Standard vertical weighing and packaging systems are designed to be reliable, ensuring consistent operation and minimal downtime. This is achieved through the use of high-quality components and construction, as well as rigorous testing and quality control procedures.

Ease of Use: Standard vertical weighing and packaging systems are designed to be easy to use, allowing for quick and efficient operation. This is achieved through the use of intuitive controls and operator interfaces, as well as clear and concise documentation.

Sanitary Design: Standard vertical weighing and packaging systems are designed with a focus on sanitary construction, ensuring that they meet the highest standards of hygiene and cleanliness. This is achieved through the use of stainless steel and other food-grade materials, as well as the implementation of washdown procedures and protocols.

Standard vertical weighing and packaging system specifications

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

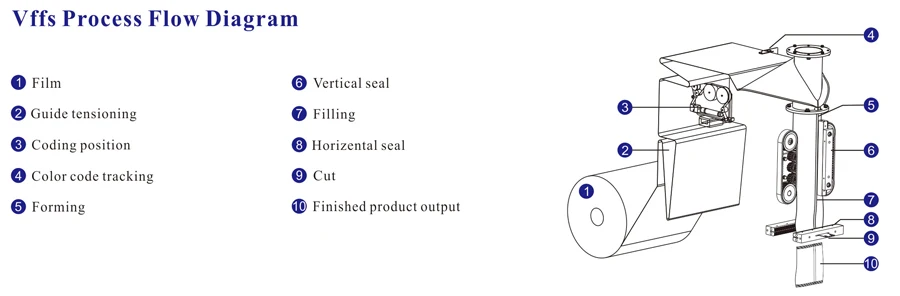

Structure of standard vertical weighing and packaging system

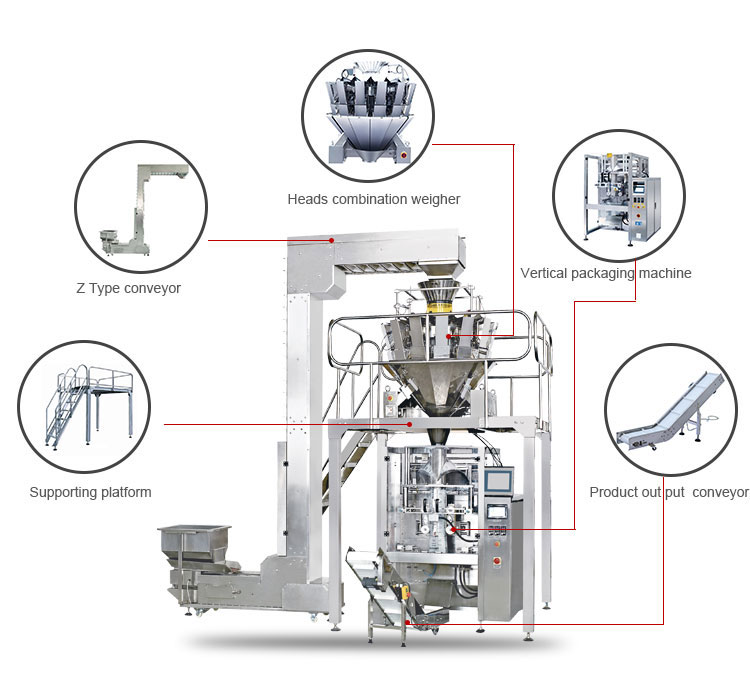

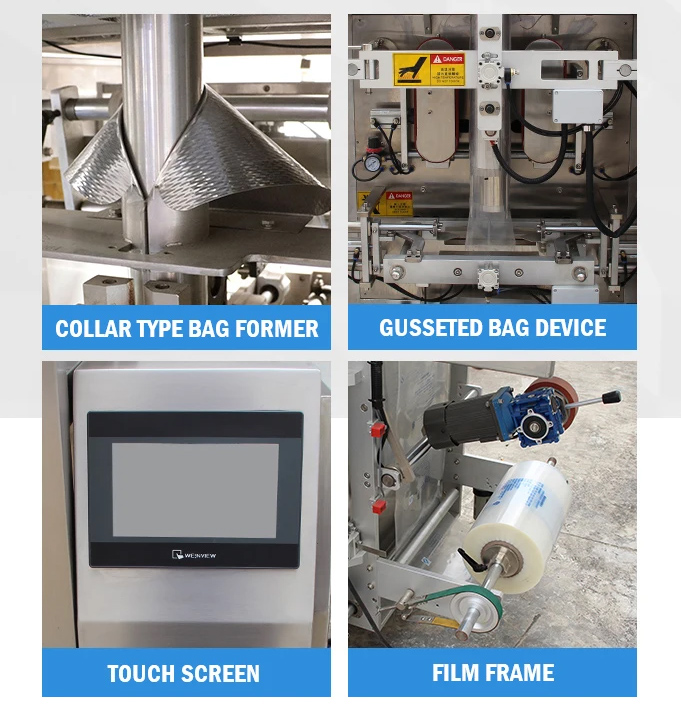

Vertical Form-Fill-Seal (VFFS) Machine: This machine is the core component of the system. It forms a vertical bag from a roll of packaging film, fills the bag with the desired product, and seals it. The VFFS machine is equipped with weighing and dosing mechanisms to ensure accurate product measurement and filling.

Weighing System: The weighing system is integrated into the VFFS machine and is responsible for accurately measuring the weight of the product to be packaged. It typically uses load cells or other weighing mechanisms to achieve precise weight measurements.

Product Feeding System: The product feeding system is designed to deliver the product to the weighing system. It can utilize various methods such as gravity feeding, auger feeding, or vibratory feeding, depending on the characteristics of the product being packaged.

Control System: The control system manages and coordinates the operation of the entire weighing and packaging system. It controls the filling process, monitors the weight measurements, and adjusts the packaging parameters as needed. The control system also interfaces with other peripheral equipment, such as printers or labeling machines, for additional functionalities.

Conveyor System: A conveyor system is often used to transport the packaged products from the VFFS machine to the next stage of the packaging process, such as a checkweigher or a cartoning machine. The conveyor system ensures a smooth and continuous flow of packaged products.

Detailed components of standard vertical weighing and packaging system

What are the applications of standard vertical weighing and packaging system?

Standard vertical weighing and packaging systems can be used to package a variety of products, covering many different industries. Here are some common product types:

Dry food: including nuts, puffed food, candy, chocolate, shortbread, crisps, oatmeal, coffee beans, tea, etc.

Granules and granular items: such as grains, seeds, beans, raisins, cat litter, feed, etc.

Powdered items: such as flour, mixed spices, milk powder, protein powder, coffee powder, condiments, washing powder, etc.

Liquid and semi-liquid: such as juices, salad dressings, sauces, oils, cosmetics, detergents, liquid fertilizers, etc.

Customer case

| Packaging Case | Application Scenario | Solution | Customer feedback |

| The customer is a large food processing factory that mainly produces various types of snack foods, such as potato chips, nuts, etc. The production volume is huge, and the packaging efficiency and precision requirements are very high. | Various types of snack foods need to be weighed and packaged at high speed and with high accuracy. | The customer used multiple high-speed vertical weighing and packaging systems, equipped with multi-head combination scales, to achieve high-speed and accurate weighing; the packaging machine is controlled by a servo motor to ensure the quality of the forming and sealing of the packaging bag; it is equipped with an automatic detection system that can automatically remove products that do not meet the weight requirements. | The vertical weighing and packaging system greatly improves packaging efficiency and reduces labor costs; the high weighing accuracy ensures product consistency; the high degree of automation reduces human errors. |

| The client is an agricultural cooperative that mainly grows and sells various agricultural products, such as rice, grains, etc. | Agricultural products need to be packaged in quantitative quantities for easy sale and transportation. | The customer adopted several economical vertical weighing and packaging systems equipped with linear scales to meet the needs of agricultural product packaging; the packaging machines have a simple structure, are easy to operate and maintain; and the packaging parameters can be adjusted according to the characteristics of different agricultural products. | It improves the packaging efficiency of agricultural products and reduces packaging costs; it has high packaging accuracy and ensures the weight consistency of agricultural products; it is simple to operate and convenient for farmers to use. |

| The customer is a chemical company that produces granular chemical products. | Chemical products need to be accurately weighed and packaged to ensure the accuracy of the products before leaving the factory. | The customer uses a corrosion-resistant vertical weighing and packaging system equipped with high-precision weighing equipment; it has good sealing to prevent chemical product dust from leaking out;The packaging machine control system can record the weight data of each package of products to facilitate quality traceability. | The vertical weighing and packaging system ensures the accuracy and safety of chemical product packaging; the anti-corrosion design extends the service life of the equipment; and the data recording function facilitates product quality management. |

Packing material

Polyester/aluminizing/Polyethylene, polypropylene/polyethylene aluminum foil/Polyethylene, nylon/Enhanced polyethylene, tea-leaf filtering paper, paper/Polyethylene, etc.

What is the standard vertical weighing and packaging system price?

The price of a standard vertical weighing and packaging system can vary depending on several factors, including the system's specifications, brand, features, and additional options. Additionally, market conditions and geographical location can also influence the pricing.

In general, standard vertical weighing and packaging system price can range from a few thousand dollars to tens of thousands of dollars.

Standard vertical weighing and packaging system manufacturers China

Xinxiang Dahan is a manufacturer specializing in the production of standard vertical weighing and packaging systems. As one of China's leading suppliers of automated packaging equipment, Xinxiang Dahan has extensive experience and expertise in this field.

Xinxiang Dahan's standard vertical weighing and packaging system adopts advanced technology and innovative design, aiming to improve production efficiency and packaging quality. Their products cover multiple industries, including food, cosmetics, medicine, daily consumer goods, etc.

As a manufacturer, Xinxiang Dahan is committed to providing customers with customized solutions to meet different product and packaging requirements. Their systems are flexible and scalable to accommodate varying sizes and capacity needs.