Food Particles for Multifunctional Fully Automatic Packaging Machine

Food Particles for Multifunctional Fully Automatic Packaging Machine for food particles can perform continuous packaging at high speed to improve production efficiency. It is suitable for various food particles such as nuts, candies, puffed foods, dried fruits, beans, etc.

What are the advantages of the multifunctional fully automatic packaging machine for food particles?

-Fully automatic packaging equipment can complete the packaging process independently and reduce labor costs.

-Accurate measurement, high efficiency, and no broken materials.

-Adopt imported PLC computer control system, color touch screen, easy to operate.

-Adopt imported servo film transport system and marking sensor, accurate positioning, perfect packaging.

-It has a variety of automatic alarm protection functions to minimize losses.

-Various bag making forms, including pillow bags, folded corner bags, hanging hole bags, one-piece bags, etc.

Main features

-Vibration cutting, multi-channel vibration under homogeneous materials, stable material turning, no damage.

High-precision PID control for temperature control, excellent heat sealing stability, to ensure the sealing quality of different materials.

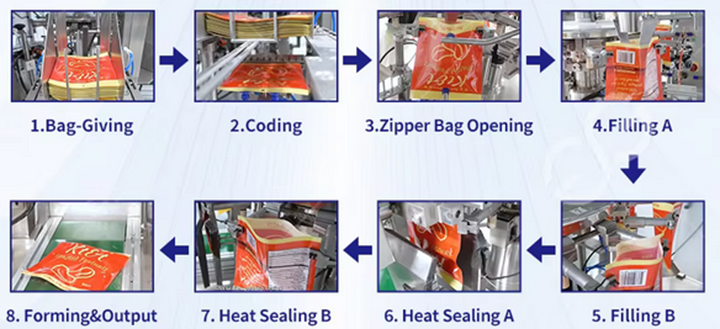

How does the multifunctional fully automatic packaging machine for food particles work?

-Feeding system: The feeding system of the packaging machine is responsible for feeding the food particles to be packaged into the packaging work area.

-Packing bag or container feeding system: A feeding system used to provide packaging bags or containers.

-Measuring system: The metering system is used to accurately measure the filling amount or weight of food particles.

-Packing work area: The packaging work area is the processing area of food particles.

-Sealing and sealing device: A device used to seal and seal the packaging bag or container. This can be a heat sealing device, a pressure sealing device, a sealing clamp or other applicable sealing methods.

-Cutting device: The cutting device is used to cut the filled packaging bag or container into individual packaging units.

-Control system: The multifunctional fully automatic packaging machine for food particles is equipped with an advanced control system for monitoring and controlling the entire packaging process.

-Conveying system: The conveying system is used to output the packaged food particle packaging units to the next stage of processing or packaging line.

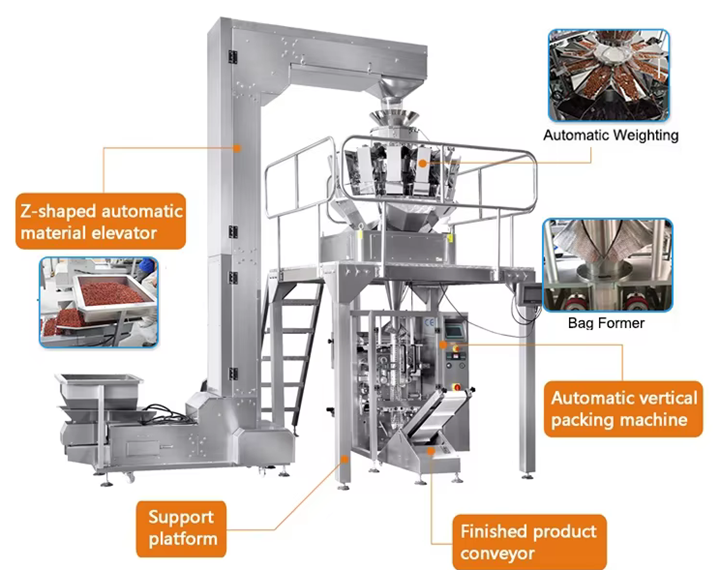

Structure of Multifunctional Fully Automatic Packaging Machine for Food Pellets

-Feeding System: The feeding system of the packaging machine is responsible for feeding the food granules to be packaged into the packaging work area.

-Packing bag or container feeding system: A feeding system for providing packaging bags or containers.

-Measuring system: The metering system is used to accurately measure the filling amount or weight of food granules.

-Packing work area: The packaging work area is the processing area for food granules.

-Sealing and sealing device: A device for sealing and sealing the packaging bag or container. This can be a heat sealing device, a pressure sealing device, a sealing clamp or other applicable sealing methods.

-Cutting device: The cutting device is used to cut the filled packaging bag or container into individual packaging units.

-Control system: The multifunctional fully automatic packaging machine for food granules is equipped with an advanced control system for monitoring and controlling the entire packaging process.

-Conveying system: The conveying system is used to output the packaged food granule packaging units to the next stage of processing or packaging line.

Application scope of food granule multifunctional automatic packaging machine

The food granule multifunctional automatic packaging machine has a wide range of applications and can be used to package various food granules, including grains such as rice, wheat, corn, oilseeds such as peanuts, sunflower seeds, beans such as soybeans, mung beans, dried fruits such as walnuts, almonds, puffed foods such as puffed rice, French fries, and other foods such as candy, pet food, etc. This packaging machine can efficiently handle different types of food granules, improve production efficiency and ensure packaging quality, and is suitable for diversified food production needs.

How to choose the right multifunctional fully automatic packaging machine for food particles?

* According to the type of food particles: Different types of food particles have different shapes and sizes, so you need to choose the right type of packaging machine.

* Packaging speed: You need to choose the right packaging speed according to your production needs.

* Packaging accuracy: You need to choose the right packaging accuracy according to your product quality requirements.

* Packaging function: You need to choose the right packaging function according to your needs, such as whether you need to print the date, whether you need to detect the product weight, etc.

Customer

Monday July-15 2024 14:30:36