What is full auto vertical grain packing machine?

Full auto vertical grain packing machine is a type of packaging machinery specifically designed to package grains vertically. It is an automated system that performs various operations, such as weighing, filling, sealing, and labeling, to package grains efficiently and accurately.

Full auto vertical grain packing machines are commonly used in the food industry, particularly for packaging various types of grains, such as rice, wheat, corn, barley, oats, and pulses. They help improve packaging efficiency, reduce labor costs, ensure product consistency, and maintain hygiene standards in the packaging process.

What are the applications of full auto vertical grain packing machine?

The full auto vertical grain packing machine is widely used in various industries for efficiently packaging granular products. Its key applications include:

Food Industry: Ideal for packing grains like rice, wheat, pulses, corn, beans, and seeds. It's also used for snacks, sugar, salt, and coffee beans.

Agricultural Sector: Common for packing fertilizers, animal feed, and other granular agricultural products.

Chemical Industry: Suitable for packing granular chemicals, plastic pellets, and other non-food granules.

Pharmaceutical Industry: Used for packing medicinal granules, tablets, or coated pills.

Hardware Industry: Effective for packaging screws, nuts, bolts, and other small hardware components.

Live video

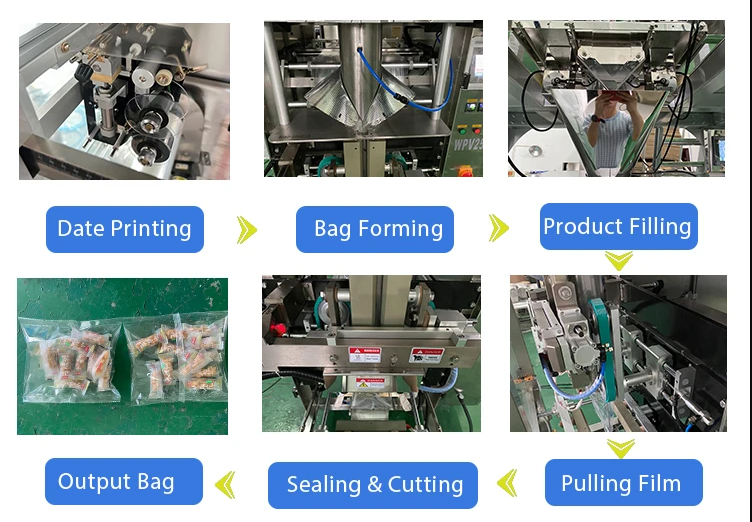

How does full auto vertical grain packing machine works?

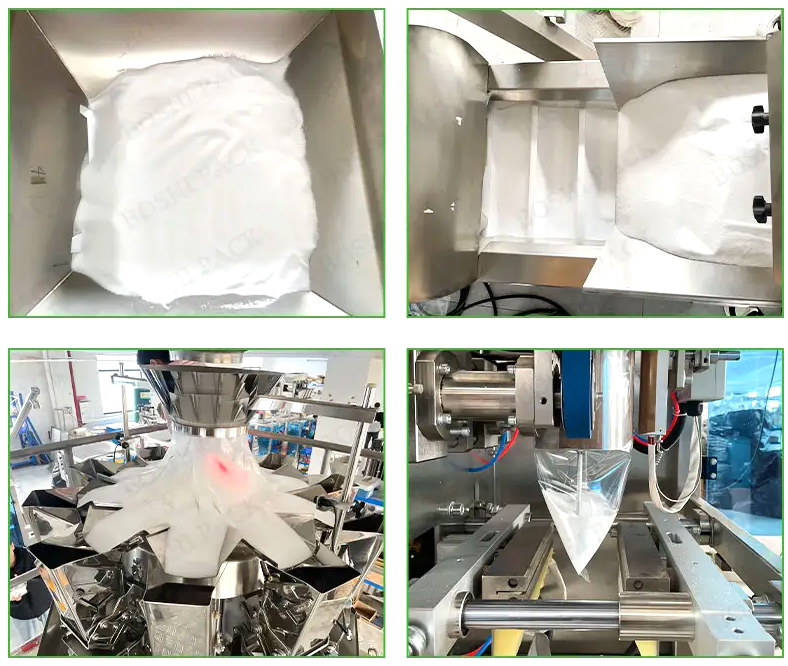

A full auto vertical grain packing machine is an automated system used to package grains efficiently. It works by weighing and dosing the grains, filling them into packaging material, sealing the bags or pouches, and optionally applying labels or printing information. The machine is controlled by a programmable logic controller or a computerized panel, and it typically includes a conveyor system for continuous operation. Overall, it streamlines the packaging process, improves efficiency, and ensures consistent and accurate grain packaging.

Features of full auto vertical grain packing machine

1. High Efficiency: The automated nature of the machine enables high-speed packaging, increasing productivity and reducing labor costs.

2. Consistent Packaging: The machine ensures consistent filling weights and accurate sealing, resulting in uniform and high-quality packaged products.

3. Reduced Labor Requirements: The automation of the packaging process minimizes the need for manual labor, reducing operational costs.

4. Improved Product Quality: The gentle and precise filling and sealing processes help maintain the quality and integrity of the grain products.

5. Reduced Product Loss: The automated system minimizes product spillage and wastage, leading to cost savings.

6. Ease of Operation: The user-friendly control panel and intuitive interface make the machine easy to operate, even for non-technical personnel.

Full auto vertical grain packing machine specifications

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

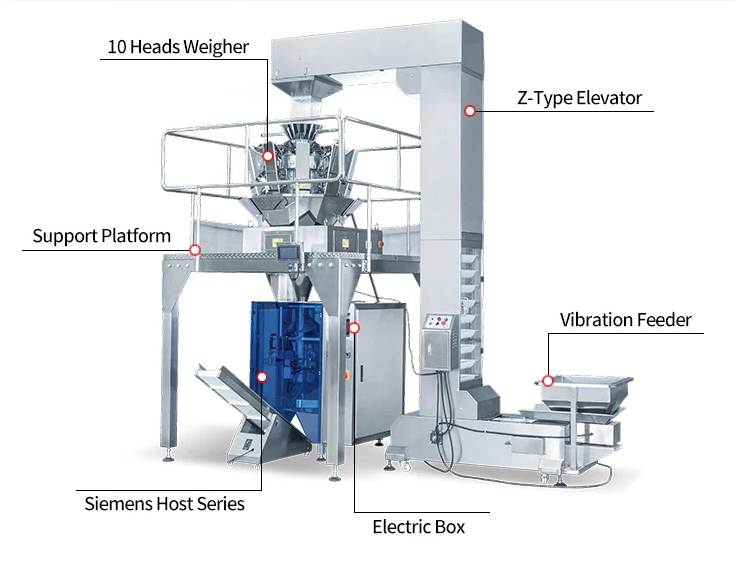

Structure of full auto vertical grain packing machine

1. Frame and Structure: The machine is built with a sturdy frame and structure, ensuring stability and durability during high-speed operations.

2. Bag Feeding Mechanism: The machine incorporates an automatic bag feeder that dispenses pre-made bags into the packaging process.

3. Grain Weighing System: An accurate weighing system is integrated to ensure precise filling of each bag with the desired weight of grain.

4. Filling Unit: The filling unit is designed to gently and efficiently fill the grain into the bags, minimizing product damage and ensuring proper filling levels.

5. Sealing System: The machine features a reliable sealing system that creates airtight and secure seals, preserving the quality and freshness of the packaged grain.

6. Conveying System: A conveyor belt or elevator system is included to transport filled bags away from the machine for further processing or packaging.

Customer case

| Packaging Case | Packaging Materials | Packing volume | Packing size |

| A grain processing company uses Full Auto Vertical Grain Packing Machine to transport grains such as rice and wheat from storage silos to packaging machines for automated packaging. The equipment is equipped with a dual servo motor drive system that can flexibly adjust the bag length and cutting accuracy to ensure packaging efficiency and quality. The production line can process 8 tons of materials per hour and is widely used in grain processing and storage industries. | Rice, wheat, corn and other grains | 8 tons/hour | 5kg, 10kg, 25kg and other specifications |

| A feed production company uses Full Auto Vertical Grain Packing Machine to transport feed pellets from the end of the production line to the packaging machine. The equipment is made of stainless steel and is suitable for the feed industry with high hygiene requirements. Through the PLC control system, the equipment can achieve accurate metering and fast packaging, and can process 10 tons of feed pellets per hour, significantly improving production efficiency | Animal feed pellets | 10 tons/hour | 20kg, 50kg and other large bag packaging |

| A food processing company uses Full Auto Vertical Grain Packing Machine for quantitative packaging of nuts and seeds. The equipment is equipped with a high-sensitivity photoelectric tracking system to ensure the sealing and cutting accuracy of the packaging bags. Through the touch screen operation interface, workers can quickly adjust parameters to meet the packaging needs of different specifications. The equipment can process 5 tons of materials per hour and is widely used in the snack food industry | Peanuts, melon seeds, nuts, etc. | 5 tons/hour | 1kg, 2kg, 5kg and other small bag packaging |

How to Select Full Auto Vertical Grain Packing Machine?

| Material characteristics | Particle size: According to the particle size of the material (such as rice, wheat, nuts, etc.), select a suitable feeding system (such as spiral feeding, vibration feeding, etc.) to ensure smooth material flow and avoid blockage. |

| Flowability: Materials with good flowability (such as grains) are suitable for gravity feeding systems, while materials with poor flowability (such as powders) may require spiral feeding or vibration feeding systems | |

| Humidity and viscosity: High humidity or sticky materials need to choose anti-adhesion design and be equipped with cleaning devices to prevent materials from adhering to the inside of the equipment. | |

| Corrosiveness: For corrosive materials (such as certain chemical particles), stainless steel materials need to be selected to improve the durability of the equipment. | |

| Packaging size | Bag length and bag width: Select the appropriate packaging size range according to product requirements. For example, vertical packaging machines usually support packaging sizes of 60-300mm in bag length and 60-200mm in bag width. |

| Packaging form: Select the packaging form according to product characteristics, such as flat bags, three-dimensional bags or back-sealed bags. Different forms have different requirements for the bag making mechanism and sealing system of the equipment. | |

| Packaging volume | Single bag weight: Select equipment according to the single bag weight requirements. For example, some equipment supports large bag packaging of 25kg-2 tons/bag, while small bag packaging is suitable for specifications of 1kg-10kg. |

| Packaging accuracy: High-precision packaging (such as ±0.2%) is suitable for industries with strict measurement requirements (such as medicine and food), and equipment equipped with precision sensors must be selected. | |

| Packaging speed | Production efficiency: Select the packaging speed according to production needs. The packaging speed of conventional equipment is 5-60 bags/minute, and high-speed equipment can reach more than 200 bags/minute. |

| Automation degree: Highly automated equipment (such as equipped with PLC and servo motor) can achieve high-speed and high-precision packaging, which is suitable for mass production. | |

| Other selection considerations | Material selection: The food industry needs to choose stainless steel to ensure hygiene and safety; ordinary industry can choose carbon steel to reduce costs. |

| Additional functions: Choose functions such as inflation, exhaust, coding, counting, etc. according to your needs to improve the packaging effect and product image. | |

| Environmental adaptability: Consider the dust and moisture resistance of the equipment, especially in high humidity or dusty environments. |

What is the full auto vertical grain packing machine price?

The price of a full auto vertical grain packing machine can vary significantly based on several factors, including the machine's capacity, features, brand, and the supplier or manufacturer you choose. Generally, these machines can range in price from several thousand dollars to tens of thousands of dollars.

It's important to note that pricing information can change over time, and it's best to reach out directly to packaging machine suppliers or manufacturers for the most accurate and up-to-date pricing information. They can provide you with detailed quotes based on your specific requirements and provide information on any additional costs, such as installation, training, or warranty.

Full auto vertical grain packing machine manufacturers China

Xinxiang Dahan is a professional manufacturer of fully automatic vertical grain packaging machines. The company is committed to designing, developing and producing high-quality grain packaging machines to meet customers' efficient and accurate needs for grain packaging. Xinxiang Dahan uses advanced technology and engineering expertise to provide customizable solutions to suit different grain types and packaging needs. Their fully automatic vertical grain packaging machines feature precise weighing, filling and sealing capabilities to increase production efficiency and ensure packaging consistency. The company focuses on product quality, reliability and customer satisfaction and provides comprehensive after-sales support, including installation, training and maintenance services. As a trustworthy manufacturer, Xinxiang Dahan always aims for high-quality machines and excellent customer service, ensuring that its fully automatic vertical grain packaging machines meet industry standards and provide efficient and accurate grain packaging solutions.