What is a fully automatic spiral packaging machine?

Fully automatic spiral packaging machine is an automated packaging equipment that is widely used in food, pharmaceuticals, cosmetics and other industries. It uses a spiral conveyor system to automatically feed the product into the packaging machine. After a series of packaging processes, the product is finally encapsulated and packaged. The fully automatic spiral packaging machine has a high degree of reliability, stability and production efficiency, and can significantly increase the packaging speed and production capacity of the production line.

How does the fully automatic spiral packaging machine work?

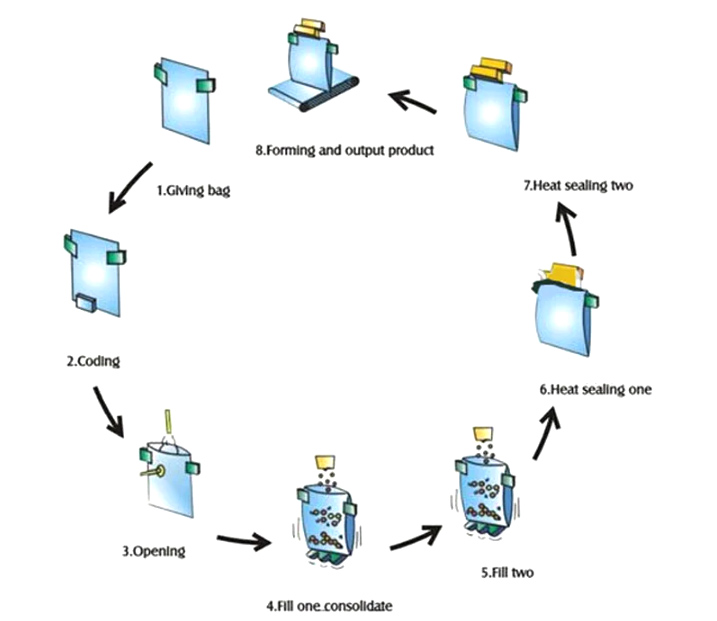

The fully automatic spiral packaging machine streamlines the packaging process by automatically handling material feeding, measuring, bag forming, sealing, and output. It begins with material preparation at the feed port (manual or automated loading), followed by a screw conveyor that transports materials via rotating spiral blades to the vertical packaging unit. The machine then precisely packages the materials based on preset parameters, performing dosing, sealing, and date printing as needed. Finally, the finished packaged products are discharged for subsequent steps like quality checks, labeling, or palletizing. This integrated system ensures efficient, consistent, and high-quality packaging with minimal manual intervention.

What are the applications of fully automatic spiral packaging machines?

Fully automatic spiral packaging machine is widely used in the following industries:

Food industry: It can be used for food processing and packaging, such as automated packaging of potato chips, biscuits, candies, coffee beans, etc. It can improve packaging speed and accuracy and ensure the sealing and freshness of food.

Beverage industry: used for packaging of bottled beverages. It can automatically transport bottled beverages to the packaging machine for sealing, labeling and packaging, improving production efficiency and product appearance consistency.

Pharmaceutical industry: can be used for packaging of pharmaceutical products, such as tablets, capsules, medicine bottles, etc. It can automate the packaging process and ensure the safety and hygiene of medicines.

Daily necessities industry: It can be used in the packaging of various daily necessities, such as shampoo, shower gel, washing powder, etc. It can improve packaging efficiency and ensure the appearance and quality of products.

Live Video

Features of fully automatic spiral packaging machine

As a fully automated packaging equipment, the fully automatic spiral packaging machine is a widely used equipment in the packaging industry. The following are some of the main advantages of the fully automatic spiral packaging machine:

Efficient automation: The fully automatic spiral packaging machine can achieve high-speed, continuous packaging operations, greatly improving production efficiency and capacity.

Stable and reliable: Using advanced control systems and sensors, the fully automatic spiral packaging machine can maintain a stable working condition and ensure packaging accuracy and consistency.

Flexible adaptability: The fully automatic spiral packaging machine has strong adaptability and can be applied to products of different shapes, sizes and types to meet diverse packaging needs.

Easy operation and maintenance: Fully automatic spiral packaging machines are usually equipped with user-friendly operating interfaces and maintenance systems, making it convenient for operators to perform setting, monitoring and maintenance work.

Fully automatic spiral packaging machine model

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

Structure of fully automatic spiral packaging machine

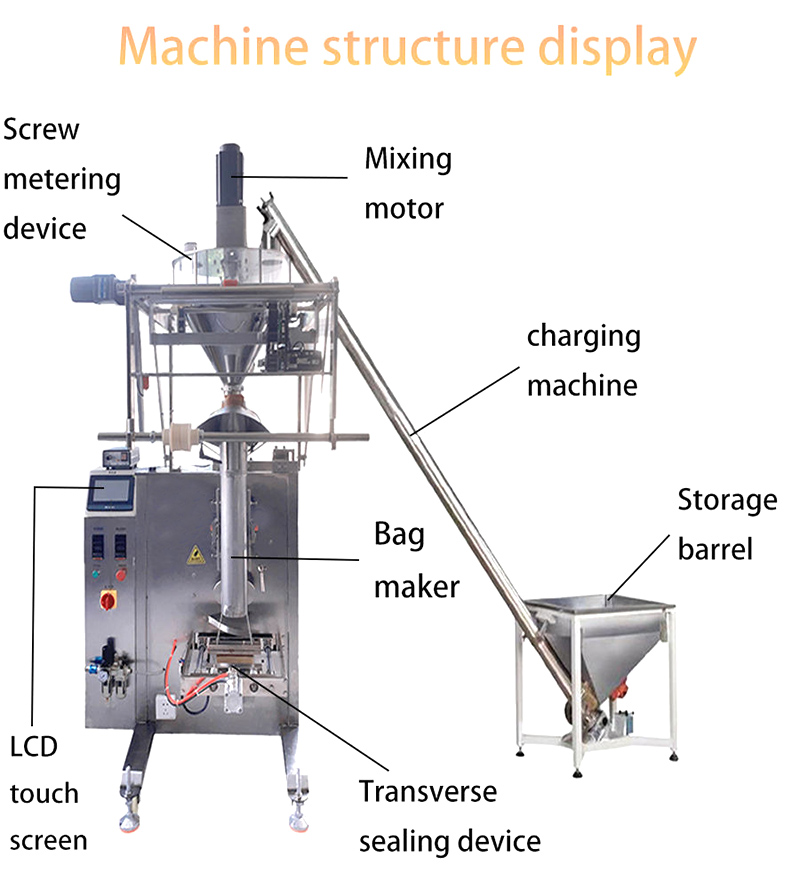

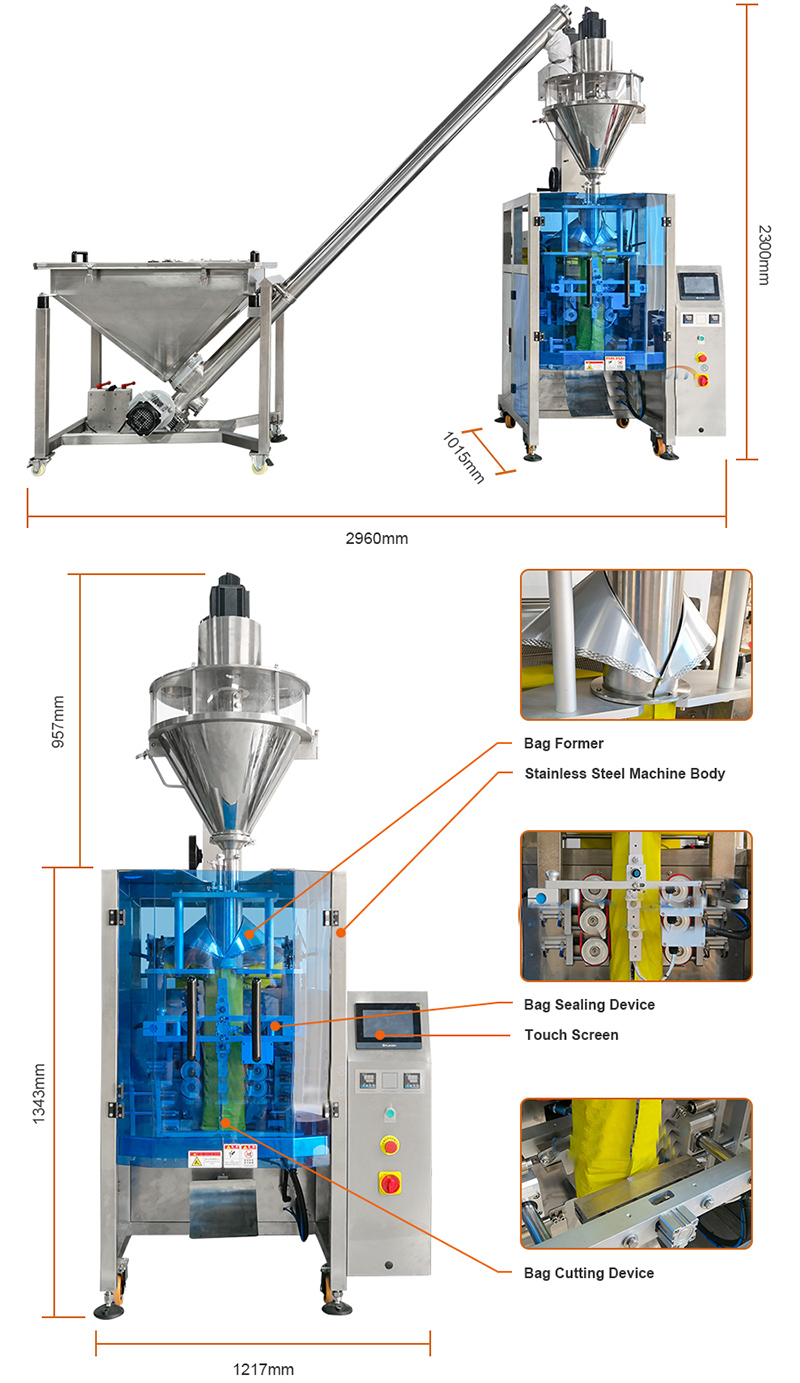

The structure of a fully automatic spiral packaging machine generally includes the following main components:

Feed port: Materials enter the spiral feeding packaging machine through the feed port. This is the initial input location of the material.

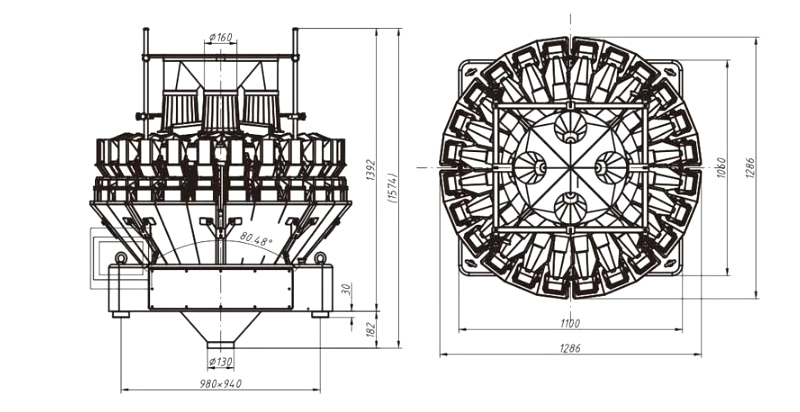

Screw conveyor: The screw conveyor is the core component of the screw feed packaging machine. It consists of spiral blades that can transport materials from the feed port to the working area of the packaging machine.

Packaging mechanism: The packaging mechanism is the part used to package materials. It may include quantitative metering devices, sealing devices, heat sealers, cutting devices, etc. These units are designed based on specific packaging requirements and product characteristics.

Control system: A fully automatic spiral packaging machine is usually equipped with a control system to monitor and control the entire packaging process. The control system can adjust parameters such as packaging speed, sealing temperature, and measurement accuracy to ensure packaging accuracy and consistency.

Discharge port: After packaging is completed, the materials are discharged from the spiral feed packaging machine through the discharge port. This is the output location for packaged products.

Customer case

| Application Scenario | Packaging speed | Packaging volume | Packaging size | Packaging bag material |

| A food processing company uses a fully automatic spiral packaging machine to quantitatively package mixed nuts (such as cashews and almonds) | 150~200 bags/minute (medium and high speed mode) | 25g~100g per bag (adjustable) | 30~50mm wide, 80~150mm long | PE composite film (moisture-proof, wear-resistant) |

| A pharmaceutical company uses a fully automatic spiral packaging machine to package tablet drugs with high precision to ensure compliance with GMP standards | 80~120 packages/minute (high-precision mode) | 10~50 tablets per package (customizable) | 15~30mm wide, 50~100mm long | AL (aluminum foil) composite film (high barrier, anti-oxidation) |

| A chemical company uses a fully automatic spiral packaging machine to perform dust-free packaging of fine chemical powders (such as titanium dioxide) | 60~100 bags/minute (dust-proof low-speed mode) | 500g~5kg per bag (large-capacity packaging) | 50~100mm wide, 200~400mm long | PET/AL composite bag (moisture-proof, anti-static) |

| A fastener manufacturer uses a fully automatic spiral packaging machine to automatically count and package screws and bolts to replace manual sorting | 120~180 bags/minute (medium-speed mode) | 50~200 pieces per bag (adjustable) | 20~40mm wide, 100~200mm long | PVC film (wear-resistant, low-cost) |

| An e-commerce storage center uses a fully automatic spiral packaging machine to cushion fragile goods (such as glass products) to replace traditional manual film wrapping | 40~80 packages/minute (low-speed protection mode) | Single-piece packaging (customized) | Wide adjustable range (up to 500mm) | PE stretch film (high elasticity, shockproof) |

How to Choose Fully Automatic Spiral Packaging Machine?

In addition to the above main components, the fully automatic spiral packaging machin may also include auxiliary components such as feed conveyor belts, conveyor belt adjustment devices, and protective covers to provide a more complete packaging solution.

| Packaging Product | Type of Packaging | Packaging Materials | Packaging volume (per minute) |

| coffee powder | bagged | foil bag | 250 |

| pill | bottled | plastic bottle | 100 |

| instant noodles | bagged | composite film | 85 |

| fertilizer | bagged | woven bag | 50 |

| washing powder | bagged | plastic bag | 30 |

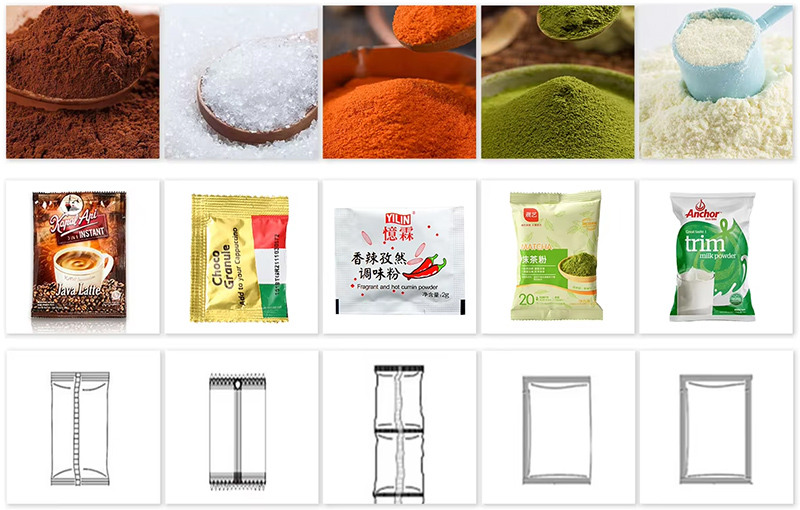

Packaging materials

First of all, we need to consider what materials are to be packaged.

Granular materials: such as nuts, candies, screws, bolts, feed pellets, etc.; Screw head design: wear-resistant materials (such as tungsten carbide coating) are required to cope with the friction of hard particles.

Powdered materials: such as milk powder, seasoning powder, chemical powder, etc.; sealed screw feeding system to reduce dust spillage.

Flake/fibrous materials, such as potato chips, dried flowers, tobacco, fiber fillers, etc.

Special materials (such as fragile, high-viscosity materials), such as biscuits, chocolate, paste chemicals, etc.

Packaging speed

Low-speed model: 20~50 packs/minute, suitable for small batches and high precision requirements (such as medicines and precision parts).

Medium-speed model: 50~150 packs/minute, general-purpose, suitable for medium-scale production such as food and daily chemicals.

High-speed model: 150~300 packs/minute, suitable for large-scale standardized products (such as candy and fasteners).

Packaging accuracy

The packaging accuracy refers to the accuracy of the packaging machine in measuring materials. The higher the packaging accuracy, the more reliable the product quality.

Ordinary grade: ±1~2% (applicable to food and hardware).

High-precision grade: within ±0.5% (medicine and high-value products need to be equipped with weighing sensors).

Sealing accuracy: The heat sealing position deviation must be ≤1mm to avoid leakage or opening.

Packaging size

The packaging size refers to the size of the packaged product. The packaging size range of the packaging machine should be greater than or equal to the product size.

Diameter range: Common spiral packaging machines support Φ10~150mm, special models can be customized.

Length range: Usually 50~500mm, extra-long packaging requires customized conveyor belts.

Common packaging bag materials

PE (polyethylene): general purpose, suitable for conventional products such as food and daily chemicals.

PP (polypropylene): high temperature resistant, suitable for products that require heat sealing or high temperature sterilization (such as medicine).

PET/AL (aluminum-plastic composite film): high barrier properties, used for easily oxidized products (such as high-end food and medicine).

PVC (polyvinyl chloride): low cost, but poor environmental protection, must comply with local regulations.

Functional requirements

The fully automatic spiral packaging machine can be configured with various functions, such as coding, sealing, cutting, external exhaust, etc. When selecting equipment, it is necessary to select the appropriate configuration according to actual needs.

Fully automatic spiral packaging machine manufacturers

Xinxiang Dahan fully automatic spiral packaging machine manufacturers are a leading company in the field of manufacturing fully automatic spiral packaging machines. They specialize in designing and producing advanced packaging solutions that automate the process of wrapping various products with a spiral film. With a focus on quality , efficiency, and innovation, New Xiang Da Han's machines are widely used in industries such as food, beverage, pharmaceuticals, and logistics. Their fully automatic spiral packaging machines offer precise and reliable packaging, ensuring product protection, stability, and aesthetic appeal. With With their expertise and commitment to customer satisfaction, New Xiang Da Han is a trusted manufacturer in the packaging industry.