Fully Automatic Vertical Nitrogen Potato Chips Weighing Packaging Machine for Potato Chips

Fully Automatic Vertical Nitrogen Potato Chips Weighing Packaging Machine for Potato Chips can complete the tasks of weighing, packaging and sealing potato chips. Nitrogen filling can reduce the oxidative effect of oxygen on food and extend the shelf life of food. Due to its flexible structure and adjustable packaging parameters, it can package other granular, puffed and other foods.

Supply different models of fully automatic vertical nitrogen-filled potato chips weighing and packaging machines

Each packaging machine has its specific scope of application and advantages. Choosing a suitable packaging machine according to the characteristics of the product and packaging requirements can improve production efficiency, ensure packaging quality, and reduce production costs. The following are the types of packaging machines with different gram weights:

ZP-series: packaging speed is 30-60 packs per minute, packaging accuracy is ±2g, suitable for small-scale production enterprises.

ZD-series: packaging speed is 60-90 packs per minute, packaging accuracy is ±1g, suitable for medium-scale production enterprises.

ZS-series: packaging speed is 90-120 packs per minute, packaging accuracy is ±0.5g, suitable for large-scale production enterprises.

Live video

Application of fully automatic vertical nitrogen-filled potato chips weighing and packaging machine

The fully automatic vertical nitrogen-filled potato chip weighing and packaging machine is widely used in potato chip production enterprises. Due to its flexibility and versatility, it can also adapt to foods of different shapes and sizes as needed. The following are the main application scenarios of this packaging machine

Puffed foods: potato chips, French fries, corn cobs, shrimp crackers, rice crackers, cat ears, etc.

Dry foods: melon seeds, peanuts, pistachios, walnuts, almonds, cashews, etc.

Snack foods: seaweed, dried tofu, broad beans, candied fruits, plums, etc.

Granular foods: tea leaves, coffee beans, candies, chocolate beans, cereals, etc.

What are the characteristics of the fully automatic vertical nitrogen-filled potato chips weighing and packaging machine?

1. Nitrogen filling for freshness, extending the shelf life by 3 times

99.9% high-purity nitrogen replacement, residual oxygen content <1%, effectively inhibiting oxidation, keeping the crisp taste of potato chips longer; anti-shatter design, soft landing unloading + airflow buffering, reducing the transportation damage rate by 80%.

2. Ultra-high-speed packaging, efficiency crushes labor

70 bags/minute (50g standard bag), 1 ton of potato chips packaging is completed in 1 hour, replacing 20 workers; 10-head combination weigher accurately measures, with an error of only ±0.2%, eliminating short weight.

3. Intelligent anti-blocking, 24-hour continuous operation

Ultrasonic net cleaning + airflow assistance, completely solve the problem of potato chips sticking to the net, and reduce downtime by 90%; Fully automatic alarm system, real-time monitoring of nitrogen pressure, temperature, film roll status, and fault self-diagnosis.

4. One machine for multiple uses, suitable for all-scenario packaging

10-1500g wide range, one-click switch from mini bags to family bags, supports pillow bags, three-dimensional bags, and handbags; food-grade 304/316 stainless steel, FDA-compliant, easily passes export certification.

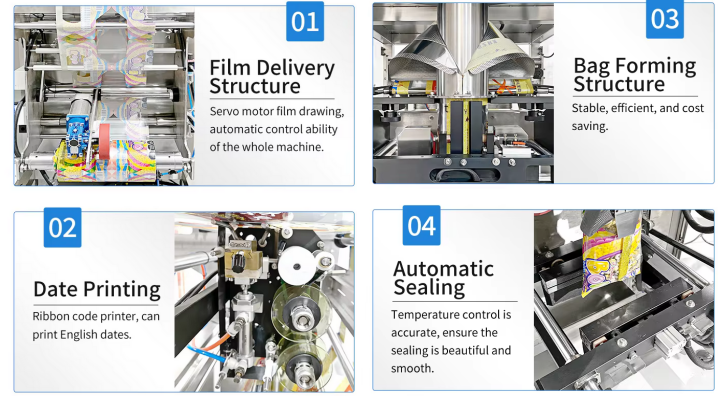

How does the fully automatic vertical nitrogen-filled potato chips weighing and packaging machine work?

Fully automatic vertical nitrogen potato chips weighing packaging machine for potato chips uses the "vertical forming-filling-sealing" technology to quickly and accurately package potato chips and fill them with nitrogen for fresh-keeping: the roll film is automatically formed into a bag body → 10-head electronic combination scale accurately weighs (error ±0.2%) → potato chips softly land into the bag → 99.9% high-purity nitrogen is injected after vacuuming (residual oxygen content <1%) → heat seal cutting → finished product output, and the whole process runs at a high speed of 70 bags/minute. The equipment is made of food-grade stainless steel and is suitable for a variety of packaging specifications from 10 to 1500g. After nitrogen filling, the shelf life of potato chips is extended by 3 times, and the transportation damage rate is reduced by 80%. It is the ultimate solution for fresh-keeping packaging of puffed food!

Fully Automatic Vertical Nitrogen Potato Chips Weighing Packaging Machine for Potato Chips Parameter

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

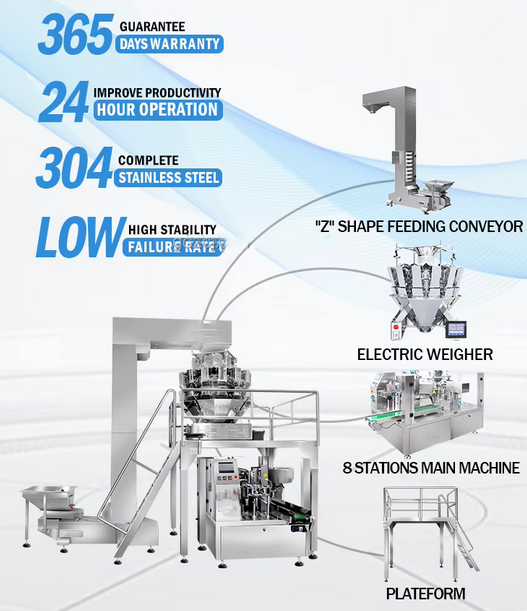

Structure of fully automatic vertical nitrogen-filled potato chip weighing and packaging machine

The fully automatic vertical nitrogen-filled potato chip weighing and packaging machine is usually composed of a conveying system, a self-supporting bag supply system, a filling system, a vacuum system, a sealing system, a cutting system, a control system, a detection system and a discharging system. These components work together to convey food, provide self-supporting bags, accurately fill food, remove air, seal, cut, control operation, detect packaging quality and discharge packaging bags to achieve an efficient and accurate food packaging process and extend the shelf life of food. It is suitable for the packaging needs of potato chips, puffed foods, nuts, candies, dried fruits, cakes, snacks and other foods.

Fully automatic vertical nitrogen-filled potato chips weighing and packaging machine customer cases

| Application scenario | Packing volume | Packing speed | Packing size | Packaging bag material |

| The puffed food production line of an international snack brand (such as Lay's, Copic, etc.) needs to extend the shelf life of potato chips and prevent them from breaking during transportation. | 50g/bag (adjustable range 10-1500ml) | 70 bags/minute | 150-200mm long × 80-120mm wide (pillow bag) | Multi-layer composite film (PET/AL/PE, oxygen barrier and moisture proof) |

| A regional potato chip brand in Southeast Asia, which needs to adapt to multiple specifications (such as 30g/80g/120g) and has a limited budget. | 30-150g/bag (programmable switching) | 40 bags/minute (economical configuration) | 100-180mm long × 60-100mm wide (gusseted handbag) | OPP/CPP (transparent, low cost) |

| Organic sweet potato chips, quinoa chips and other fragile high value-added products need to prevent oxidation and maintain a crispy taste. | 25g/bag (high-precision weighing) | 30 bags/minute | 120-150mm long × 70-90mm wide (four-side sealed three-dimensional bag) | KNY/PE (high barrier, biodegradable) |

| Internet celebrity snack brands, need to frequently change packaging design (such as holiday limited edition) | 20-100g/bag (support mini bags to family packs) | 25-50 bags/minute (adjusted according to bag type) | 80-300mm long × 50-200mm wide (support special-shaped bags) | Matte aluminum film (enhance visual texture) |

Thursday September-04 2025 16:28:56