Fully Intelligent for Automatic Rice Packaging Machine

Fully Intelligent for Automatic Rice Packaging Machine combines advanced intelligent technology and can realize a fully automated packaging process. Automatic Rice Packing Machine widely used in grain processing, rice wholesale, supermarkets, food processing and other industries.

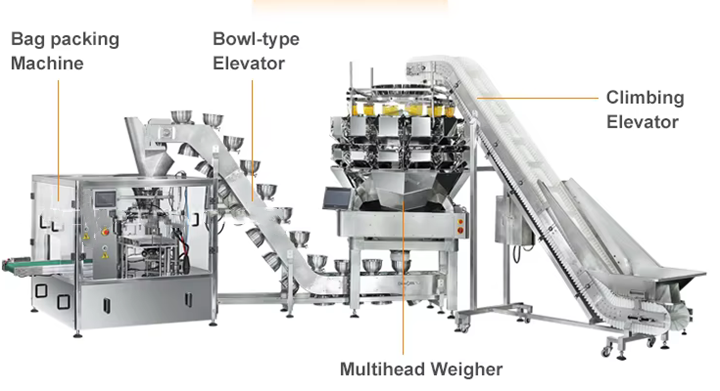

Composition of fully automatic intelligent rice packaging machine

Feeding system: a device for supplying rice to the packaging area.

Cleaning and handling system: a device for cleaning and handling rice.

Weighing system: a device for accurately measuring the weight of rice, usually including a high-precision weighing sensor.

Packaging material supply system: a device for providing packaging bags or containers, which may include a roll film or bag material supply device.

Filling system: a device for filling rice into packaging bags or containers.

Sealing system: a device for sealing packaging bags or containers, which can use methods such as heat sealing, ultrasonic sealing or pressure sealing.

Label and identification system: a device for adding labels, printing production date, batch number and other information.

Detection system: a device for detecting the integrity of packaging bags or containers, weight accuracy, etc.

PLC control system: a device for monitoring and controlling the entire packaging process.

How does the fully automatic intelligent rice packaging machine work?

-Rice feeding: rice is supplied to the packaging area through the feeding system.

-Cleaning and processing: The rice undergoes necessary processing operations through the cleaning and processing system.

-Weighing and metering: The rice enters the weighing system, which accurately measures the weight of the rice and meters it according to the preset packaging requirements.

-Packaging material supply: The packaging material supply system provides packaging bags or containers.

-Filling: The rice is automatically filled into packaging bags or containers to ensure accurate filling and filling.

-Sealing and sealing: The sealing system seals the packaging bags or containers to maintain sealing and freshness.

-Labeling and identification: The labeling and identification system adds labels, prints production date, batch number and other information.

Detection and exclusion: The detection system detects the integrity, weight accuracy, etc. of the packaging bags or containers, and automatically excludes unqualified products.

-Control and monitoring: The control system monitors and controls the entire packaging process, and the operator can set packaging parameters, monitor production progress and adjust the equipment operation mode.

Advantages of fully automatic intelligent rice packaging machine

Automated operation: reduce manual intervention, improve production efficiency and consistency.

High-precision weighing: equipped with a high-precision weighing system, it can accurately measure the weight of rice to ensure the accuracy and stability of packaging.

Diversified packaging: can adapt to packaging bags or containers of different specifications and forms, and can be flexibly adjusted and adapted to different packaging needs.

Quick changeover: with the ability to quickly change, it can quickly adjust to different packaging specifications and material characteristics.

Intelligent control: equipped with advanced control system, with intelligent functions.

Data recording and traceability: can record production data, packaging parameters and batch information, and realize product traceability and quality management.

Scope of application of fully automatic intelligent rice packaging machine

Cereals and grains: In addition to rice, fully automatic intelligent packaging machines can also be used to package wheat, corn, oats, barley and other grains and grains.

Dried fruits and nuts: Dried fruits such as raisins, dates, cranberries and nuts such as almonds, walnuts, cashews, etc.

Beans and potatoes: beans, red beans, mung beans, black beans and potato flour, potato chips, etc.

Condiments and powdered foods: Condiments, salt, sugar, pepper and powdered foods, flour, milk powder, coffee powder are also products that can be packaged by packaging machines.

Cosmetics and personal care products: Fully automatic intelligent packaging machines can also be used to package granular or powdered cosmetics and personal care products, such as flour, shampoo powder, laundry detergent, etc.

Tuesday July-09 2024 17:01:10