Seasoning Powder for Fully Automatic Weighing And Packaging Machine

Seasoning powder (such as chicken powder, thirteen spices, chili powder, cumin powder, etc.) is easy to generate dust and has large differences in fluidity. Traditional manual packaging is prone to errors, pollution and low efficiency. Seasoning Powder for Fully Automatic Weighing And Packaging Machine perfectly solves the packaging problem of seasoning powder through high-precision screw metering, intelligent adaptive algorithm, and closed dust-proof design.

Compared with traditional semi-automatic packaging equipment, Seasoning Powder for Fully Automatic Weighing And Packaging Machine has three core advantages in the seasoning powder industry: high metering accuracy (up to ±0.5%-±1%), fast packaging speed (40-150 packs/minute) and high degree of automation (reducing manual intervention).

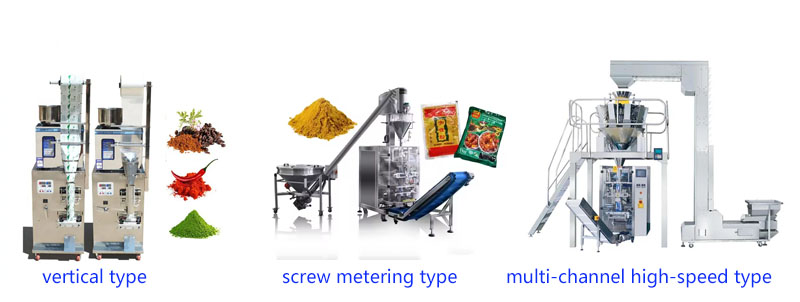

What types of Seasoning Powder for Fully Automatic Weighing And Packaging Machine are there?

Seasoning Powder for Fully Automatic Weighing And Packaging Machine can be divided into three types according to the characteristics of different seasoning powders and packaging requirements: vertical type, screw metering type, and multi-channel high-speed type.

Vertical Seasoning Powder for Fully Automatic Weighing And Packaging Machine: It has integrated bag making, filling, and sealing, supports back-sealed bags, self-supporting bags, and box bags, and can package seasoning powders with good fluidity (such as monosodium glutamate, powdered sugar, and pepper powder).

Screw metering seasoning powder packaging machine: uses spiral filling and adaptive three-speed (fast-medium-slow) feeding to reduce errors. It can package seasoning powders that are easy to generate dust and have poor fluidity (such as chili powder and compound seasonings).

Multi-channel high-speed seasoning powder packaging machine: It uses multi-station synchronous packaging, with a speed of more than 60 bags/minute, which is suitable for large-scale production, such as chicken powder, thirteen spices, etc.

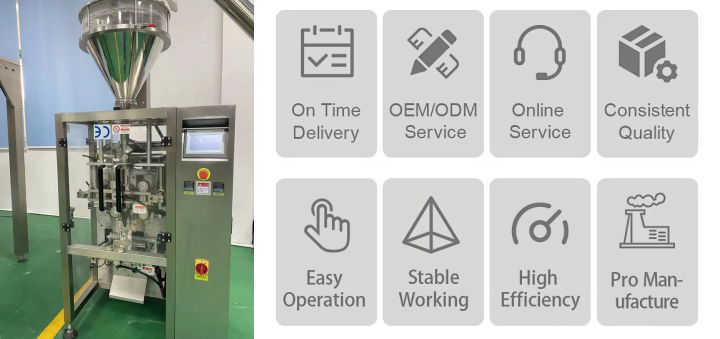

What are the advantages of Seasoning Powder for Fully Automatic Weighing And Packaging Machine?

High-precision metering: adopt stepper motor to control screw filling, with an accuracy of ±0.5%-±2%, reducing the waste of raw materials.

Fully automated production: automatically complete feeding, metering, bag making, sealing, and coding, 40-150 bags/minute, and increase efficiency by 80%.

Dustproof sealing structure: closed design, reduce dust pollution, meet GMP standards, and ensure food safety.

Intelligent formula management: touch screen operation, can store a variety of seasoning powder formulas (such as different gram weights, drop compensation), one-click switching.

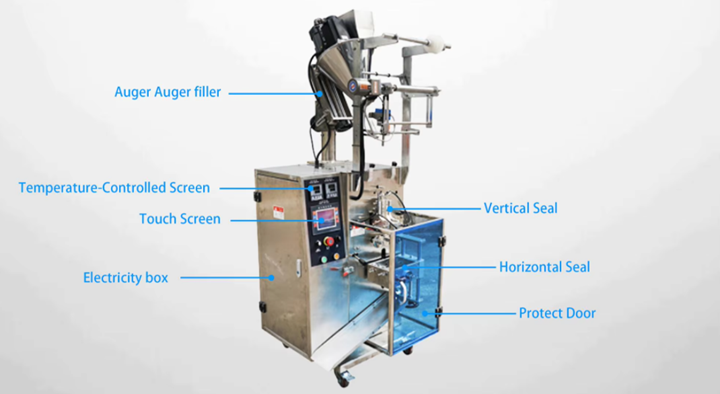

What are the structural components of Seasoning Powder for Fully Automatic Weighing And Packaging Machine?

Seasoning powder fully automatic weighing and packaging machine usually consists of the following main components:

Feeding system: This part is used to transport seasoning powder from storage bins or other storage equipment to the weighing bucket of the weighing packaging machine.

Weighing system: The weighing system is the core component of the seasoning powder fully automatic weighing packaging machine. It usually consists of multiple weighing buckets.

Control system: The control system includes the main control panel and program to set the weight, speed, packaging specifications and other parameters of the packaging.

Packing mechanism: The packaging mechanism is responsible for putting the weighed seasoning powder into bags or other packaging containers, and completing the packaging steps such as sealing and printing the production date.

Conveying system: The conveying system is used to transport the packaged seasoning powder products to the next production stage or packaging area to ensure the continuous operation of the production line.

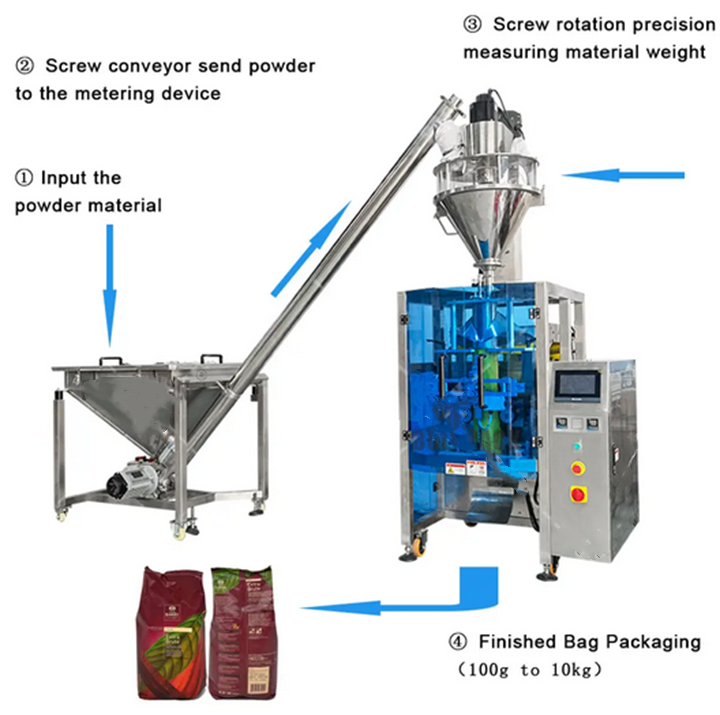

How does the seasoning powder for Fully automatic weighing and packaging machine work?

The working principle of the seasoning powder for Fully automatic weighing and packaging machine usually includes the following steps:

Feeding stage: The seasoning powder is transported from the storage bin or other storage equipment to the weighing hopper of the weighing packaging machine through the feeding system to wait for weighing.

Weighing stage: Once the seasoning powder enters the weighing hopper, the weighing sensor measures its weight. According to the preset packaging weight, the control system adjusts the amount of seasoning powder in the weighing hopper.

Packing stage: The stable seasoning powder weight is transmitted to the packaging mechanism. Here, the seasoning powder is loaded into the prepared packaging bag. Usually, this includes steps such as bag forming, filling, sealing and labeling.

Conveying stage: The filled packaging bag is moved to the next workstation or packaging area through the conveying system for subsequent packaging processing or transportation.

What are the applicable scopes of Seasoning powder for Fully automatic weighing and packaging machine?

Seasoning Powder for Fully Automatic Weighing And Packaging Machine can be used to pack various powder and granular seasonings, such as compound seasonings (thirteen spices, curry powder, barbecue powder), single seasoning powder (chicken powder, monosodium glutamate, chili powder, cumin powder), food additives (yeast powder, leavening agent, flavor powder), etc.

Seasoning Powder for Fully Automatic Weighing And Packaging Machine Customer Case

| Application scenario | Packing volume | Packing speed | Packing size | Packing bag material |

| A high-end food company in India: The export packaging of compound seasoning powder (such as thirteen spices and curry powder) must comply with European and American food standards. | 200g/bag | 80 bags/minute | Back-sealed bag, size L=150mm × W=100mm. | Food-grade aluminum foil composite film (moisture-proof and light-proof) |

| Anhui seasoning factory: high-speed continuous packaging of chicken powder and cumin powder | 100g/bag | 150 bags/minute | Self-supporting bag, size L=120mm × W=80mm | PE/aluminum-plated film (anti-static, easy to stand display) |

| A meat product factory in Nigeria: pre-prepared dish seasoning (marinade powder, barbecue powder packaging), small bags of diversified packaging are required | 20g/bag | 60 bags/minute | Three-side sealed bag, size L=80mm × W=60mm | Transparent OPP/CPP (display contents) |

How much is Seasoning Powder for Fully Automatic Weighing And Packaging Machine?

The price of a Seasoning Powder for Fully Automatic Weighing And Packaging Machine is usually between $400 and over $50,000 per unit, depending on the specifications and configuration. The main factors affecting the price are packaging volume and speed (machines with faster packaging speeds (e.g., 40-60 bags/minute) and a larger weight range (50 grams-5 kg) are more expensive), material and construction (food-grade stainless steel construction costs more compared to carbon steel models.), customization and add-ons (options such as nitrogen flushing, metal detection or multi-head weighing will increase the price), etc.

Dahan Seasoning Powder for Fully Automatic Weighing And Packaging Machine has become the core equipment for seasoning powder production. Whether it is chicken powder, thirteen spices, or compound seasonings, automatic packaging can not only improve efficiency by more than 30%, but also ensure the weight consistency of each package of products and reduce the risk of contamination caused by manual intervention.

Wednesday September-03 2025 17:46:57