What is a Fully Automatic Multihead Packaging Machine?

Friday January-19 2024 13:54:15

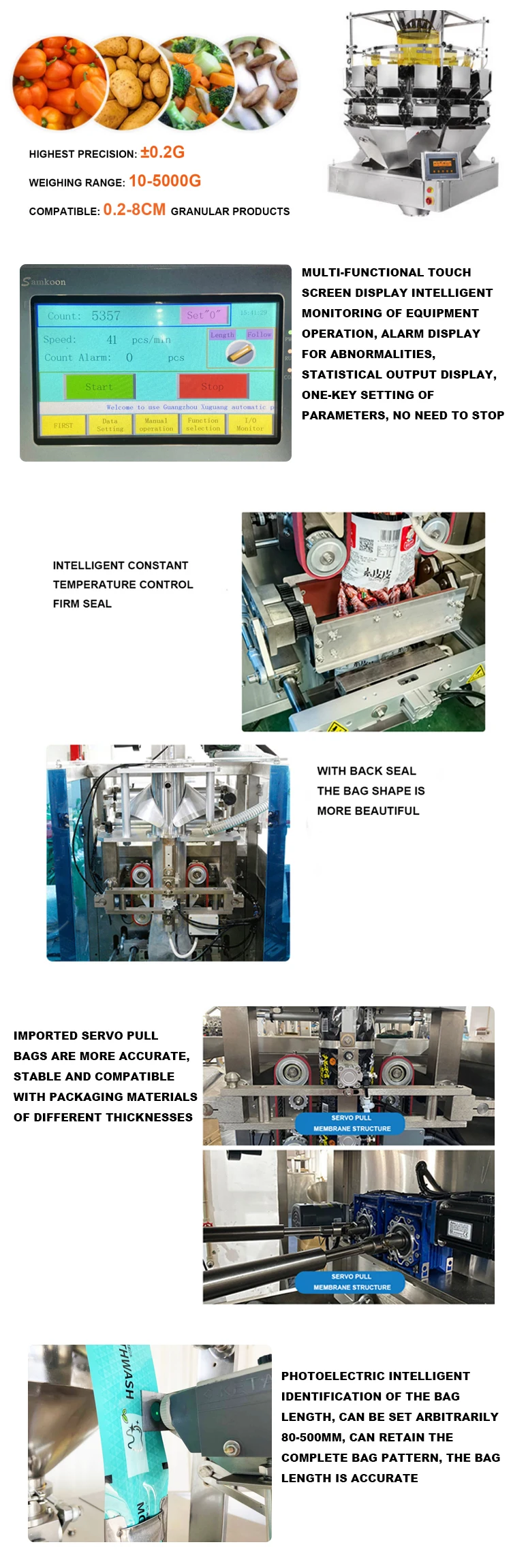

Fully automatic multihead packaging machine price is a sophisticated piece of equipment used in the packaging industry to automate the process of weighing and packaging products. It combines multiple weighing heads with advanced control systems to achieve high-speed and accurate packaging.

How does a fully automatic multihead packaging machine work?

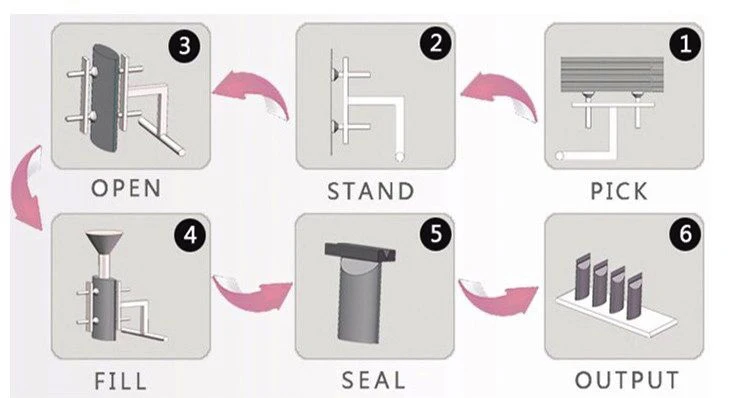

Fully automatic multi-head packaging machine is an efficient and automated packaging equipment that can quickly and accurately complete the weighing, packaging and sealing of products. The following is a brief introduction to the working principle of the fully automatic multi-head packaging machine:

1. Product supply: The packaged products enter the hopper or feed channel of the multi-head packaging machine through the supply system. These feed systems can be customized as needed to accommodate different types and shapes of products.

2. Weighing and measuring: The multi-head packaging machine is equipped with multiple independent weighing devices, each weighing device corresponds to a hopper. Once the product enters the hopper, the scale quickly and accurately measures the product's weight. Weighers often use technology such as load cells or vibrators to ensure accurate weighing results.

3. Packaging and sealing: Once the weighing is completed, the packaging machine pours the correct amount of product into the pre-prepared packaging container according to the preset parameters. Containers can be bags, jars, boxes or other types of packaging. The machine will then automatically perform the sealing operation to ensure the sealing and integrity of the package.

3. Output and discharge: After completing packaging and sealing, the packaged products can be collected and discharged through conveyor belts or other output systems for further processing, storage or transportation.

Advantages of fully automatic multihead packaging machine

Fully automatic multihead packaging machines offer several advantages over manual or semi-automatic packaging methods. Here are some key advantages:

1.High Efficiency: Fully automatic multihead packaging machines are designed to operate at high speeds, significantly increasing packaging efficiency and productivity. They can handle large volumes of products, reducing packaging time and increasing output.

2.Accuracy and Consistency: These machines utilize advanced weighing systems and sensors to ensure accurate and consistent product measurements. The precise weighing technology helps maintain uniformity in package contents, meeting quality standards and customer expectations.

3.Labor and Cost Savings: By automating the packaging process, fully automatic multihead machines reduce the reliance on manual labor. Fewer operators are required, leading to cost savings in terms of labor expenses. Additionally, the increased efficiency and productivity result in higher output without compromising on quality.

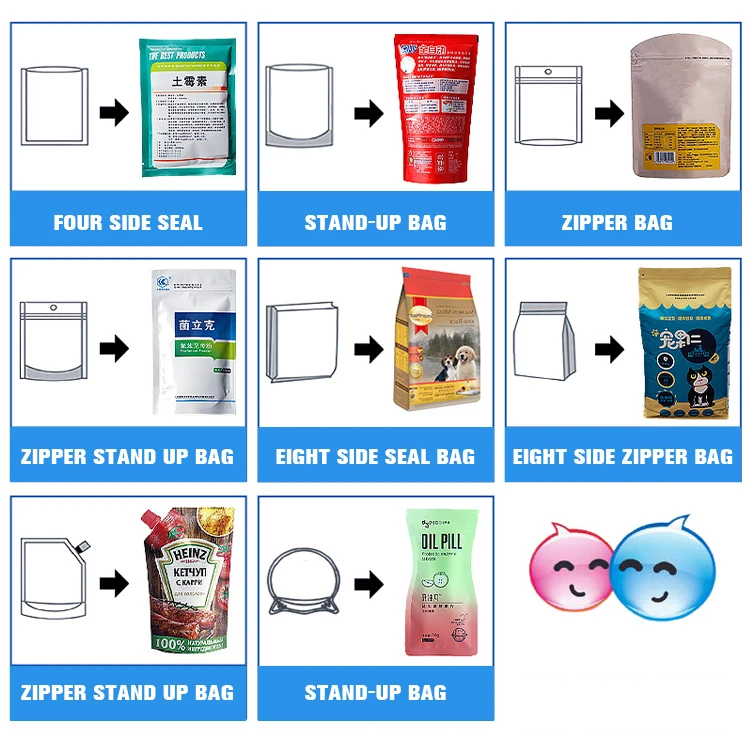

4.Flexibility and Versatility: Multihead packaging machines can handle a wide range of product types, sizes, and weights. They offer flexibility in adjusting packaging parameters, such as filling quantities and packaging formats, to accommodate various packaging requirements. This versatility makes them suitable for diverse industries and product applications.

5.Improved Packaging Quality: These machines provide consistent and precise packaging, ensuring that each package is filled accurately and sealed properly. This helps maintain product freshness, extend shelf life, and enhance overall packaging quality. It also reduces the risk of product spillage, contamination, or damage during transportation.

What products are suitable for packaging with fully automatic multihead packaging machine?

Fully automatic multihead packaging machines are suitable for packaging a wide range of products, including:

Dry Food Products: These machines are commonly used for packaging dry food products such as rice, cereals, pasta, beans, nuts, snacks, spices, coffee beans, and powdered ingredients.

Confectionery and Bakery Items: Multihead packaging machines can efficiently package confectionery items like candies, chocolates, toffees, gummies, and bakery products such as cookies, biscuits, and pastries.

Frozen Foods: These machines can handle frozen food products like frozen fruits, vegetables, seafood, meatballs, and other frozen food items, ensuring efficient and hygienic packaging.

Pet Food: Multihead packaging machines are suitable for packaging various types of pet food, including dry kibble, treats, and snacks for cats, dogs, and other pets.

Non-Food Granular Products: They can also be used for packaging non-food granular products such as detergents, cleaning agents, fertilizers, chemical powders, pharmaceuticals, and health supplements.

Hardware and Fasteners: Fully automatic multihead packaging machines are capable of packaging small hardware items like screws, bolts, nuts, washers, and fasteners, ensuring accurate counts and efficient packaging.

Small Parts and Components: They are suitable for packaging small parts and components used in industries like electronics, automotive, toys, and hardware, ensuring precise counting and packaging.

Fully automatic multihead packaging machines offer several advantages, including high-speed operation, precise weight control, consistent packaging quality, and increased production efficiency. They are widely used in industries that require fast and accurate weighing and packaging of a variety of products, such as snacks, confectionery, nuts, grains, and more.