What is a fully automatic multihead packaging machine?

Fully automatic multihead packaging machine is an advanced packaging equipment that combines the functions of a multihead weigher with automated operations. It is designed to streamline the packaging process, minimize human intervention, and maximize efficiency.

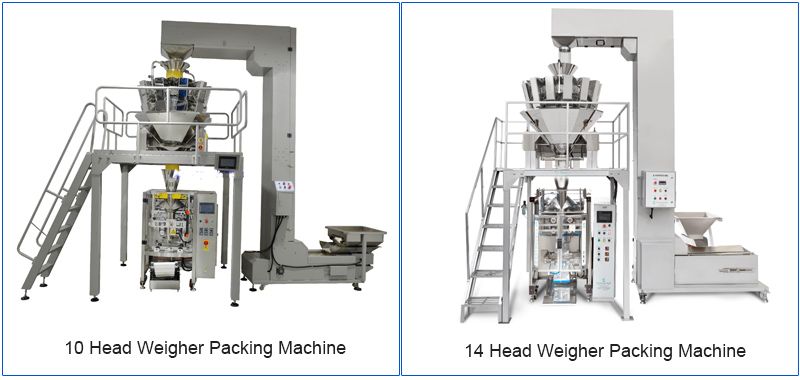

Types of fully automatic multihead packaging machine

The common combination weigher includes ten head weigher and fourteen head weigher. Besides, we supply double-head weigher packing machines and four-head weigher packaging machines as well. You also can customize the machine according to your needs.

Live Video

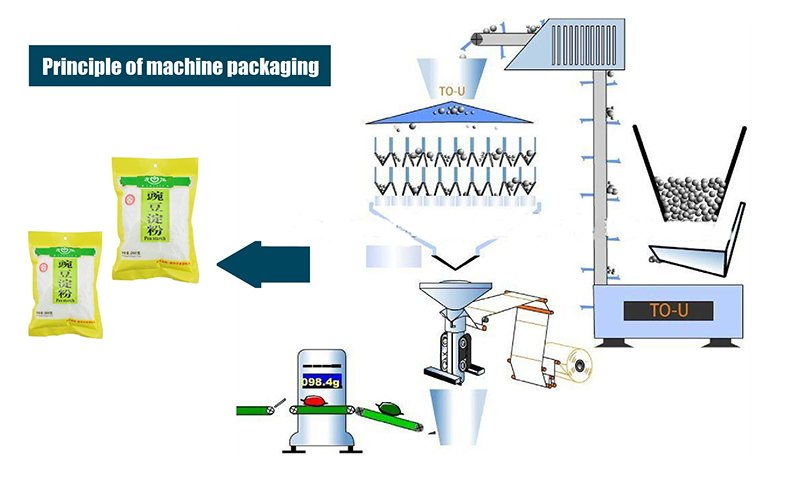

How does fully automatic multihead packaging machine work?

The fully automatic multihead packaging machine is a cutting-edge technology designed to streamline the packaging process with efficiency and precision. This advanced machine employs a combination of sophisticated sensors, actuators, and intelligent software to automate the entire packaging workflow. With multiple heads, it can simultaneously handle various packaging tasks, such as weighing, filling, sealing, and labeling. The machine's sensors accurately detect the product's weight and volume, ensuring precise measurements for each package. Its automated arms swiftly and accurately pick up the products and place them into the designated containers. The machine's intelligent software optimizes the packaging sequence, minimizing downtime and maximizing throughput. With its seamless integration and smooth operation, the fully automatic multihead packaging machine revolutionizes packaging processes across industries, delivering consistent quality, increased productivity, and significant time savings.

Fully automatic multihead packaging machine specifications

| Type | TH420 | TH520 | TH720 |

| Bag length | 80-300mm | 80-400mm | 100-400mm |

| Bag width | 50-200mm | 80-250mm | 180-350mm |

| Max width of roll film | 420mm | 520mm | 720mm |

| Packing speed | 5-30bags/min | 5-50bags/min | 5-50bags/min |

| Air consumption | 0.65mpa | 0.65mpa | 0.65mpa |

| Gas consumption | 0.3m³/min | 0.4m³/min | 0.4m³/min |

| Power voltage | 220V | 220VAC/50HZ | 220VAC/50HZ |

| Dimension | (L)1320*(W)950*(H)1360 | (L)1150×(W)1795×(H)1650mm | (L)1780×(W)1350×(H)1950mm |

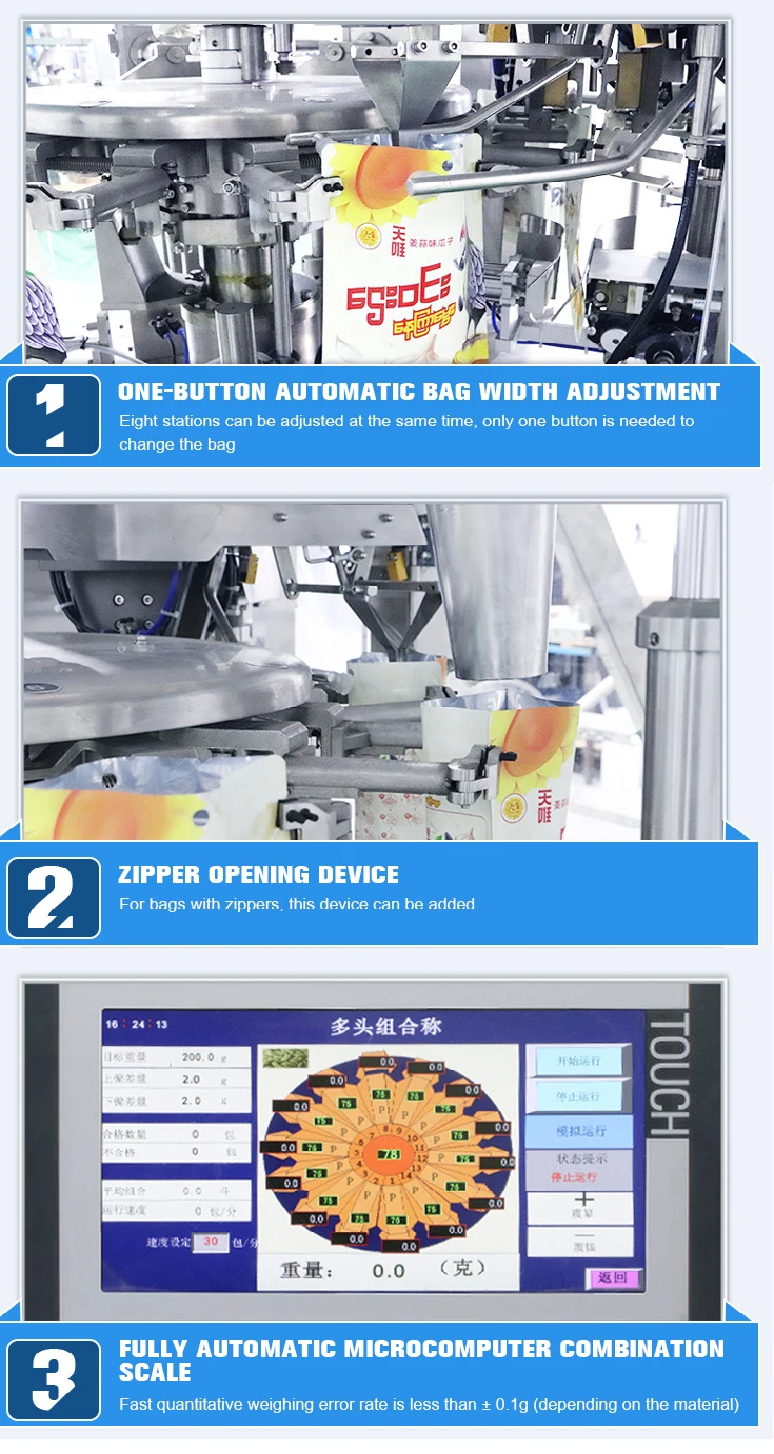

Features of fully automatic multihead packaging machine

As a highly efficient packaging equipment, the fully automatic multi-head packaging machine is often used in food, chemicals, pharmaceuticals and other industries. It uses its own characteristics to become an indispensable and important equipment in modern production lines. The following are some of the characteristics of the fully automatic multi-head packaging machine:

1. Multiple Heads: The packaging machine features multiple heads, allowing it to fill and seal multiple packages simultaneously. This significantly increases packaging speed and efficiency.

2. Versatility: Fully automatic multihead packaging machines are highly versatile and can handle a wide range of products. They are suitable for packaging solids, liquids, powders, and granules in various shapes and sizes.

3. High Speed: With multiple heads operating simultaneously, these machines achieve high packaging speeds. This is especially beneficial for large-scale production environments where a significant volume of products needs to be packaged quickly and efficiently.

4. Adjustable Packaging Parameters: The machine allows for adjustments to packaging parameters, such as the fill weight, bag size, and sealing temperature. This flexibility enables manufacturers to customize the packaging process to match the specific requirements of their products.

5. Easy Maintenance and Cleaning: The fully automatic multihead packaging machine is designed for ease of maintenance and cleaning. The modular construction facilitates access to various components for routine maintenance and sanitation procedures.

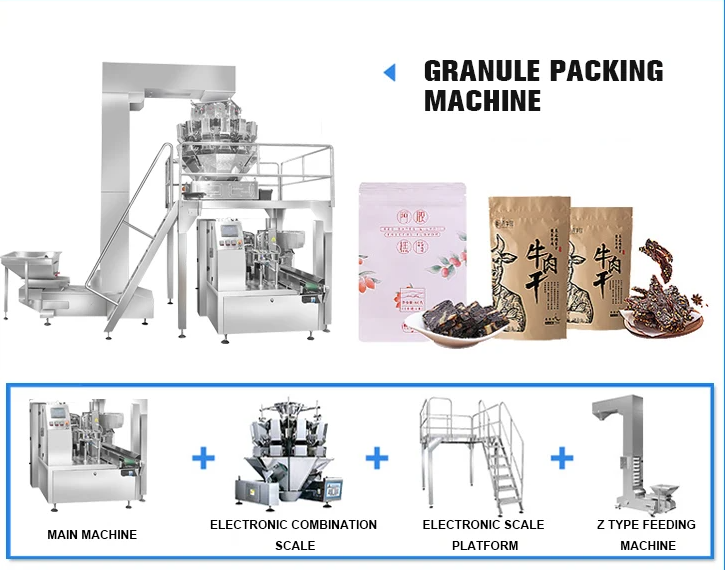

Structure of fully automatic multihead packaging machine

The structural design of the fully automatic multi-head packaging machine is usually carefully optimized. The coordinated operation of each component enables the equipment to meet the packaging needs of different products and provide enterprises with reliable packaging solutions. The following is the main structure of the fully automatic multi-head packaging machine

Weighing Heads: The machine features multiple weighing heads, corresponding to the number of hoppers. Each weighing head contains a load cell or weighing sensor to measure the weight of the product in the respective hopper accurately.

Computerized Control System: A sophisticated computerized control system is at the heart of a fully automatic multihead packaging machine. This system allows operators to set and adjust various parameters, such as target weights, timing, packaging configurations, and operating modes. It also provides real-time monitoring and control over the packaging process.

Distribution System: The machine employs an automated distribution system to transport the weighed product from the hoppers to individual packaging units. This system can include conveyors, chutes, or other mechanisms for precise and efficient product transfer.

Packaging Unit: A fully automatic multihead packaging machine is typically equipped with a packaging unit, such as a form-fill-seal machine. This unit automatically forms the packaging material, fills it with the weighed product, and seals it, creating a complete package.

What are the applications of fully automatic multihead packaging machine?

The flexibility and applicability of the fully automatic multi-head packaging machine enable it to meet the diverse packaging needs of different industries. The following are some common applications of fully automatic multi-head packaging machines:

Food Industry: The multihead packaging machine is extensively used in the food industry for packaging items like snacks, cereals, nuts, candies, frozen foods, and more. Its ability to accurately weigh and fill products ensures consistent portion sizes, while its sealing and labeling capabilities maintain product freshness and brand integrity.

Pharmaceutical Industry: In the pharmaceutical sector, the machine plays a crucial role in packaging tablets, capsules, and other medications. Its precise filling and sealing mechanisms ensure accurate dosages and maintain the integrity of the drugs, adhering to strict quality standards and regulatory requirements.

Cosmetics and Personal Care Industry: Multihead packaging machines are employed in packaging cosmetics, toiletries, and personal care products. These machines handle various packaging formats like bottles, tubes, jars, and pouches, ensuring efficient and hygienic packaging of items such as lotions, creams, shampoos, and more.

Agriculture and Horticulture: In the agriculture and horticulture sector, the machine is used for packaging items like seeds, grains, nuts, and fruits. It enables efficient weighing, filling, and sealing of these products, ensuring consistent quality and reducing manual labor.

Customer case

A snack manufacturer uses a Fully Automatic Multihead Packaging Machine to pack mixed nuts. The machine can accurately weigh different kinds of nuts, mix them and pack them into small bags; it improves packaging efficiency, ensures the accurate weight of each bag of nuts, and reduces labor costs.

A large candy factory uses a Fully Automatic Multihead Packaging Machine to pack various candies. The machine can run at high speed, meeting the large-scale production needs of the candy factory; it greatly improves production efficiency, reduces production costs, and ensures the hygienic safety of candy packaging.

A pharmaceutical company uses a Fully Automatic Multihead Packaging Machine to pack tablets and capsules. The machine can accurately count the number of drugs in each bottle or box; it ensures the accuracy of drug packaging, avoids errors in manual counting, and improves packaging efficiency.

A shampoo manufacturer uses a Fully Automatic Multihead Packaging Machine to fill shampoo. The machine can accurately control the filling volume of each bottle; it improves filling accuracy, reduces raw material waste, and ensures product quality.

Fully automatic multihead packaging machine in the factory

We are a professional manufacturer dedicated to providing advanced packaging machinery and equipment, with many years of rich industry experience and technical strength. Our products cover fully automatic multi-head packaging machines, single-head packaging machines, conveying equipment, etc., which are widely used in many industries such as food, medicine, cosmetics, daily chemical products, etc. Our equipment is flexible and diverse in design, and can be applied to product packaging of different specifications and shapes to meet the different needs of customers. The price of our products varies according to the model, configuration and the degree of customization required by customers. Generally between $790.00-$12,600.00. In order to meet the needs of different customers, we provide flexible price plans and customized services. If you are interested in fully automatic multi-head packaging machines or have any packaging equipment needs, please feel free to contact our sales team. We will wholeheartedly provide you with professional consulting services and tailor the most suitable packaging solutions for you. Looking forward to working with you!