What is an economic linear weigher with a vertical packaging machine?

Economic linear weigher with a vertical packaging machine is an automated packaging system that enables efficient and accurate filling and packaging of various products into vertical packages. This system is commonly used in industries such as food, beverages, pharmaceuticals, cosmetics, and consumer goods.

How does economic linear weigher with a vertical packaging machine work?

A double feeding vertical packaging system simultaneously handles two different products by feeding them into separate filling systems. The packaging material forms a vertical tube, and the two products are dispensed into the bag through their respective filling mechanisms. The bag is sealed, separated, and discharged for further processing. This system streamlines the packaging process, improves efficiency, and allows for simultaneous packaging of different products into separate bags.

Features of economic linear weigher with a vertical packaging machine

Efficiency: The linear weigher ensures accurate and consistent product weighing, which leads to precise filling of packages. This helps minimize product giveaway and reduces material waste.

Speed: The combination of the linear weigher and vertical packaging machine allows for high-speed packaging operations. The linear weigher can quickly dispense the correct weight of product, and the vertical packaging machine can efficiently form and seal packages at a rapid pace.

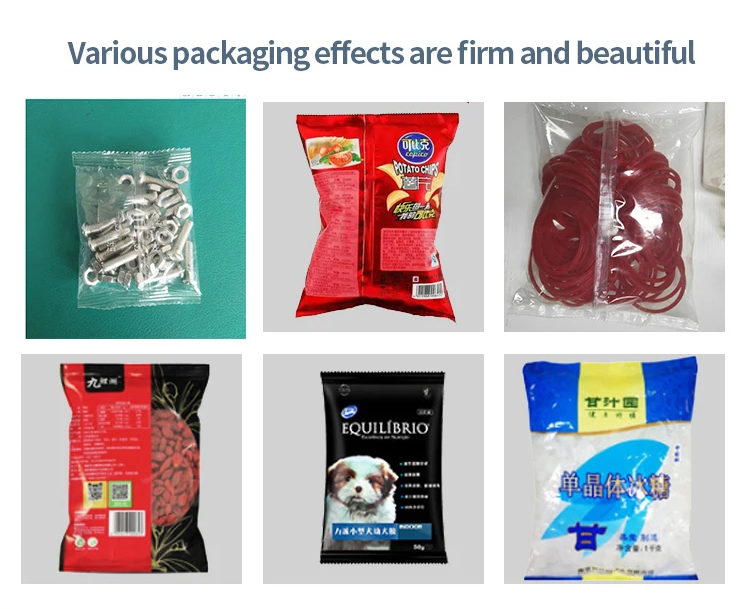

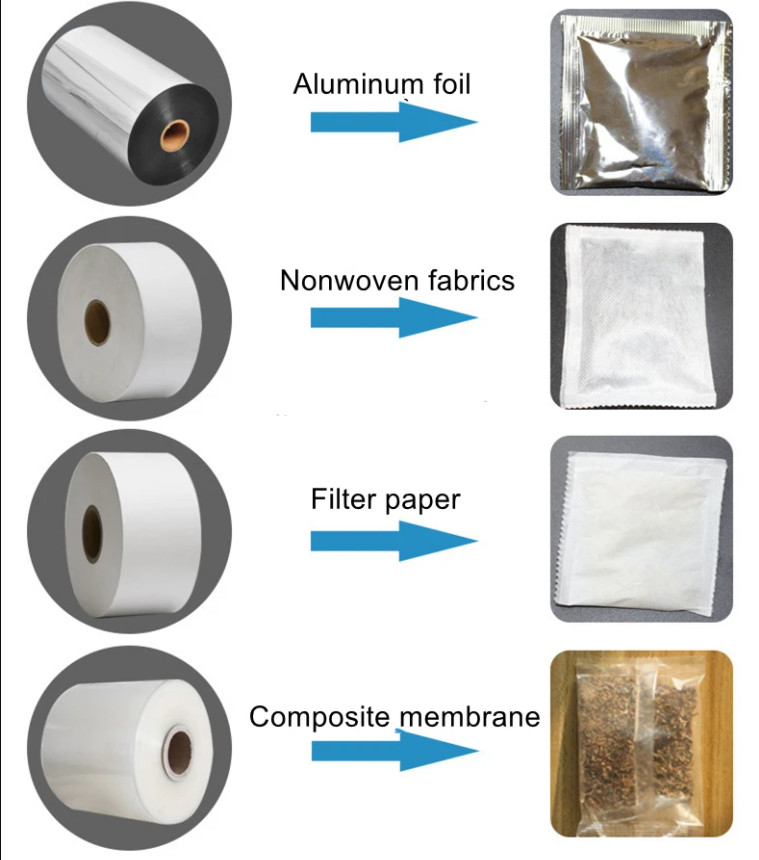

Versatility: The system is versatile and can handle a wide range of products, such as snacks, grains, nuts, coffee, and more. The linear weigher can be adjusted to accommodate different product weights and sizes, while the vertical packaging machine can handle various bag sizes and styles.

Cost-effectiveness: The economic linear weigher is designed to provide a cost-effective weighing solution, making it suitable for small to medium-sized production facilities. The combination of the linear weigher and vertical packaging machine helps optimize packaging efficiency and reduce labor costs.

Economic linear weigher with a vertical packaging machine specifications

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 0KG | 94KG | 101KG |

Structure of economic linear weigher with a vertical packaging machine

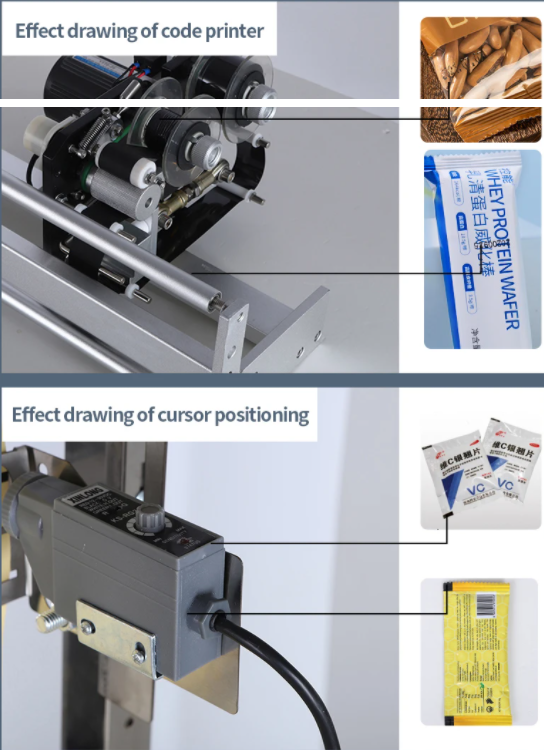

An economic linear weigher with a vertical packaging machine is a packaging system that combines a weighing component with a vertical form-fill-seal (VFFS) machine. The linear weigher consists of multiple weighing heads connected to load cells, which accurately measure the desired quantity of the product. The vertical packaging machine forms, fills, and seals flexible packaging bags. The weighed product is automatically transferred from the linear weigher to the filling system of the vertical packaging machine. The filling system dispenses the product into the formed bags, which are then sealed for packaging. This integrated system offers efficiency, versatility, and automation in weighing and packaging operations.

What are the applications of economic linear weigher with a vertical packaging machine?

The economic linear weigher with a vertical packaging machine is widely used in various industries for efficient and accurate weighing and packaging operations. It finds applications in food packaging, including snacks, nuts, candies, grains, and other small to medium-sized food items. Additionally, it is also utilized in non-food industries for packaging items such as hardware components, pharmaceuticals, chemicals, and more. The integrated system offers versatility in handling different product types, ensuring precise weighing, and automating the packaging process, making it a valuable solution for a wide range of packaging applications.

Customer case

| Customer Background | Solutions | Customer Feedback |

| A food processing factory needs to accurately weigh and package a variety of snacks (such as potato chips and nuts). Traditional manual operations are inefficient and have large errors. | The combination of an economical linear weighing machine and a vertical packaging machine is used to achieve automated weighing and packaging. The linear weighing machine can process 400 bags per hour with a weighing accuracy of ±0.5 grams. | Production efficiency increased by 50% and labor costs decreased by 30%. ; Packaging accuracy improved, reducing material waste. |

| A feed factory needs to accurately weigh feed pellets and pack them into small bags. Traditional equipment is inefficient and easy to clog. | Introducing a combination of a linear weighing machine and a vertical packaging machine, which can process 200 bags per hour, suitable for granular materials | Production efficiency increased by 40%, and the packaging speed reached 15-40 bags/minute; the equipment operates stably, with a low failure rate and reduced maintenance costs. |

| A chemical company needs to accurately weigh and package granular raw materials (such as plastic pellets), but traditional equipment is not accurate enough. | The combination of high-precision linear weighing machine and vertical packaging machine has a weighing accuracy of ±0.2 grams, which is suitable for fine chemical raw materials. | The weighing accuracy is improved, and the waste of raw materials is reduced by 20%; the degree of automation is high, which reduces manual intervention. |

| A company specializing in nut processing, its products include peanuts, almonds, cashews, etc. | Nut particles are irregular, and traditional packaging equipment is prone to jamming, affecting production efficiency; a high-precision weighing system is required to ensure the consistent weight of each bag of product. | The dual-channel vertical packaging system is introduced, equipped with anti-jamming design and high-speed weighing module to ensure smooth transportation and accurate weighing of nut particles. |

| A pet food manufacturer, mainly producing granular foods such as dog food and cat food. | Pet food particles are large, and traditional packaging equipment fills unevenly, affecting the appearance of the product; a high-capacity packaging system is required to meet the growing market demand. | A dual-channel vertical packaging system is used, equipped with a large-capacity hopper and a high-speed filling device to ensure uniform filling and efficient packaging of pet food. |