What is rotary premade bag packing machine for powder?

Rotary premade bag packing machine for powder is a specialized packaging machine that is designed to fill and seal pre-formed bags with powdered products. It is commonly used in industries such as food, beverage, pharmaceuticals, personal care, home products, industrial chemicals, and pet food.

Using a rotary premade bag packing machine for powder provides numerous benefits, including efficient and precise filling, high-speed operation, reliable sealing, user-friendly interface, product safety, and the ability to package a variety of powdered products. It helps businesses streamline their packaging processes, improve productivity, ensure product quality, and meet the demands of the market.

What Types of Rotary Premade Bag Packing Machine For Powder are there?

When choosing a powder rotary pre-made bag packaging machine, you can consider production needs, packaging materials, degree of automation, flexibility and other aspects to choose the most suitable packaging machine. The following are several of the most commonly used packaging machine types:

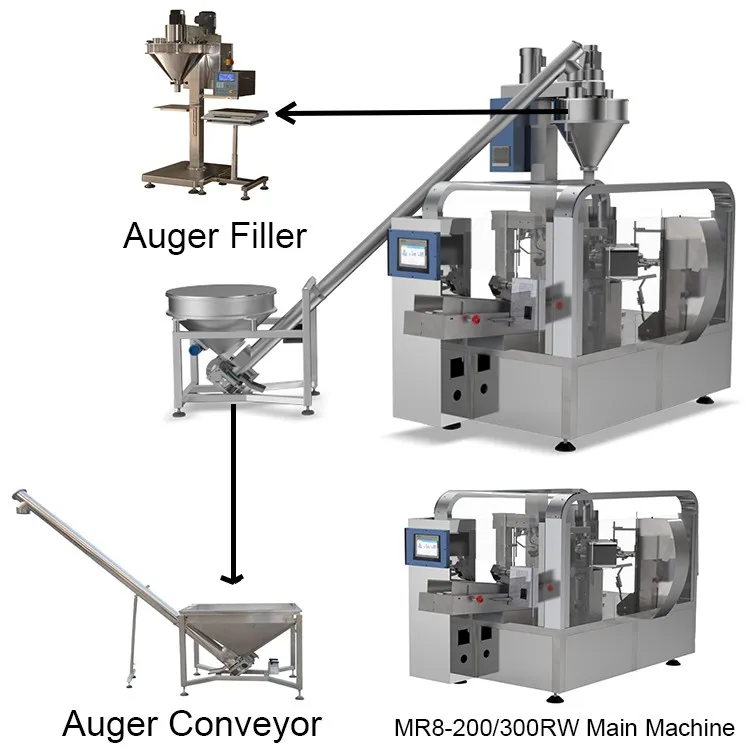

Rotary auger filling machine: This type of machine uses an auger to measure the powder product and dispense it into pre-made bags. The auger rotates to accurately fill the required amount of powder into the bag.

Rotary combination weighing machine: This type of machine combines weighing and filling mechanisms to accurately dispense powder products into pre-made bags. It utilizes multiple weighing scales to achieve precise and efficient filling.

Vertical powder rotary pre-made bag packaging machine: It is a packaging machine designed in a vertical form, suitable for small to medium-sized production needs, with high packaging efficiency and accurate metering accuracy.

Horizontal powder rotary pre-made bag packaging machine: It is a packaging machine designed in a horizontal form. Compared with the vertical design, the horizontal packaging machine is generally more suitable for large-scale production needs, and generally has a higher packaging speed and greater packaging capacity.

How does rotary premade bag packing machine for powder works?

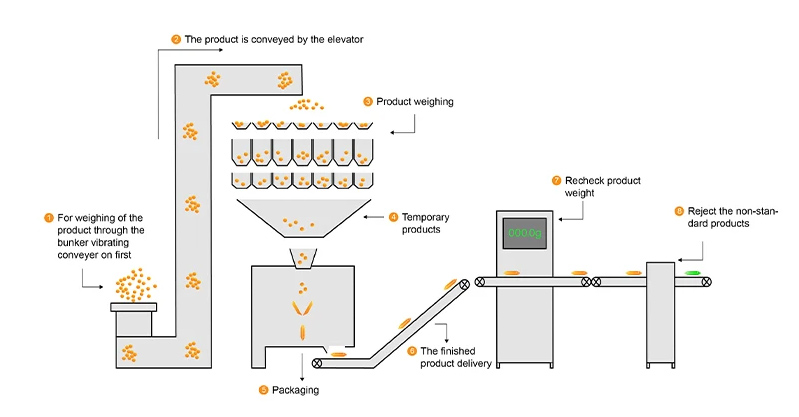

Rotary premade bag packing machines for powder operate through a multi-station rotary system that efficiently handles the entire packaging process. The system begins by automatically loading premade bags onto the rotary platform, which then sequentially moves them through various workstations. At the filling station, precise dosing mechanisms - including augers or volumetric fillers - accurately measure and dispense the powdered product into each bag. The filled bags then advance to the sealing station where heat or pressure creates an airtight seal, with optional nitrogen flushing available for enhanced product preservation. Finally, the completed packages are automatically discharged from the machine, ready for distribution. This continuous rotary motion design ensures high-speed, consistent packaging while maintaining product quality and accuracy.

What are the applications of rotary premade bag packing machine for powder?

Rotary premade bag packing machine for powder is used to pack various powder products. Here are some common powder types that can be packaged by rotary premade bag powder packaging machines:

Food powder: such as flour, milk powder, cocoa powder, coffee powder, condiments, protein powder, spices, etc.

Cosmetic powder: such as foundation, loose powder, eye shadow, blush, powdery mask, etc.

Pharmaceutical powder: such as medicinal powder, traditional Chinese medicine powder, health product powder, etc.

Chemical product powder: such as dyes, pigments, catalysts, additives, etc.

Agricultural fertilizer powder: such as nitrogen fertilizer, phosphate fertilizer, potassium fertilizer, etc.

Building material powder: such as cement, gypsum, lime powder, etc.

Customer site

What are the advantages of rotary premade bag packing machine for powder?

As a common automated packaging equipment, the powder rotary pre-made bag packaging machine is one of the important equipment for many powder product manufacturers to improve packaging efficiency and product quality. It uses the following features to provide an efficient, accurate and reliable solution for the packaging of powder products.

Increased Efficiency: The rotary design and multiple filling stations significantly improve packaging efficiency, allowing for high-speed production lines and increased output.

Accurate Filling: The precise filling system ensures consistent and accurate filling weights, minimizing product giveaway and maintaining product quality.

Reliable Sealing: The advanced sealing mechanism ensures secure and airtight seals, preventing product contamination and preserving product freshness.

Versatile Packaging: The machine's compatibility with a wide range of premade bags and its ability to handle various bag sizes and styles make it a versatile solution for diverse packaging needs.

Easy Operation: The intuitive control panel simplifies operation and allows for quick adjustments of packaging parameters, making it accessible to operators of all skill levels.

Durable Construction: The robust construction of the machine ensures longevity and reliability, reducing maintenance costs and downtime.

Rotary premade bag packing machine for powder specifications

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

Structure of rotary premade bag packing machine for powder

The structure of a rotary premade bag packing machine for powder typically consists of a rotary system with multiple stations. It includes a bag loading station where premade bags are loaded onto the machine. The bags are then transported to the filling station where a precise amount of powder is dispensed into each bag. Next, the bags move to the sealing station where heat or pressure is applied to seal the bags securely. Optional features like nitrogen flushing may be included for extended product shelf life. Finally, the filled and sealed bags are discharged from the machine for further processing or distribution. The machine's design ensures efficient and automated packaging of powdered products in premade bags.

Customer case

| Application Scenario | Packaging Capacity | Packaging Speed | Packaging Size |

| A food company in Pakistan packages starch for the retail market | 500g/bag | 40-50 bags/minute | 150-200mm wide, 200-250mm long |

| A condiment factory in the United States packages condiment powder (such as pepper and chili powder) and supplies it to restaurant chains | 20g/bag | 60-80 bags/minute | 100-200mm wide, 100-300mm long |

| A French agrochemical company packages pesticide powder to ensure moisture-proof sealing | 1kg/bag | 30-40 bags/minute | 180-250mm wide, 250-350mm long |

How to choose a rotary premade bag packing machine for powder?

| Consideration factors | Analysis dimensions | Detailed description | Select a suggestion |

| Powder characteristics | Flowability | Powders with good flowability (such as sugar) and powders with poor flowability (such as flour) have different requirements for packaging machines. | Powders with good flowability: best suited for auger filling (high speed, ±1% accuracy). Powders with poor flowability: need to choose a metering device with vibration or stirring function to ensure accurate metering. |

| Dustiness | Powders with high dustiness (such as milk powder) are easy to pollute equipment and the environment. | Choose a packaging machine with a dust removal device or good sealing. | |

| Viscosity | Powders with high viscosity (such as some food additives) are easy to clog the metering device. | Choose a metering device with an anti-stick coating or one that is easy to clean. | |

| Packaging volume | Small bags | Packaging volume 5-100g | High-speed combination weighing machine (60-100 bags/minute), e.g. spices, instant coffee. |

| Medium bag | Packing volume 100g-1kg | Spiral filler (30-60 bags/minute), e.g. protein powder, flour | |

| Big bag | Packing volume 1kg-25kg | Weight filling (10-30 bags/minute), e.g. fertilizer, industrial powder. | |

| Packing speed | Low speed (10-30 BPM) | Several bags per minute. | Manual/semi-automatic machines (small batches) |

| Medium speed (30-60 BPM) | Packs dozens of bags per minute. | Standard rotary machines (food/pharmaceutical) | |

| High speed (60-100+ BPM) | Packs hundreds of bags per minute. | Multi-head weighing machine (seasoning, additives) | |

| Packaging size | Small bag | Small bag (50-150mm width) → Vertical machine. | |

| Big bag | Big bag (150-300mm width) → Horizontal machine. | ||

| Packaging bag material | Composite film | Wide application range, such as food, chemical industry, etc. | |

| Aluminum foil bag | Has good barrier properties, suitable for products with high shelf life requirements. | ||

| Paper bag | Environmentally friendly, suitable for some food and chemical products. | ||

How is the price of rotary pre-made bag packaging machine for powder?

The price of a rotary bagging powder packaging machine is affected by many factors, including equipment specifications, production capacity, functional configuration, brand manufacturer, market supply and demand, etc. Generally speaking, the price range is relatively wide, ranging from $600.00 to $14,000.00. If you have specific needs, you can directly contact us and we will provide a detailed quotation based on your packaging materials and packaging bag styles. Of course, if you have other needs, we can also provide customized services.

Why choose us as your rotary premade bag packing machine for powder supplier?

Xinxiang Dahan is a manufacturer specializing in the production of rotary premade bag packing machine for powder. They are committed to developing and manufacturing high-quality, high-efficiency packaging equipment to meet the packaging needs of powder products. Xinxiang Dahan is known for its reliability, innovation and excellent after-sales service, providing customers with comprehensive solutions and support.