How to Select Vertical Form Fill Seal Powder Packaging Machine?

Vertical Form Fill Seal Powder Packaging Machine has three types of feeding: spiral feeding, belt feeding and bucket lifting. You can choose the corresponding equipment according to the type of packaging products and application scenarios.

-

Spiral feed vertical form fill seal powder packaging machine

Applicable materials: fine powder materials (milk powder, seasoning powder, protein powder, pharmaceutical powder, etc.)

Packing speed: 20-100 bags/minute

Packing size range: bag length (80-300mm) * bag width (50-200mm), filling volume 10g-5kg

Packing bag material: composite film (PET/AL/PE), kraft paper, aluminum foil bag

High-precision + dust-proof design: screw metering accuracy reaches ±0.5%-1%, and the fully enclosed structure reduces dust emission

-

Belt feeding vertical form fill seal powder packaging machine

Applicable materials: granular powder with good fluidity (such as sugar, instant coffee, solid beverage granules)

Packing speed: 30-120 bags/minute (linear scale measurement)

Packing size: length (100-400mm) * width (80-300mm), filling volume: 50g-10kg

Packing bag material: woven bag, PE film, stand-up bag (with zipper)

Large capacity + easy to clean: suitable for large packages above 5kg, the belt can be quickly disassembled for cleaning

-

Z-type elevator feeding Vertical Form Fill Seal Powder Packaging Machine

Applicable materials: easy-to-caking powders (such as milk powder, chemical powders), mixed materials (such as seasonings, feed additives)

Packing speed: 15-80 bags/minute

Packing size: length (150-500mm) * width (100-400mm), filling volume: 1-25kg

Packing bag material: paper-plastic composite bag, valve bag, anti-static bag

Anti-bridging + multi-function: Z-shaped lifting bucket avoids material accumulation, compatible with granule/powder mixed packaging

What is vertical form fill seal powder packaging machine?

Vertical form fill seal powder packaging machine is a type of packaging equipment specifically designed to efficiently package powdered products. It incorporates a vertical bagging system that forms, fills, and seals pouches in a continuous vertical motion.

Vertical form fill seal powder packaging machine powder packaging machines streamline the packaging process for powdered products, offering benefits such as high-speed operation, accurate filling, efficient sealing, and reliable packaging quality. They are widely used in various industries, including food, pharmaceuticals, chemicals, and cosmetics, to package a range of powdered products such as spices, coffee, protein powders, flour, and detergent.

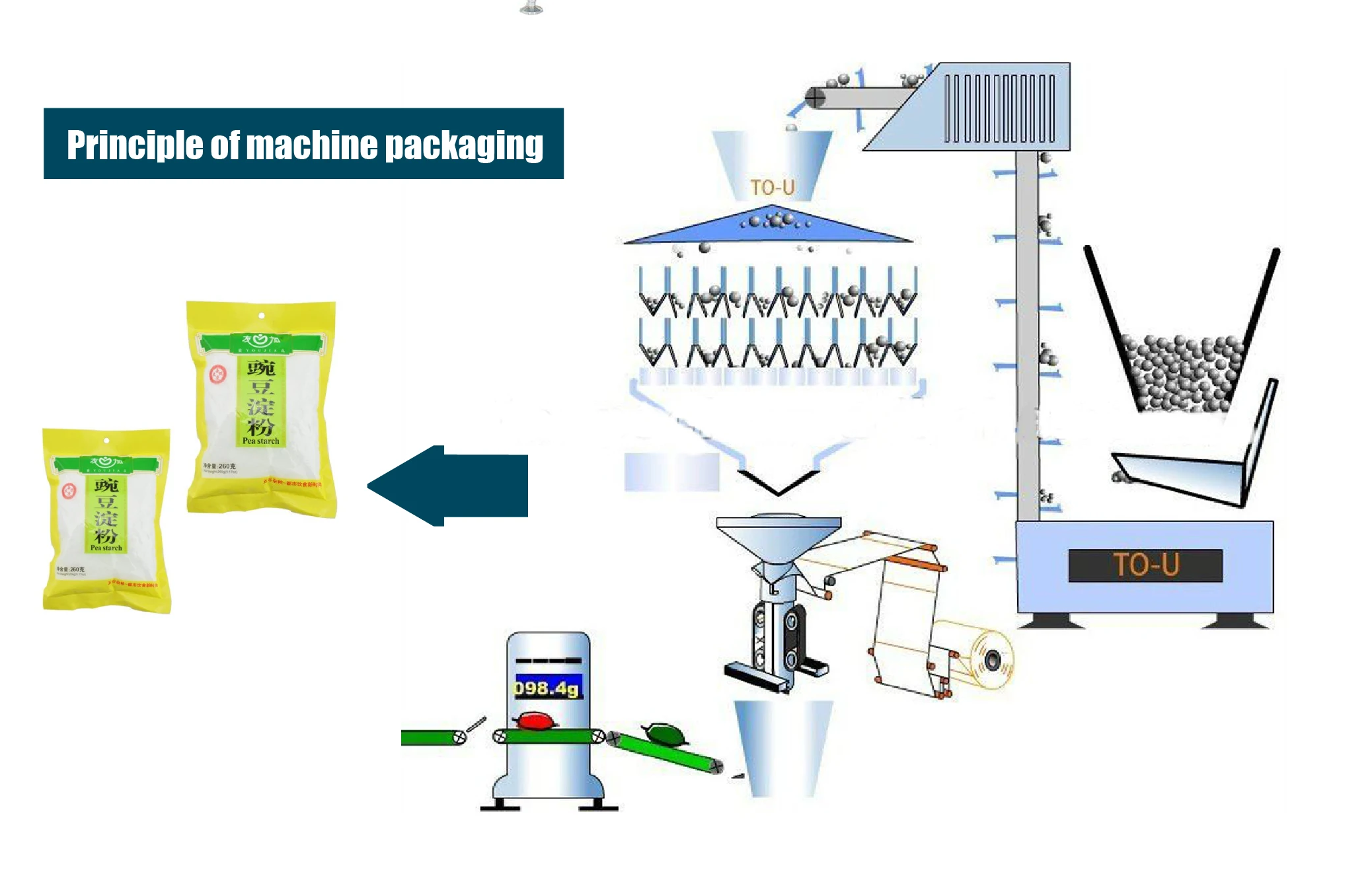

How does vertical form fill seal powder packaging machine works?

Vertical Form Fill Seal Powder Packaging Machine automate the powder packaging process with precision and efficiency. Its operation is controlled by a central system to ensure seamless coordination. Here’s a step-by-step breakdown:

Film Unwinding: Packaging film is unwound from a roll and guided into the machine.

Bag Forming: The film is formed into a vertical tube using a forming ring; the longitudinal edges are heat-sealed to form a continuous bag.

Powder filling: A metering system (auger, volumetric cup, or weigh filler) dispenses a precise amount of powder into the tube.

Horizontal sealing and cutting: Heat-sealing jaws seal the top of the filled bag; a cutting mechanism separates individual bags from the film tube.

Output: The finished bags are discharged onto a conveyor or collection bin for further processing.

What are the applications of vertical form fill seal powder packaging machine?

Vertical fill seal powder packaging machine is specially used to pack various types of powder products and is widely used in the packaging of powder products. The following are some application scenarios of vertical fill seal powder packaging machine:

Food Powders: Spices, seasoning mixes, flour, cocoa powder, powdered sugar, coffee powder, tea powder, protein powder, baking mixes, powdered beverages, etc.

Pharmaceutical Powders: Medicinal powders, powdered supplements, powdered vitamins, herbal powders, powdered medications, etc.

Chemical Powders: Detergent powders, cleaning powders, powdered fertilizers, powdered pesticides, powdered additives, etc.

Cosmetics Powders: Face powders, talcum powders, body powders, powdered cosmetics, powdered masks, etc.

Nutraceutical Powders: Nutritional supplements, powdered health drinks, powdered meal replacements, powdered herbal extracts, etc.

Live video

Features of vertical form fill seal powder packaging machine

The vertical fill and seal powder packaging machine has many advantages and features that make it an ideal choice for powder material packaging. The following are the advantages and features of the vertical fill and seal powder packaging machine:

The use of an automated control system can achieve an efficient packaging process and improve production efficiency.

Equipped with a precise metering device, it can accurately dispense powder materials according to the preset filling amount, ensuring that the filling amount of each packaging bag is consistent and accurate.

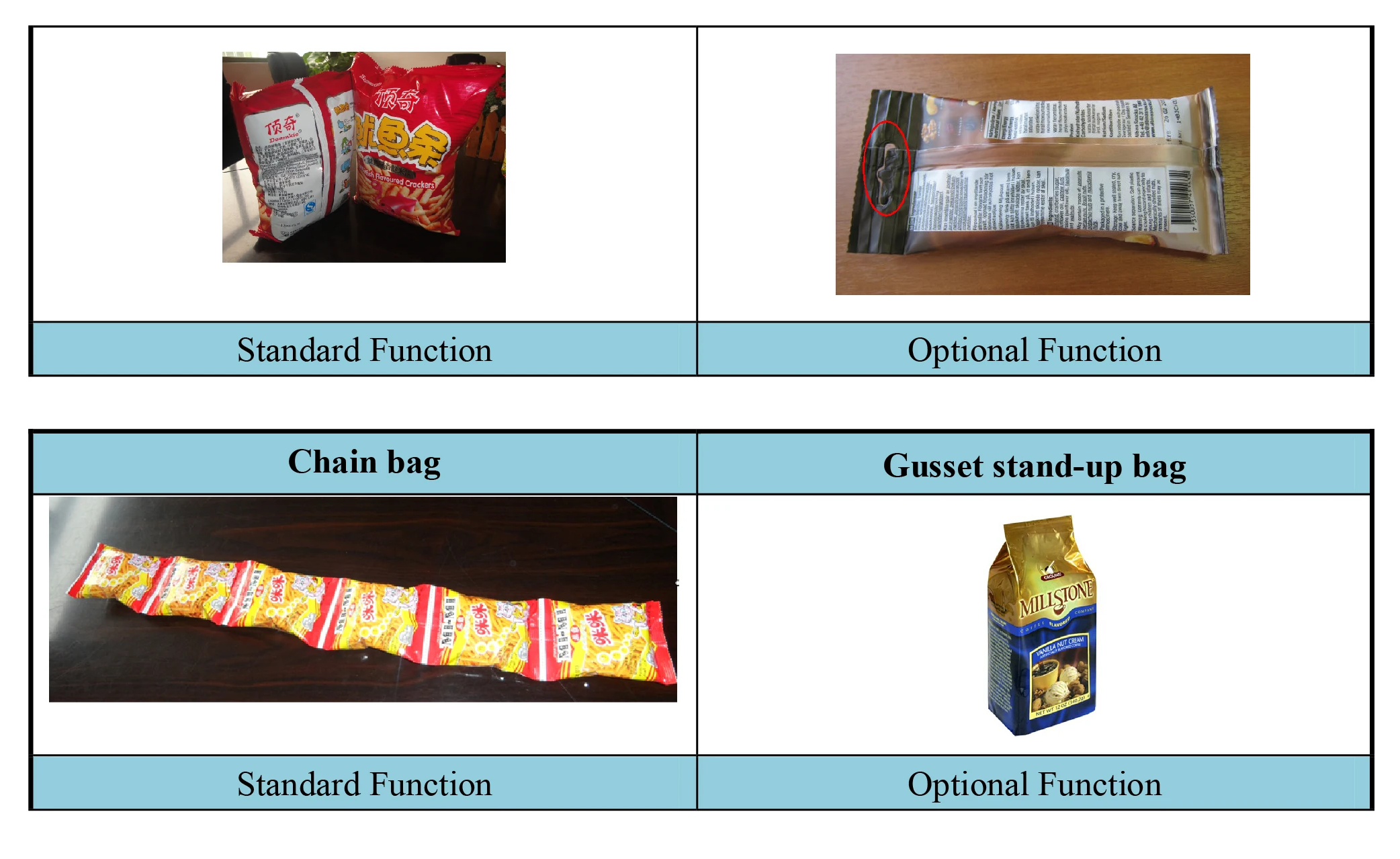

With a variety of functions and configuration options, it can adapt to different packaging needs.

Applicable to various types of powder materials, such as food powder, cosmetic powder, pharmaceutical powder, etc.

Through high-temperature sealing or other sealing technologies, it ensures the sealing and freshness of the packaging bag to prevent leakage and oxidation of powder materials.

Vertical form fill seal powder packaging machine specifications

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

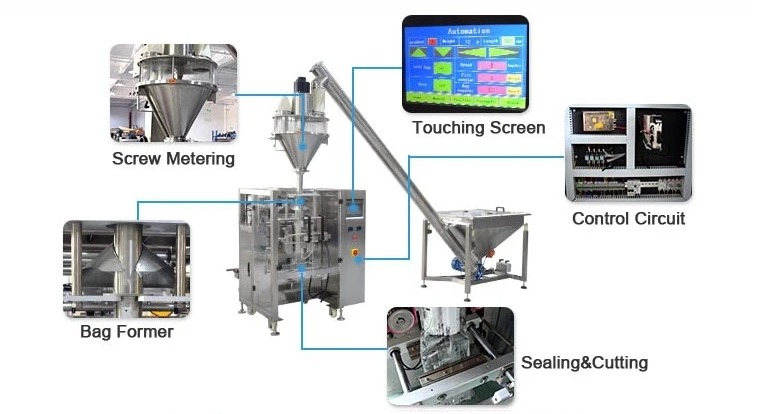

Structure of vertical form fill seal powder packaging machine

Vertical form fill seal powder packaging machineconsists of a film unwinding mechanism, a bag forming unit, a powder filling system, a sealing mechanism, and a cutting/discharge system. This structure allows for the efficient and continuous packaging of powdered products.

Customer case

| Application Scenario | Packaging Capacity | Packaging Size | Packaging Speed |

| A dairy company uses VFFS powder packaging machine for automatic packaging of infant milk powder | 5kg/bag (suitable for large-size family-sized milk powder) | Width 180-200mm × length 300-350mm, using four-side sealing (Quad Seal) design to ensure sealing | 30 bags/minute |

| A coffee processing factory uses a fully automatic VFFS packaging machine to package instant coffee powder. | 25g/bag (single brewing quantity) | Width 80-100mm × length 120-150mm, producing pillow bags (Pillow Bag), with easy-tear design | 60 bags/minute |

| A pharmaceutical company uses VFFS packaging machine to pack antibiotic powder | 10g/bag (precise dosage) | Width 50-80mm × length 80-120mm, using 3-Side Seal aluminum foil composite film packaging | 40 bags/minute |

Why choose us as your vertical form fill seal powder packaging machine supplier?

Xinxiang Dahan is a professional manufacturer of vertical form fill seal powder packaging machine. We have significant advantages in this field. Known for its high-quality equipment and superior technology, the company provides comprehensive solutions to meet customers' packaging needs for powder products. Xinxiang Dahan's vertical form fill seal powder packaging machine has high efficiency, accuracy and reliability, and can adapt to the packaging requirements of various powder products. They are committed to continuous innovation and improvement, providing advanced automation features and user-friendly interfaces to increase production efficiency and operational convenience. Xinxiang Dahan focuses on customer satisfaction and provides quality after-sales service and technical support to ensure customers receive excellent performance and reliability when using their equipment.