What is an automatic big open mouth bag packaging machine?

Automatic big open mouth bag packaging machine is a specialized machinery used for efficiently and automatically packaging large-sized products into open mouth bags. The machine is designed to handle products that cannot be easily packaged using traditional methods due to their size or bulkiness.

Automatic Big Open Mouth Bag Packaging Machines play a crucial role in optimizing the packaging process in various industries, offering high speeds, precision, and versatility for efficient and reliable packaging operations.

Supply different types of fully automatic large open bag packaging machines

Automatic large open-mouth bag packaging machines (also known as VFFS packaging machines) can be divided into the following categories according to the handling weight:

Small automatic large open-mouth bag packaging machines: The handling weight range is usually between 5-50 kg, suitable for packaging small or medium batches of products, such as food, feed, chemicals, etc. This type of machine is usually compact, relatively cheap, and easy to operate and maintain.

Medium-sized automatic large open-mouth bag packaging machines: The handling weight range is usually between 50-100 kg, suitable for packaging medium batches of products, such as grain, building materials, minerals, etc. This type of machine usually has higher production efficiency and stronger reliability.

Large automatic large open-mouth bag packaging machines: The handling weight range is usually above 100 kg, suitable for packaging large batches of products, such as cement, fertilizers, steel, etc. This type of machine usually has a strong structure and a high degree of automation, which can meet the needs of high-intensity production operations.

Live Video

How does automatic big open mouth bag packaging machine works?

Bag Feeding: The machine continuously feeds open mouth bags into the packaging area, ensuring a steady supply for filling.

Product Loading: The large-sized products are loaded into the machine, either manually or through a feeding system. The machine may utilize conveyors, augers, or other mechanisms to facilitate the efficient and precise loading of the products into the bags.

Bag Opening and Holding: The machine opens the mouth of each bag and holds it in place using specialized mechanisms. This ensures that the bag remains open and stable during the filling process.

Filling and Metering: The machine dispenses the desired amount of product into each bag. It may employ weighing or metering systems to ensure accurate and consistent filling, depending on the specific requirements of the product.

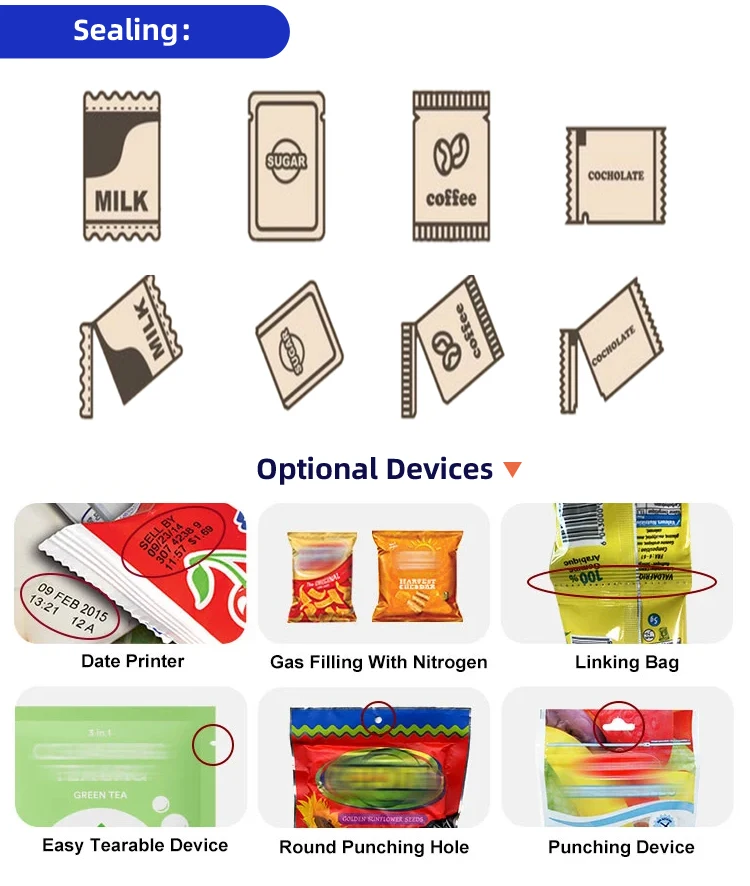

Sealing and Closing: Once the bag is filled, the machine proceeds to seal and close it securely. This may involve heat sealing, stitching, or other methods based on the bag material and desired level of product protection.

What are the characteristics of automatic big open mouth bag packaging machine?

What are the characteristics of fully automatic large open bag packaging machine

Fully automated: The fully automatic large open bag packaging machine uses advanced automation technology, which can realize the automation of the entire packaging process and reduce manual intervention.

Large bag adaptability: This packaging machine is specially designed to handle large bags or large bags of materials, such as heavy granules, powdered materials, bulk materials, etc. It can handle the packaging needs of large bags of materials, such as plastic woven bags, paper bags, polypropylene bags, etc.

Versatility: The fully automatic large open bag packaging machine usually has multiple functions and adjustable parameters to adapt to different materials and packaging requirements. It can realize the adjustment of metering accuracy, the adjustment of packaging speed, the selection of sealing methods, etc.

System integration: The fully automatic large open bag packaging machine is usually integrated and integrated with other production line equipment, such as conveyors, storage silos, automatic control systems, etc.

Automatic big open mouth bag packaging machine specifications

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

When choosing an automatic big open mouth bag packaging machine, consider factors such as the size and weight range of the bags, the type of product being packaged, the required filling capacity, and the specific sealing and methods needed. It is important to select a machine from a reputable manufacturer that offers reliable performance, after-sales support, and customization options to meet your specific packaging needs.

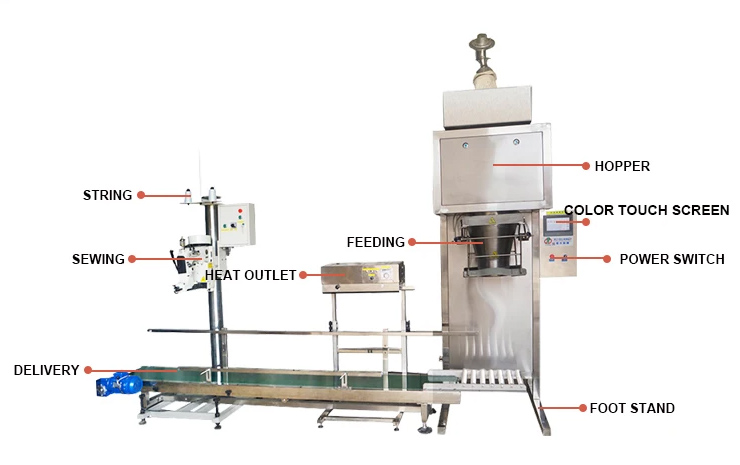

Structure of automatic big open mouth bag packaging machine

Bag Handling: The machine is equipped with a bag feeding system that can handle large open-mouth bags, typically ranging in size from 10 kg to several hundred kilograms. It can accommodate various bag materials, such as woven polypropylene (PP) bags or paper bags.

Filling Mechanism: The machine features a filling mechanism that accurately dispenses the product into the open-mouth bags. This can include a gravity-fed system, auger filler, or a combination of multiple filling technologies, depending on the characteristics of the product being packaged.

Bag Opening and Sealing: The machine automatically opens the bags, typically using mechanical or pneumatic mechanisms, and securely seals them after filling. This ensures proper closure and prevents product spillage or contamination.

Weighing and Dosing: Some machines incorporate weighing scales or load cells to ensure precise filling of the desired weight or volume. This allows for accurate dosing and helps maintain consistent packaging quality.

What are the application scenarios of the fully automatic large open bag packaging machine?

Agriculture: This machine is used for packaging large quantities of agricultural products such as grains, seeds, fertilizers, animal feed, and pet food.

Chemicals: It is employed in the chemical industry for packaging chemicals, powders, granules, and other bulk materials.

Minerals: The machine is used to package minerals, ores, aggregates, sand, cement, and other construction materials.

Food and Beverage: It finds application in packaging large-sized food products such as rice, flour, sugar, salt, coffee beans, and other dry goods.

Pharmaceuticals: The machine is utilized for packaging pharmaceutical powders, tablets, capsules, and other bulk pharmaceutical products.

Construction Materials: It is used for packaging construction materials like cement, concrete mix, drywall compounds, and insulation materials.

Pet Care: The machine is employed in the pet care industry for packaging pet litter, pet food, birdseed, and other pet-related products.

Customer case

| Packaging Case | Customer Background | Customer Question | Solution | Customer feedback |

| A cement plant in Pakistan | This is a large-scale cement production enterprise with an annual output of millions of tons, mainly producing bagged cement. Due to the heavy cement particles and high packaging precision requirements, the customer has been looking for more efficient and more automated packaging equipment. | The original manual packaging equipment not only had low production efficiency, but also caused serious cement dust overflow, resulting in unnecessary waste and environmental pollution. The customer needed an automated equipment that could significantly improve packaging efficiency and reduce dust emissions. | We provide customers with an automatic big open mouth bag packaging machine manufacturers, this equipment is particularly suitable for the packaging of heavy materials, and is designed with an efficient dust removal system to effectively reduce the emission of cement dust. | The automation level of the equipment has increased by 80%, greatly reducing the reliance on manual packaging; the packaging accuracy and sealing have been improved, reducing cement waste; the dust problem has been effectively solved, the working environment is cleaner, and production efficiency has increased by 30%. |

| A fertilizer plant in Myanmar | The fertilizer plant produces a variety of chemical fertilizers, including compound fertilizers, single fertilizers, etc. Due to the wide variety of fertilizer products and the large demand for packaging, the customer needs a flexible and efficient packaging equipment to meet the needs of rapid production and packaging. | Fertilizer granules come in different types and sizes, and some fertilizer granules are relatively large. Traditional packaging equipment cannot meet the needs of fast and accurate packaging of different types of fertilizers, and manual packaging results in low efficiency and high labor intensity. | We customized an Automatic big open mouth bag Packaging Machine for our customer. This equipment has functions such as fast bag changing, automatic adjustment of bag mouth size and precise measurement, and can meet the packaging needs of different fertilizers. | Customers can quickly switch between different types of fertilizer packaging, greatly improving the flexibility of the production line; the packaging speed has been increased by 40%, while the errors caused by manual operation have been reduced; the high degree of automation has reduced labor intensity and improved the working environment of employees. |

| A grain processing plant in the United States | This grain processing plant mainly produces rice, wheat, corn and other grain products, with large annual output and high demand. Since the packaging method of its products directly affects the market sales of the products, the packaging quality and efficiency have become factors that customers are very concerned about. | The customer's original packaging system was unable to cope with the needs of rapid production, especially when there were many varieties of grains and large production fluctuations. Packaging was often inaccurate or too slow, affecting overall production efficiency and product quality. | In order to solve the customer's troubles, we provide an automatic big open mouth bag packaging machine, which supports the packaging of various grain categories and is equipped with an automatic adjustment system that can automatically adjust the packaging parameters according to the particle size and weight of different products. | The packaging speed is 50% faster than the original system, meeting the needs of large-scale production; the packaging accuracy is improved, ensuring the uniformity of the weight of each bag of grain and enhancing the market competitiveness of the product; the stability and reliability of the equipment greatly reduce the downtime of the production line and increase the overall production efficiency by 35%. |

Automatic big open mouth bag packaging machine manufacturers in China

Xinxiang Dahan automatic big open mouth bag packaging machine is a professional packaging equipment designed to efficiently and accurately package products in large-open pockets. The machine has advanced technology and reliable performance and is suitable for various industries and application scenarios. It adopts an automated control system to realize automated bag feeding, bag opening, filling, sealing and discharge processes. The Xinxiang Dahan automatic big open mouth bag packaging machine can adapt to bags of different sizes and capacities, such as 5kg, 10kg, 20kg, 30kg, etc. It is suitable for a variety of materials, including powdered, granular and granular products. Customized packaging solutions can be provided.