What is vertical granule packing machine?

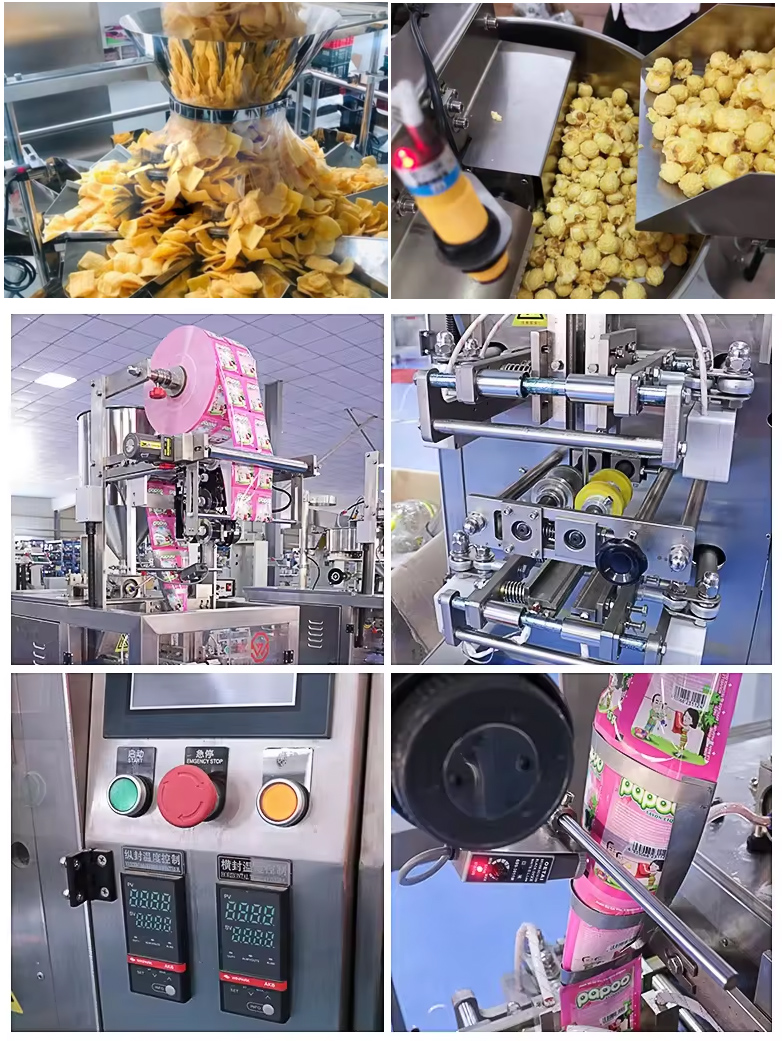

Vertical granule packing machine also known as a vertical form fill and seal (VFFS) machine, is a type of packaging machinery designed specifically for packaging granular products in a vertical format. It is an automated system that performs various tasks, including weighing, filling, sealing, and labeling, to efficiently package granules.

Vertical Granule Packaging Machine This model is designed for efficient and accurate packaging of various granular materials, including grains, seeds, nuts, coffee beans, sugar, food, etc., through an automated system that integrates feeding, weighing, filling, sealing and labeling. Its vertical configuration allows for efficient packaging, providing high-speed operation, precise measurement and reliable sealing to ensure product quality and optimize packaging efficiency.

3 types of vertical granule packing machine for sale

There are several types of vertical granule packing machines available, each designed for specific packaging requirements. Here are three common types:

1.Small Vertical Granule Packing Machine: Used to process small quantities of granules, ideal for packaging applications with limited space or low output. The machine utilizes a vertical form-fill-seal mechanism to weigh, fill and seal pellets into bags or pouches. Despite its smaller size, it still provides precise weighing and filling capabilities, ensuring accurate and consistent packaging. Small vertical granule packaging machines are usually used to package coffee beans, tea, spices, snacks and other granular products.

2. Auger Vertical Granule Packing Machine: Auger-based machines employ a screw-like mechanism to accurately measure and dispense granules by volume. It is commonly used for fine or powdered granular products such as spices, coffee, powdered supplements, and similar items.

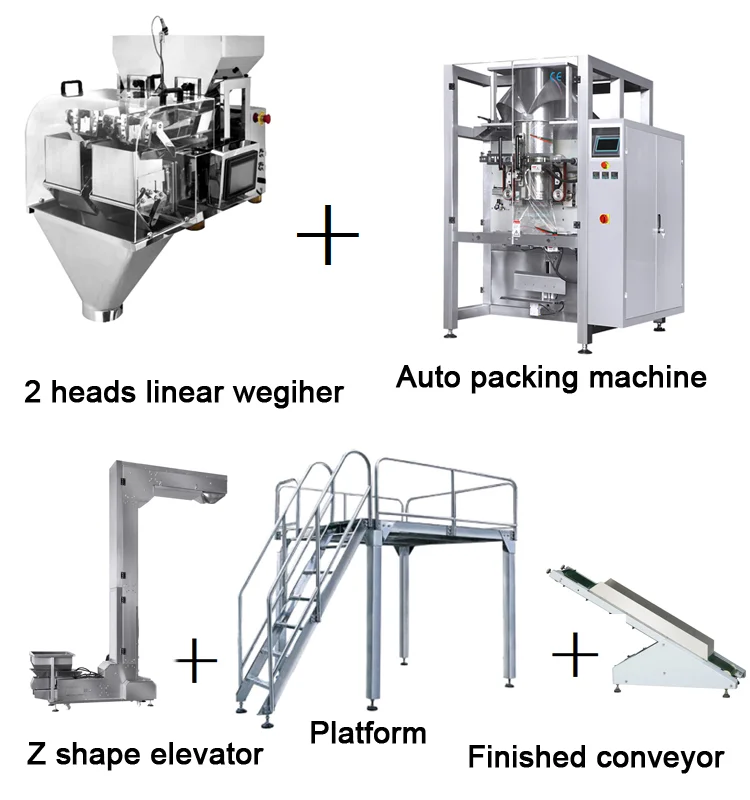

3.Combination Weigher Vertical Granule Packing Machine: This type of machine incorporates a combination or multi-head weigher, which uses multiple weighing heads to achieve precise weight measurements of granules. It is versatile and suitable for a wide range of granular products, including snacks , candies, pet food, and more.

Live Video

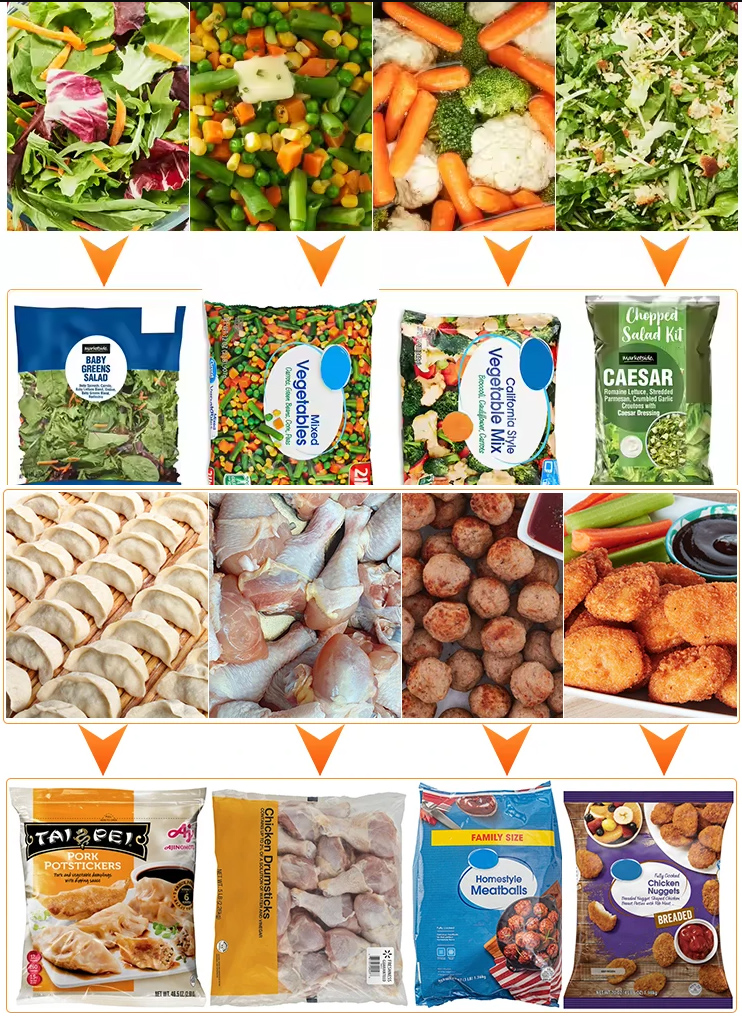

What are the applications of vertical granule packing machine?

1. Food Processing: These machines are commonly used for packaging dry food products such as coffee, tea, spices, grains, and nuts.

2. Pharmaceutical Industry: Vertical granule packing machines are suitable for packaging pharmaceutical powders such as tablets, capsules, and granules.

3. Chemical Industry: They are used for packaging chemical powders and compounds, including fertilizers, pesticides, and detergents.

4. Agricultural Industry: These machines are employed for packaging agricultural products like seeds, fertilizers, and animal feed.

5. Other Applications: Vertical granule packing machines are also used in packaging products such as cosmetics, minerals, and pet food.

How does vertical granule packing machine works?

A vertical granule packing machine works by accurately weighing and dosing granules, filling them into packaging material vertically, and sealing the bags or pouches to ensure product freshness. The machine is controlled by a programmable logic controller or a computerized panel, and it typically includes a conveyor system for continuous operation. It can handle different types of packaging materials and may have optional features like labeling and printing. Overall, the machine streamlines the packaging process, improves efficiency, and maintains product consistency for granular products.

Features of vertical granule packing machine

1. Efficiency and Automation: Vertical granule packing machines offer high efficiency and automation, reducing labor requirements and increasing overall production rates. They can operate continuously, achieving consistent and accurate filling and sealing operations.

2. Flexibility: These machines can be configured to handle a wide range of pre-made pouches or bags, making them suitable for packaging various granule and powder products. They can also be easily adjusted to different pouch sizes and filling weights.

3. Hygienic Packaging: Vertical granule packing machines are designed to maintain a clean and hygienic packaging environment. The enclosed design prevents contamination from external sources, and the use of pre-made pouches eliminates the need for manual handling of the product.

4. Product Preservation: The hermetically sealed pouches or bags protect the granules or powders from moisture, oxygen, and other environmental factors, ensuring product freshness and extending shelf life.

Full vertical granule packing machine specifications

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

Structure of vertical granule packing machine

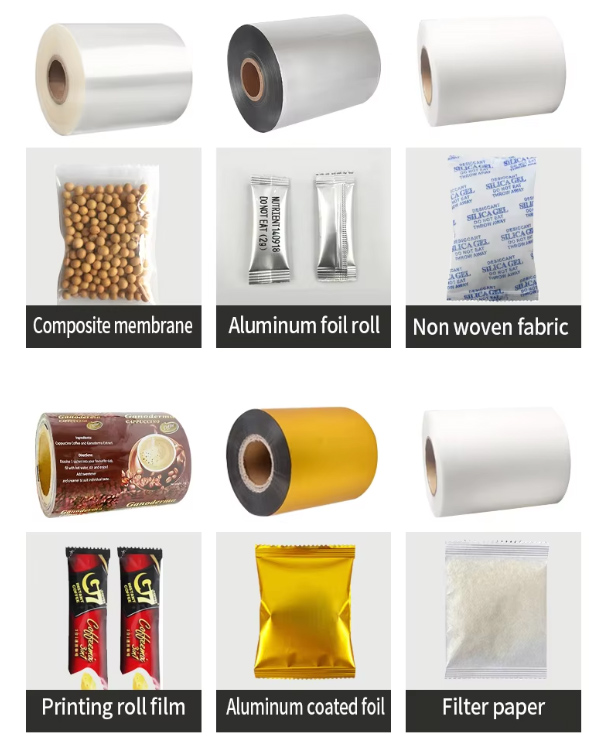

1. Pouch or Bag Feeder: The machine is equipped with a pouch or bag feeder that dispenses pre-made pouches or bags into the machine. These pouches or bags can be made from various materials, such as laminates, plastic, and aluminum foil, to provide the desired barrier properties for the product.

2. Forming Tube: Once the pouch or bag enters the machine, it is guided into a forming tube. The forming tube shapes the pouch or bag into the desired shape and size, typically a vertical or pillow-type bag.

3. Filling System: The formed pouch or bag is then filled with the granules or powders using a filling system that is suitable for the specific product and application. Common filling systems include volumetric dosing, auger filling, and gravity-based filling.

4. Sealing System: After the pouch or bag is filled, it is transported to a sealing station, where it is hermetically sealed to ensure product integrity and prevent contamination. The sealing system typically comprises a heated sealing mechanism that creates a strong and airtight seal.

5. Discharge Conveyor: Once the pouch or bag is sealed, it is discharged from the machine onto a conveyor belt for further processing, such as labeling, date coding, or packaging into cartons.

Packing material

Polyester/aluminizing/Polyethylene, polypropylene/polyethylene aluminum foil/Polyethylene, nylon/Enhanced polyethylene, tea-leaf filtering paper, paper/Polyethylene, etc.

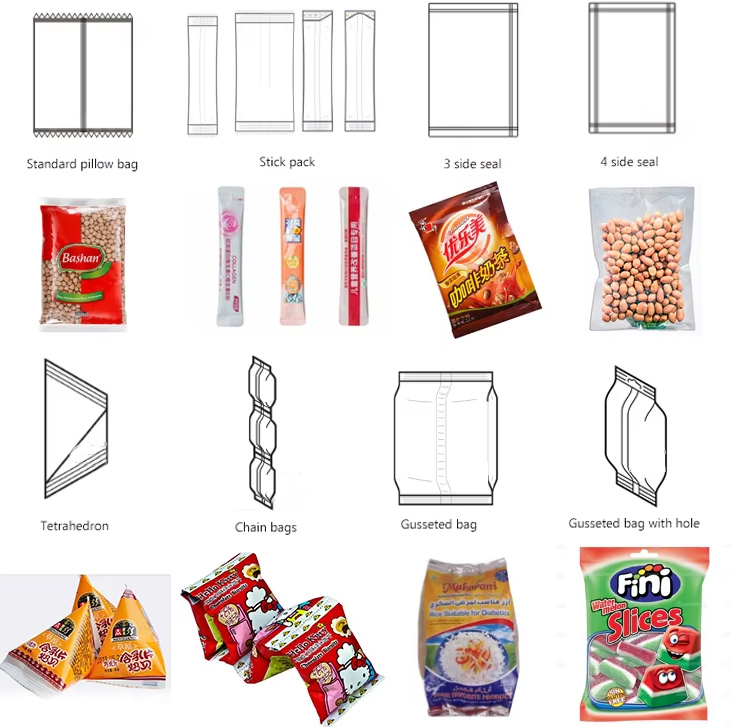

Packaging Type Display

Three-side seal bag: It eliminates the center back seal and provides more space for graphics.

Pillow gusset bag: Gusset bag is a flexible bag with an added piece of cloth called "gusset" to expand the original capacity of the bag. In addition, the gusset can increase the capacity and strengthen the structure of the bag.

Square bottom seal: upright square bottom bag, central or offset back seal, providing a variety of resealable functions.

Continuous bag: A continuous row of multiple bags. The number of serialized bags can be set as needed.

Center seal bar: The center seal bar is also a back center seal package, usually with a larger length and width ratio.

Small bag: used to package a small amount of products or samples, suitable for the packaging of small items such as snacks, medicines, cosmetics, etc.

Pre-made packaging bags: In scenarios where quick packaging is required, the product shape is regular, or the packaging style is not demanding, such as parts, hardware, toys, etc., prefabricated packaging bags are an economical and practical packaging option.

Finished product display

Available options

Packaging speed: Different packaging speeds can be selected according to different production needs, such as high-speed packaging machines and standard speed packaging machines, etc.

Packaging range: The appropriate packaging range can be selected according to the size and weight of the bagged material to ensure that the packaging machine can handle the required granular materials.

Packaging bag type: Different types of packaging bags can be selected, such as back-sealed bags, three-side sealed bags, etc., according to product characteristics and packaging requirements.

Measuring method: Different measuring methods can be selected according to needs, such as measuring cups, weighing machines, etc., to ensure the accuracy and consistency of packaging.

Customer case

| Application scenarios | Packaging materials | Packaging quantity | Packaging size |

| Used in the biomass energy industry, wood pellets are packaged for fuel supply. The equipment has a high degree of automation, reduces labor costs, and adapts to cold regions | Biomass wood pellets | 1-2 tons per hour | The size of the packaging bag is 50kg/bag, suitable for standard ton bags or customized bags |

| Used in agricultural grain processing enterprises to achieve efficient and accurate particle packaging to meet large-scale production needs. The equipment is equipped with high-precision weighing sensors to ensure accurate measurement | Corn, wheat and other grain pellets | 800 bags can be packaged per hour, each bag weighing 5-50kg | 25kg/bag according to customer needs |

| Used in the plastic products industry to solve the problems of low efficiency and serious dust pollution of traditional packaging. The equipment adopts anti-blocking and dust removal technology to improve environmental protection performance and production efficiency | Plastic granules | 1.5 tons can be packaged per hour, suitable for large-scale production lines | The packaging bag size is 25kg/bag, supporting ton bags and small bags |

What is the vertical granule packing machine price?

The price of a vertical granule packing machine can vary depending on several factors, including the machine's capacity, features, brand, and the supplier or manufacturer. Generally, vertical granule packing machines can range in price from a few thousand dollars to tens of thousands of dollars.

To get an accurate and up-to-date price for a vertical granule packing machine, it is recommended to reach out to suppliers or manufacturers directly. They can provide detailed information about the machine specifications and pricing based on your specific requirements.

How to choose an automatic vertical granule packaging machine?

When choosing an automatic vertical granule packaging machine, you need to consider factors such as packaging needs, production scale, packaging accuracy, ease of operation, maintenance and cleaning, optional configuration, after-sales service and cost-effectiveness. After comprehensive consideration, choose the packaging machine that best suits your needs to improve production efficiency, ensure product quality and reduce production costs.

Vertical granule packing machine manufacturers China

Xinxiang Dahan is a manufacturer specializing in the production of vertical granule packing machines. They are committed to providing high-quality, high-efficiency packaging equipment to meet the packaging needs of granular products. Xinxiang Dahan's vertical granule packaging machines use advanced technology and innovative design to achieve high-speed and precise packaging processes, and are widely used in food, pharmaceutical, chemical and agricultural industries. They have won the trust and praise of customers with their high-quality products, reliable after-sales service and rich industry experience. Whether it is small-scale production or large-scale production, Xinxiang Dahan can provide customized solutions to meet the specific needs of customers.