Cocoa Powder for Vertical Automatic Weighing Packaging Machine

Cocoa Powder for Vertical Automatic Weighing Packaging Machine is specially used for the automatic packaging of powdered materials such as cocoa powder. It combines weighing technology and packaging machinery technology, can achieve accurate weighing and automatic packaging of powdered materials, and improve production efficiency and packaging accuracy.

How does the Cocoa Powder Vertical Automatic Weighing Packaging Machine work?

The working principle of the cocoa powder vertical automatic weighing packaging machine usually includes the following steps:

Feeding stage: The cocoa powder is conveyed to the working area of the weighing packaging machine through the feeding system.

Weighing: The cocoa powder enters the weighing device and is accurately weighed under the action of the weighing sensor to ensure that the weight of the cocoa powder in each bag meets the set requirements.

Bag making: The packaging machine cuts a suitable amount of bags from the rolled packaging material and forms them.

Filling: The weighed cocoa powder is conveyed to the bag and filled to the correct position.

Sealing: The cocoa powder in the bag is sealed, usually using heat sealing or cold sealing technology to ensure that the bag mouth is closed.

Cutting: After sealing, the packaging machine cuts and separates the sealed bags to make them independent.

Discharging: The finished bags are sent out of the packaging machine to prepare for the next step of packaging or transportation.

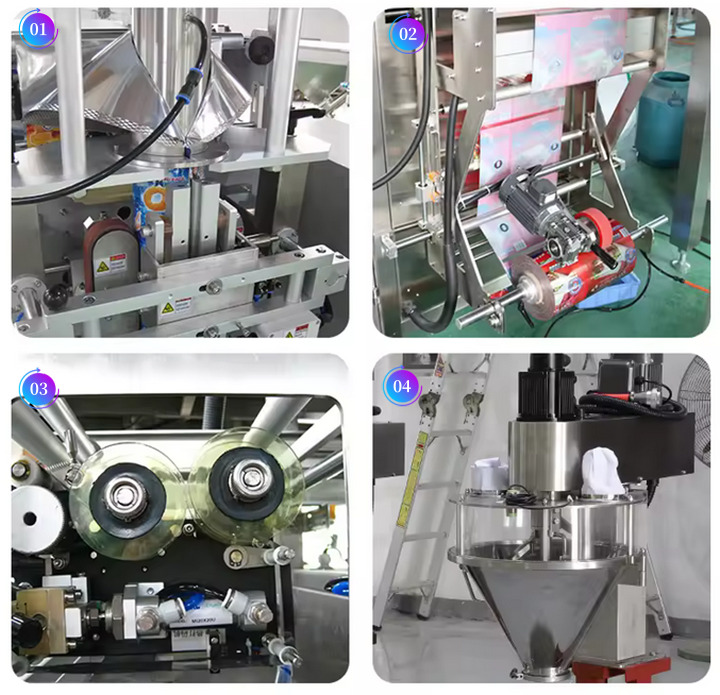

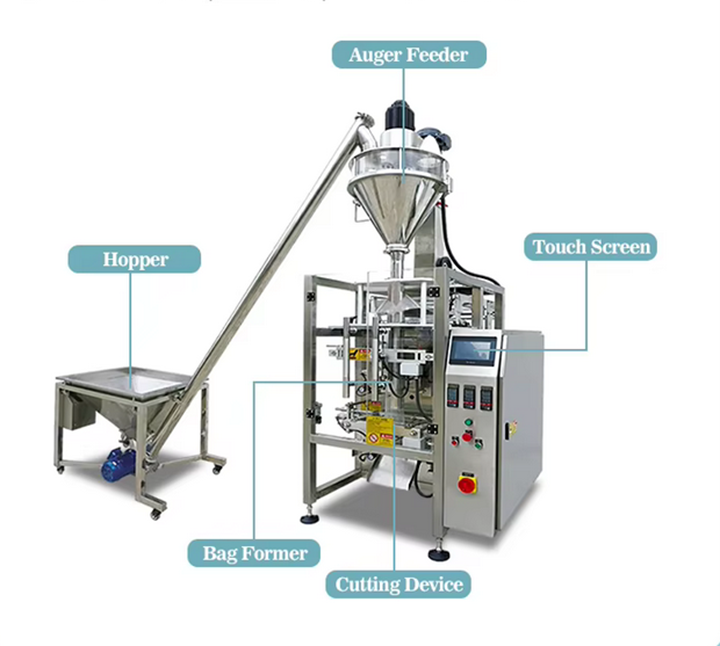

Cocoa Powder Vertical Automatic Weighing Packaging Machine Main Components

These components of the cocoa powder vertical automatic weighing and packaging machine work together to achieve automatic weighing and packaging of cocoa powder, improve production efficiency and packaging accuracy. The following are the main components:

Feeding system: used to transport raw materials such as cocoa powder to the working area of the weighing and packaging machine.

Weighing system: includes weighing sensors, weighing platforms and weighing controllers, which are used to accurately measure and control the weight of cocoa powder in each bag.

Bag making system: used to cut out the right amount of bags from the rolled packaging materials and form them.

Filling system: transports the weighed cocoa powder to the bag for filling.

Sealing system: used to seal the bag to ensure that the bag mouth is sealed. Mainly includes heat sealing or cold sealing technology.

Cutting system: cuts and separates the sealed bags to make them independent.

Control system: The operation and coordination of the entire packaging machine are monitored and adjusted by the control system to ensure the coordinated operation of each part.

What are the advantages of Cocoa Powder Vertical Automatic Weighing Packaging Machine?

Cocoa powder vertical automatic weighing packaging machine has many advantages and features, which makes it widely used in the food processing industry. Here are some common advantages and features:

Accurate weighing: Equipped with a high-precision weighing system, it can accurately weigh the weight of cocoa powder in each packaging bag to ensure product quality and specification consistency.

Efficient automation: It integrates automatic feeding, weighing, packaging, sealing and other functions to realize automated production lines, reduce labor costs and improve production efficiency.

Versatility: The packaging specifications and parameters can be adjusted according to needs, suitable for packaging bags of different specifications and shapes, with high flexibility.

Sanitation and safety: It meets food safety standards and adopts appropriate materials and designs to ensure product hygiene and safety.

Space saving: The vertical design occupies a small area and is suitable for production layout in limited space.

Strong adaptability: In addition to cocoa powder, it can also be used to package other powdered or granular materials, with strong adaptability.

What are the applicable scopes of Cocoa Powder Vertical Automatic Weighing Packaging Machine?

Cocoa powder vertical automatic weighing packaging machine has been widely used in many industries due to its high efficiency, precision and stability. Let's take a closer look at its application scope:

Food industry: It can be used to package milk powder, coffee powder, pepper powder, chili powder, solid beverage granules, such as milk tea powder, fruit powder, etc.

Chemical industry: It is used to package various chemical powders, such as dyes, pigments, fertilizers, etc.

Pharmaceutical industry: It is used to package some pharmaceutical powders that do not contain liquid ingredients.

Pesticide industry: It is used to package some powdered pesticides.

Building materials industry: It is used to package powdered building materials such as cement and gypsum.

Daily chemical industry: It is used to package powdered daily chemical products such as washing powder and detergent.

Service Technical Support

Dahan cocoa powder vertical automatic weighing and packaging machine combines advanced weighing technology, precise packaging system and stable control system to ensure the accurate weight of cocoa powder in each bag. Our equipment is compact in design and easy to operate. It is suitable for packaging bags of various specifications and shapes and has high flexibility and adaptability. We focus on improving product quality and production efficiency to meet customers' needs for packaging accuracy and efficiency. Whether you are a food processing plant, pastry factory or food packaging company, choosing our cocoa powder vertical automatic weighing and packaging machine will inject more efficient and accurate packaging solutions into your production line. Looking forward to working with you to achieve a win-win situation!

Tuesday September-10 2024 15:37:09