Coffee powder for Vertical packaging machine

Coffee powder for Vertical packaging machine is also called the coffee vffs vertical sealing machine. Coffee powder for Vertical packaging machine is suitable for automatic weighing and packaging of coffee powder. It has the functions of measuring, filling, sealing and labeling of coffee powder. It can package coffee powder quickly and accurately according to the predetermined weight or capacity.

Live video

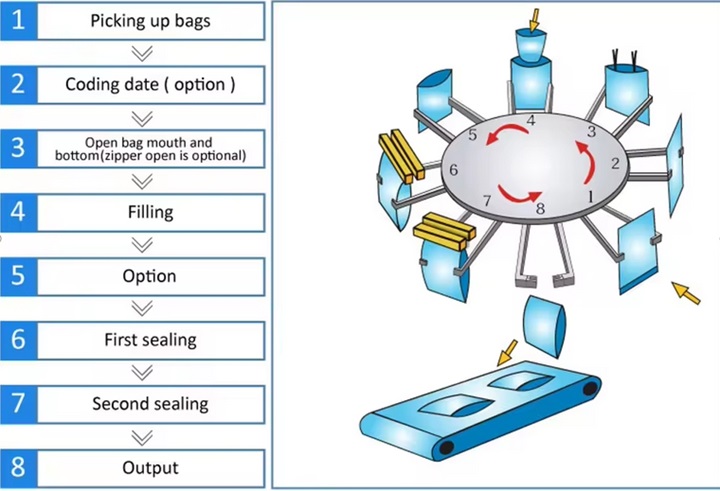

How does the coffee powder for vertical packaging machine work?

The working principle of the coffee powder for vertical packaging machine is to feed the material through the hopper, the metering device accurately measures the weight or volume of the coffee powder, and then fills the coffee powder into the packaging bag, and finally uses the sealing device to seal the packaging bag to complete the automatic packaging process of the coffee powder.

What are the applications of coffee powder for vertical packaging machine?

Coffee capsule/powder filling: used for powder filling in fully automatic capsule coffee machines (such as Nespresso compatible capsules).

Retail coffee powder packaging: bagged/canned coffee powder sold in supermarkets and e-commerce channels.

Catering and hotel industry: hotel mini-bars, restaurant single-brew coffee bags.

Industrial coffee raw material supply: bulk coffee powder used by large food processing plants and baking companies.

In addition, Coffee powder for Vertical packaging machine can also package salt, sugar, pepper, chili powder, spice powder, food additives, cosmetics and medical products, etc.

What are the advantages of coffee powder for vertical packaging machine?

Improve packaging efficiency: The coffee powder for vertical packaging machine adopts automated operation, which can measure, fill and seal coffee powder at high speed and continuously, greatly improving packaging efficiency and saving manpower and time costs.

Precise measurement: The coffee powder for vertical packaging machine is equipped with a precise metering device, which can accurately measure and control the weight or capacity of coffee powder, ensure the consistency of the amount of coffee powder in each packaging bag, and improve the consistency and quality of the product.

Flexible adaptation to different packaging forms: The coffee powder for vertical packaging machine can adapt to different packaging forms, such as pillow bags, triangle bags, stick bags, 3-side sealed bags, 4-side sealed bags, etc., to meet different packaging needs and provide a variety of packaging options.

Maintain packaging quality: The coffee powder for vertical packaging machine has good sealing and freshness preservation, which can effectively prevent the influence of oxygen, moisture and odor on coffee powder, and maintain the freshness and quality of coffee powder.

Enhance brand image: The coffee powder for vertical packaging machine can realize the personalization and customization of packaging, provide an attractive packaging appearance, display the brand image, attract consumers' attention, and enhance the market competitiveness of products.

Coffee powder for vertical packaging machine parameters

| Machine Model | JK-420 | JC520 | JK-620 |

| Film width | Max.420 mm | Max.520 mm | Max.620 mm |

| Bag Length | 80-300 mm | 80~350 mm | 150~350 mm |

| Bag Width | 60~200 mm | 80~250 mm | 100-350 mm |

| Bag Capacity | Max.1500 m | Max.2000 ml | Max. 3000 ml |

| Packing Speed | 5-60 bags/min | 10~50 bags/min | 5~50 bags/min |

| Machine Power | 220V 50160Hz 2KW | 220V,50/60Hz 3KW | 220V 50/60Hz 4KW |

| Machine Size | 1020+1346*1588 mm | 1080*1488*1690 mm | 1250*1700*1780 mm |

| Machine Weight | 650 KG | 700 KG | 750 KG |

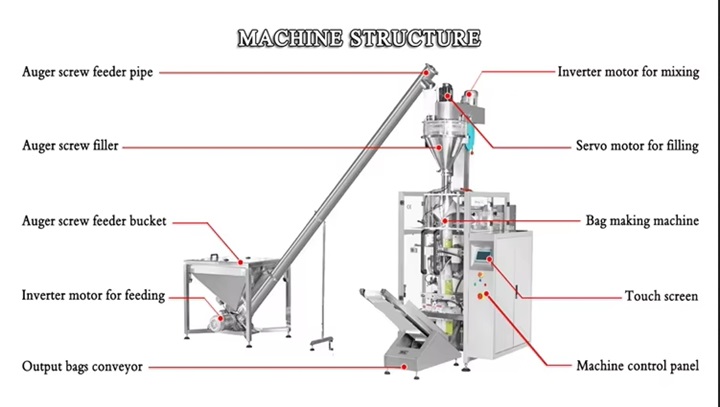

What are the structural components of coffee powder for vertical packaging machine?

Hopper: A container for coffee powder, the capacity and feeding speed can be adjusted as needed.

Measuring device: Used to accurately measure and control the weight or capacity of coffee powder to ensure that the amount of coffee powder in each bag is consistent.

Filling device: Transfers the measured coffee powder from the hopper to the bag, usually using a rotary or vibrating filling mechanism.

Sealing device: Used to seal and seal the bag, usually using heat sealing or pressure sealing to ensure the sealing and freshness of the bag.

Control system: Includes electrical control and automation systems, used to monitor and control the entire packaging process, including feeding, filling, sealing, labeling and other steps.

Conveying system: Used to transfer the packaged coffee powder bags from the filling device to the sealing device, and move the sealed bags out of the machine.

Coffee powder for vertical packaging machine customer case

| Application scenario | Packing volume | Packing speed | Packing size | Packing bag material |

| A Vietnamese instant coffee brand upgraded its production line and needed to solve the problem of packaging machine jamming caused by coffee powder agglomeration. | 10g/bag | 120 bags/minute | 80mm × 50mm three-side seal bag | PET/AL/PE (moisture-proof and light-proof) |

| Italian capsule coffee brand seeks fine powder that meets EU food-grade standards for automatic filling of single-cup capsules. | 5g/grain | 200 grains/minute | Φ35mm × H25mm | Biodegradable PLA |

| American coffee chain needs to automatically package 1 pound of coffee powder to replace the original manual filling. | 454g/bag | 40 bags/minute | 200mm × 300mm four-side sealed stand-up bag | KNY/PE (with one-way exhaust valve) |

Thursday September-04 2025 16:14:51