Liquid for Special-Shaped Packaging Machine

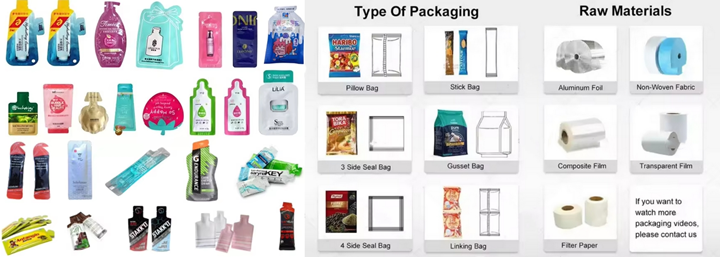

Liquid for Special-Shaped Packaging Machine is suitable for packaging liquid, semi-liquid, and viscous products, such as honey, cosmetics, condiments, oral beverages, liquid medicines, etc.Liquid for Special-Shaped Packaging Machine can also be used to package powders or granules.

Advantages of liquid special-shaped packaging machine

1. This machine is suitable for small bag packaging of liquids, powders, granules, viscous products, etc., and can be customized in any shape, bottle-shaped packaging bags, etc.

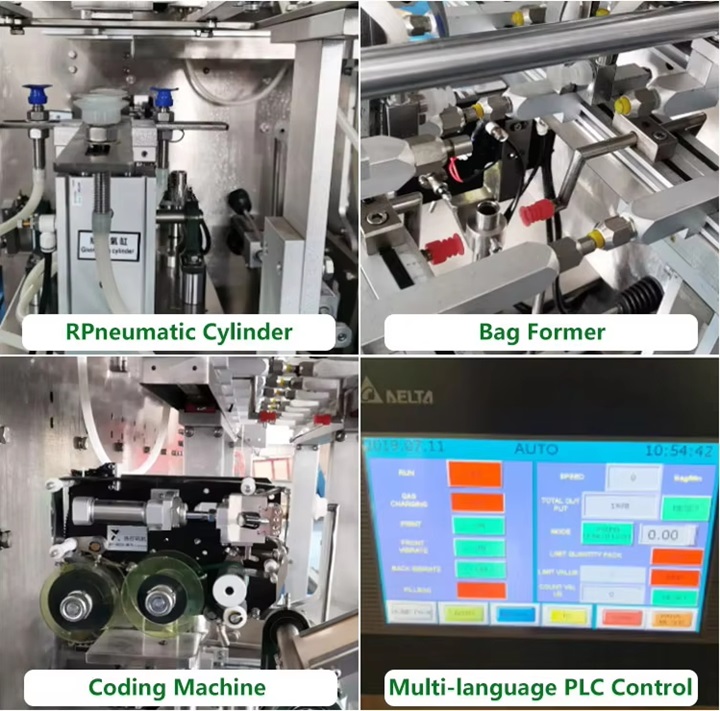

2. All bag making, metering, filling, sealing, cutting, counting and other tasks can be completed automatically, and printers and other options can be added according to customer needs.

3. Upper and lower serrated sealing rings are easy to open, and can be sealed on three sides, back, and four sides according to customer requirements.

4. Touch screen operation, PLC control, stable performance, easy adjustment.

5. Packaging materials: BOPP/polyethylene, aluminum/polyethylene, paper/polyester, polyester/aluminum-plated/polypropylene, nylon/CPP, etc.

Liquid special-shaped packaging machine application

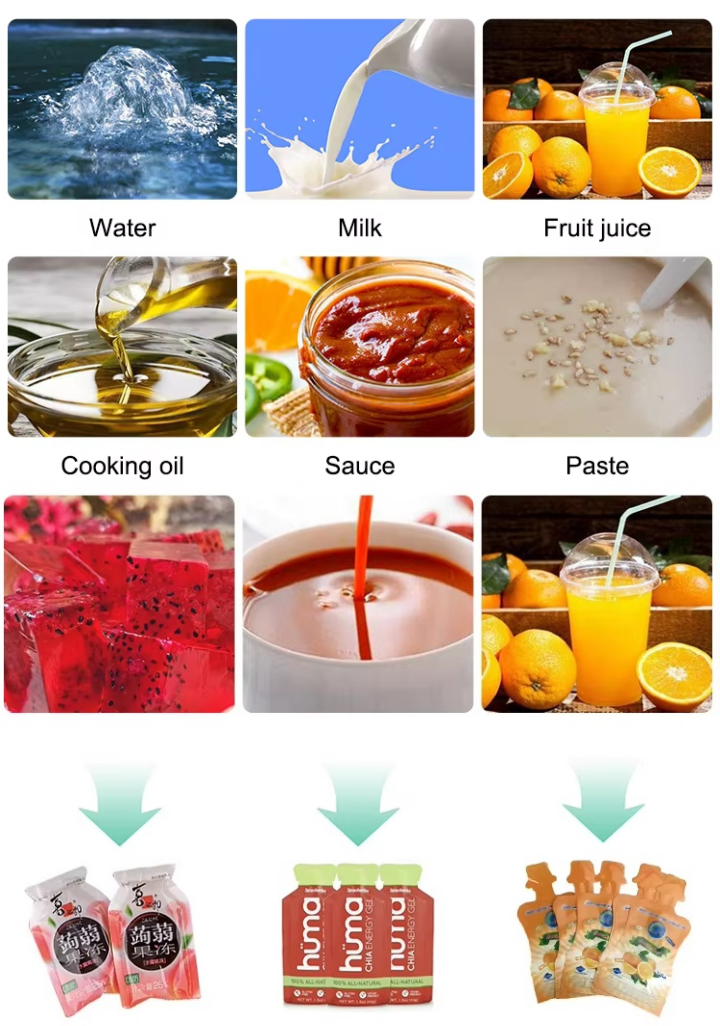

What do you want to pack?

Liquid special-shaped packaging machines are widely used in the food, pharmaceutical and chemical industries to package various liquid products, such as ketchup, seasonings, juice, soy sauce, smoothies, mayonnaise, batter, shampoo, cream, shower gel, etc. Liquid special-shaped packaging machines can effectively complete the metering, filling and sealing of liquid products to ensure the sealing and packaging quality of the products.

Liquid special-shaped packaging machine structure

1. Liquid supply system: used to provide the supply of liquid products and ensure the stable supply of liquid.

2. Metering system: responsible for accurately controlling the flow and metering of liquid, usually including flowmeters, metering valves and sensors and other equipment.

3. Packaging bag conveying system: used to transport the packaging bag from the feeding end to the filling area and sealing area to ensure the smooth transportation and positioning of the bag.

4. Filling system: responsible for filling the specified amount of liquid product into the packaging bag. Common filling methods include gravity filling, pump filling or inflation filling.

5. Sealing system: used to seal the packaging bag. Usually heat sealing technology is used to heat the sealing part to firmly seal the mouth of the packaging bag to ensure sealing and leakproofness.

6. Control system: including PLC controller, touch screen interface and sensor, etc., used to monitor and control the entire packaging process, realize automatic operation and precise packaging control.

7. Discharging system: output the packaged liquid product from the machine, usually through a conveyor belt or a discharging port.

Working principle of liquid special-shaped packaging machine

The liquid special-shaped packaging machine introduces liquid through the liquid supply system, controls the flow rate through the metering system, accurately fills into the packaging bag, seals to ensure sealing, and can perform operations such as coding and labeling. Finally, the packaged liquid product is output, realizing a high-precision, automated and stable packaging process.

Tuesday July-02 2024 14:57:22