What is special shaped bag packaging machine?

Special Shaped Bag Packaging Machine is a type of equipment specifically designed to package products in unique or non-standard bag shapes. It is commonly used in the food, pharmaceutical, and cosmetic industries where products require customized packaging solutions.

The machine is equipped with features and mechanisms that allow it to handle and package products in various shapes such as stand-up pouches, shaped pouches, gusseted bags, spouted pouches, and more. It offers flexibility in terms of bag design, size, and closure options to meet the specific requirements of different products.

Special shaped bag packaging machine for sale

The special-shaped bag packaging machine can be used for a variety of packaging types, and the specific packaging type depends on the characteristics and needs of the product. The following are the types of special-shaped bag packaging machines:

Vertical special-shaped bag packaging machine: Mainly used for packaging liquids, pastes and other materials, with the characteristics of small footprint and easy operation.

Horizontal special-shaped bag packaging machine: Mainly used for packaging powders, granules and other materials, with the characteristics of fast packaging speed and high precision.

Multifunctional special-shaped bag packaging machine: It can flexibly adjust packaging parameters according to different products and packaging requirements to achieve packaging of various products.

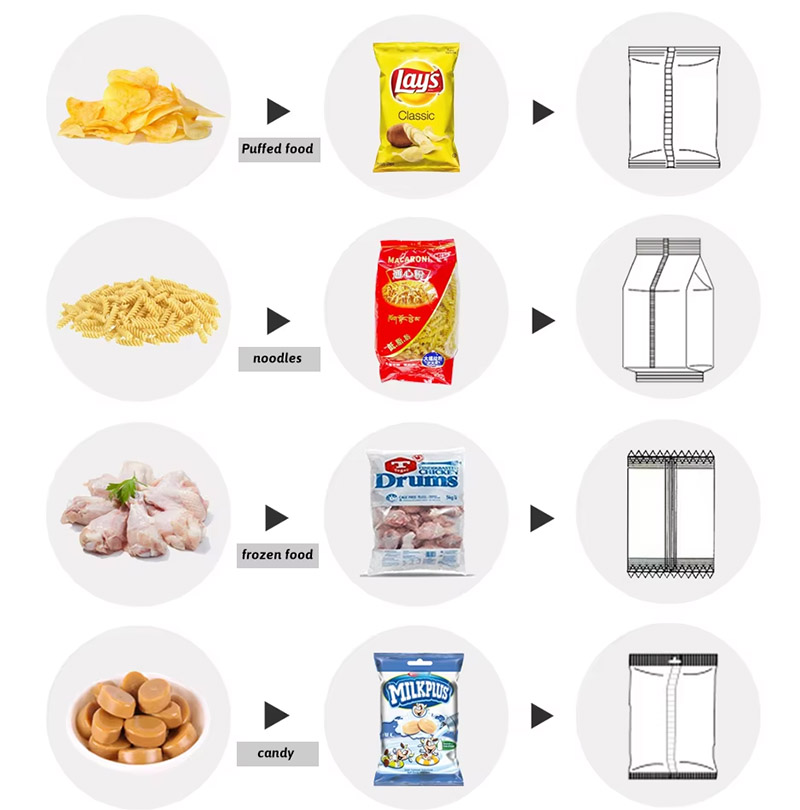

Application of special shaped bag packaging machine

Special Shaped Bag Packaging Machine is widely used in food, daily chemical, pharmaceutical and other industries.

Food industry: used to package candy, biscuits, chocolate, beverages, etc.

Daily chemical industry: used to package shampoo, shower gel, cosmetics, etc.

Pharmaceutical industry: used to package medicines, health products, etc.

How does special shaped bag packaging machine work?

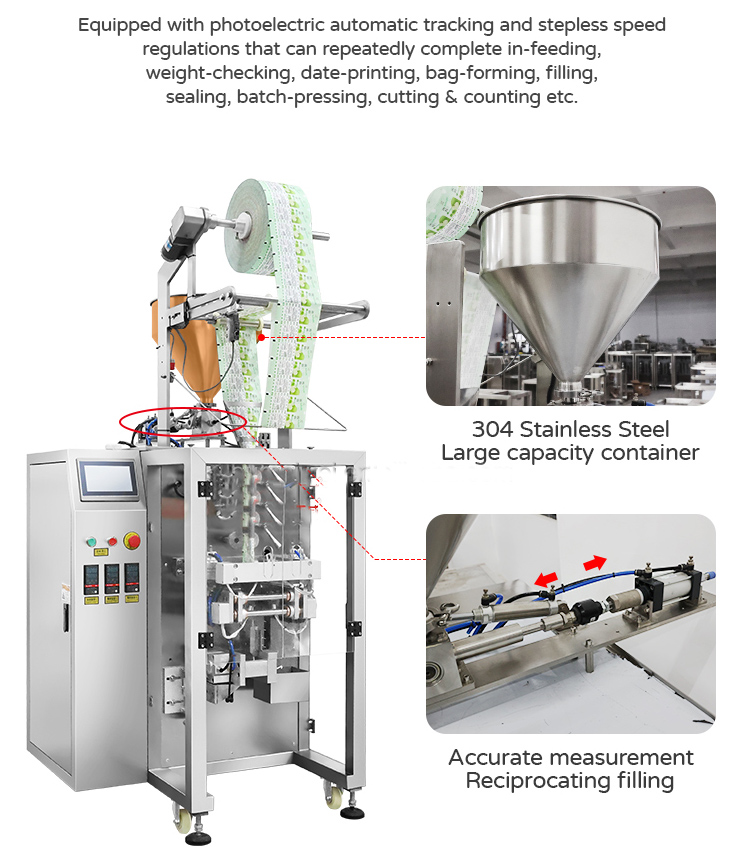

The working principle of the special-shaped bag packaging machine is to form, fill, seal and cut the roll material through a series of steps to complete the packaging of the product. It realizes the automated packaging process by conveying roll materials, forming the shape of the bag, filling the product into the bag, sealing the bag mouth through heat sealing or other sealing methods, and finally cutting the bag into independent packaging units.

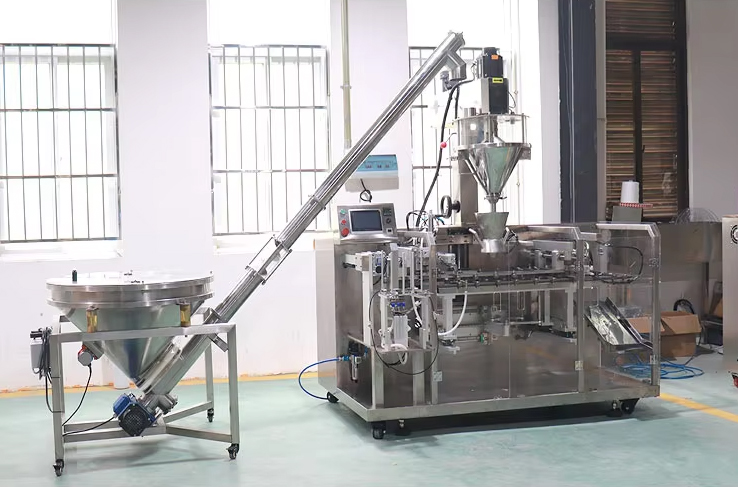

Customer site

Special shaped bag packaging machine specifications

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

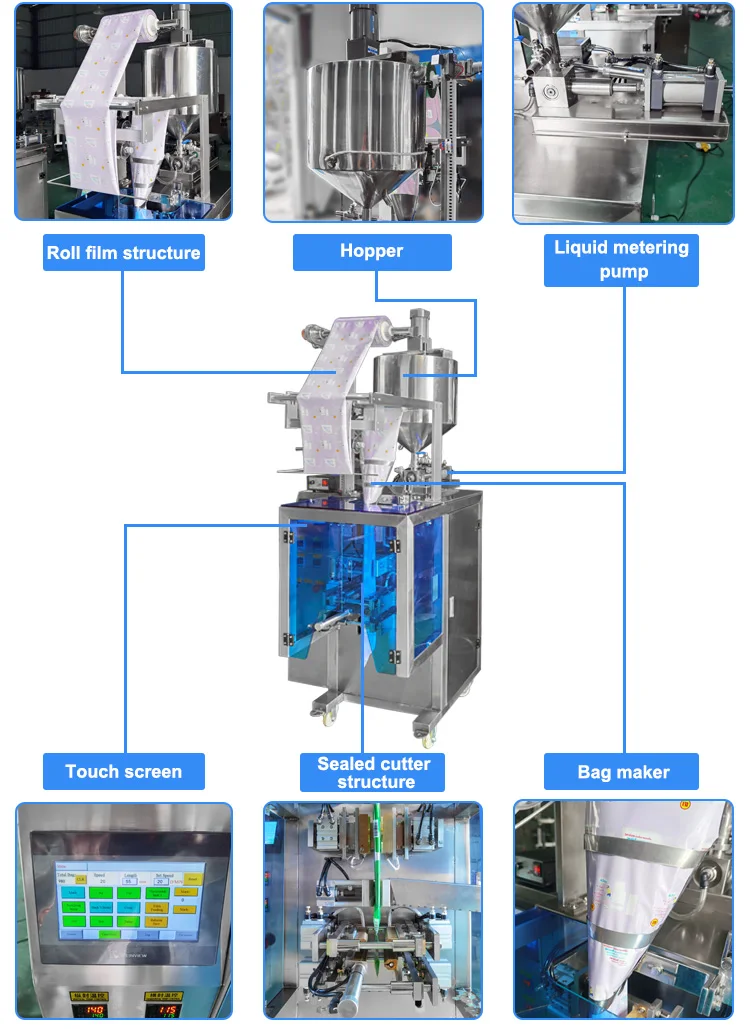

Structure of special shaped bag packaging machine

The special shaped bag packaging machine typically includes the following components:

Bag Forming Mechanism: This mechanism forms the unique shape of the bag using a continuous roll of packaging material. It may involve processes like cutting, sealing, and folding to create the desired bag shape.

Product Filling System: This system fills the product into the formed bags. It can include systems such as auger fillers, volumetric fillers, or weighers, depending on the nature of the product being packaged.

Sealing and Closure: Once the bags are filled, the machine performs sealing operations to provide a secure closure. This can involve heat sealing, zip-lock closures, or other sealing methods suitable for the specific bag design.

Controls and Automation: The machine is equipped with control panels and automation features to monitor and control the packaging process. It may include functions such as adjusting bag sizes, setting fill volumes, and controlling sealing parameters.

Features of special shaped bag packaging machine

Special-shaped bag packaging machines are specially designed for packaging non-traditional shaped bagged products, such as irregular shaped, specially designed bags. Here are some of the features and advantages of special-shaped bag packaging machines:

Specially shaped packaging bags can be customized according to the special needs and market positioning of the product. Unique packaging bags can be customized according to product shape, size, material and other requirements to meet the personalized needs of different brands and products.

Special Shaped Bag Packaging Machine User Feedback

The Special Shaped Bag Packaging Machine ordered by Guangzhou ** is used for the packaging of liquid beverages such as wolfberry puree, juice, lactic acid beverages, collagen liquid, etc. By punching different shapes (such as rounded corners or bottle-like design), the visual appeal of the product is significantly improved, which is suitable for high-end functional beverages and bird's nest direct drinking packaging.

Fully automated vertical design, no need to pre-make bags, roll film directly completes bag making, filling, and sealing, with a production efficiency of 2000-3500 bags/hour.

The Special Shaped Bag Packaging Machine ordered by Shanghai ** Smart is used for precise metering and sealed packaging of medicines and health products, meeting the high requirements of the pharmaceutical industry for hygiene standards. For example, a pharmaceutical company adjusts packaging specifications through modular design to adapt to the needs of special-shaped bags for different drug forms (such as tablets and capsules).

The XH-8 Special Shaped Bag Packaging Machine of Shantou ** Packaging is used for agricultural packaging. Through automated filling and sealing technology, it is adapted to the capacity range of 50-500ml, improves packaging efficiency and ensures sealing.

How to choose reliable special shaped bag packaging machineg equipment?

When choosing a Special Shaped Bag Packaging Machine, consider the following factors to ensure you select the most suitable one for your needs:

1.Packaging Requirements: Assess the specific requirements of your products, such as the size, shape, and material of the bags you need to package. Ensure that the machine you choose can handle the desired bag specifications and meet your production volume.

2.Machine Flexibility: Consider the machine's flexibility in terms of accommodating different bag shapes and sizes. Some machines may be designed to handle a wide range of shapes and sizes, while others may be more limited. Choose a machine that offers the flexibility you require for your current and future packaging needs.

3.Customization Options: If you have unique or specialized packaging requirements, check if the machine can be customized or adapted to meet your specific needs. Some manufacturers offer customization options to tailor the machine to suit your specific products.

4.Quality and Reliability: Look for a reputable manufacturer with a track record of producing high-quality and reliable packaging machines. Read customer reviews and testimonials to gauge the machine's performance and durability.

Do you know about price?

Dahan Packaging Machinery is a leading manufacturer specializing in the production of special-shaped bag packaging machines, committed to providing customers with high-quality, high-efficiency packaging solutions. Our special-shaped bag packaging machines are manufactured using advanced technology and high-quality materials, with the characteristics of automated operation, high-precision packaging, versatility and flexibility. The price ranges from $790.00 to $12,600.00. If you are interested in our special-shaped bag packaging machines or have any packaging needs, please feel free to contact us. We will wholeheartedly provide you with the best quality products and services.

Why choose us as your top special shaped bag packaging machine supplier?

Xinxiang Dahan is a manufacturer specializing in the production of special shaped bag packaging machines, dedicated to providing high-quality special shaped bag packaging machines. They use high-quality materials and advanced manufacturing processes to ensure product stability and reliability to meet customers' high requirements for packaging machinery. With rich experience, technological innovation, high-quality products, perfect after-sales service, and good Recognized by the market, we provide customers with reliable and efficient packaging machinery solutions.