Small Bag Instant Coffee Vertical Weighing Automatic Packaging Machine

Small Bag Instant Coffee Vertical Weighing Automatic Packaging Machine is specially designed for coffee powder and granular materials. It realizes efficient transformation from raw materials to finished products through the integrated process of vertical bag making, intelligent weighing and precise packaging. The equipment adopts a spiral unloading and dust-proof design, and cooperates with the metering system driven by a servo motor to accurately control the weight of each bag (1-25g), meeting the production capacity demand of one million bags per day for a single production line. Its core advantage lies in the vertical weighing structure - compared with horizontal packaging machines, it occupies 40% less space, and uses gravity to drop materials vertically, avoiding the stratification of coffee powder caused by horizontal transportation, ensuring uniform density of each bag.

What are the advantages of small bag coffee vertical weighing automatic packaging machine?

Small bag coffee vertical weighing automatic packaging machine has many advantages and features, making it an important equipment in the coffee production process. Here are some common advantages and features:

High-precision weighing: Adopting straight screw feeding technology to avoid dust adhesion to the seal caused by free fall, the seal qualification rate is increased to 99.8%, and the intelligent weighing system ensures that the error of each bag is ≤±0.5g.

Continuous operation: from film unwinding, bag forming, metering and filling to sealing and cutting output, the packaging speed can reach 40-80 bags/minute, which is 10-15 times that of manual packaging

All stainless steel contact parts: All parts in contact with coffee powder are made of 304 or 316 stainless steel, which meets food grade requirements.

Comparison between vertical weighing automatic packaging machine and traditional packaging method

| Comparison items | Vertical weighing automatic packaging machine | Traditional semi-automatic packaging machine | Manual packaging |

| Packaging speed | 50-120 bags/minute | 15-80 bags/minute | 4-6 bags/minute |

| Measurement accuracy | ±0.1-0.5g | ±1-2g | ±2-5g |

| Manpower requirements | 1 person monitors multiple units | 1 person operates 1 unit | 1 person operates |

| Packaging qualification rate | ≥99.5% | 97-98% | 90-95% |

| Extended shelf life | Can be filled with nitrogen, extending 6-12 months | Ordinary packaging | Ordinary packaging |

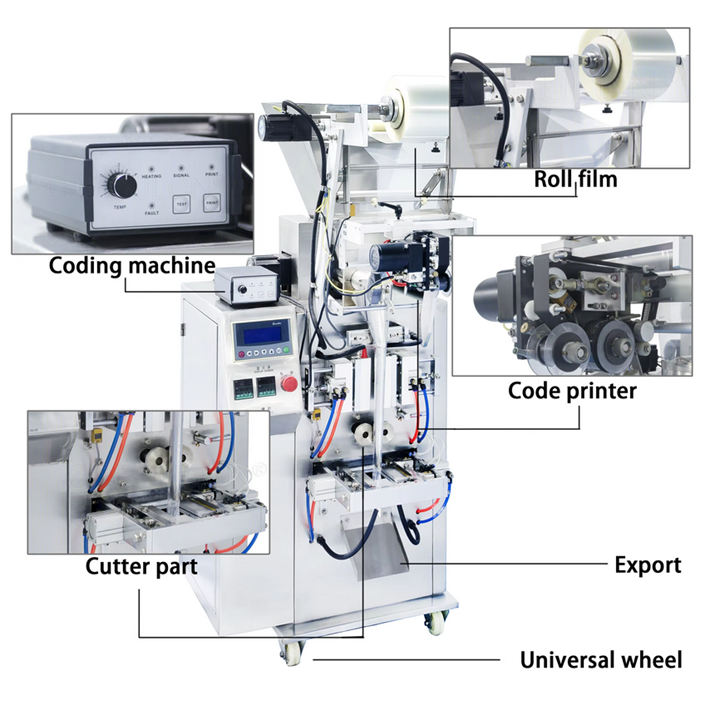

What are the structural components of Small Bag Instant Coffee Vertical Weighing Automatic Packaging Machine?

Small bag coffee vertical weighing automatic packaging machine usually consists of multiple components and systems to achieve automatic weighing, packaging and sealing functions. The following is the general composition structure of this packaging machine:

Feeding system:Includes the storage hopper and conveying system of coffee powder to the weighing and packaging part.

Weighing system:Usually includes weighing sensor, control system and weighing platform, which are used to accurately measure and control the weight of coffee powder in each small bag.

Packing system:This part usually includes the bag feeding system, sealing device and bag conveying system of coffee powder, which are used to pack coffee powder into pre-prepared small bags.

Control system:Controls the operation of the entire packaging machine, including setting packaging parameters, monitoring production process and other functions.

Sealing system:Used to seal the coffee powder in the small bag, usually including heat sealing device or other sealing technology.

PLC control system:Provides an interface for the operator to interact with the packaging machine, which is used to set parameters, monitor the production process and display status information.

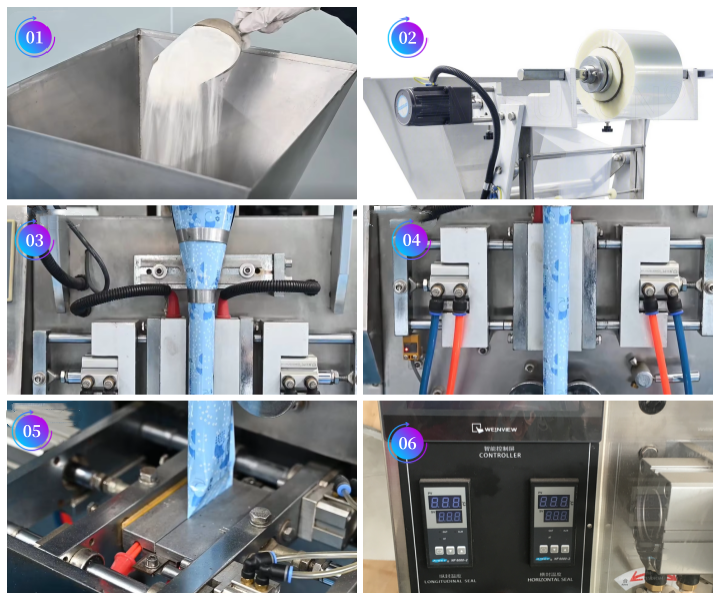

How does the small bag coffee vertical weighing automatic packaging machine package?

The small bag coffee vertical weighing automatic packaging machine usually works in the following steps:

Raw material supply: Coffee powder is fed into the packaging machine through the feeding system, usually through the storage hopper and conveying system to feed the raw materials into the weighing system.

Weighing: The coffee powder will enter the weighing system, where the weighing sensor will accurately measure the weight of the coffee powder in each small bag to ensure that the weight of each bag of coffee powder meets the set requirements.

Packaging: After weighing, the coffee powder will automatically enter the packaging system and be loaded into the pre-prepared small bags.

Sealing: The sealing system will seal the coffee powder in each small bag to ensure the freshness of the coffee powder and prevent leakage.

Cutting and output: The sealed bag is cut and transported to the collection device.

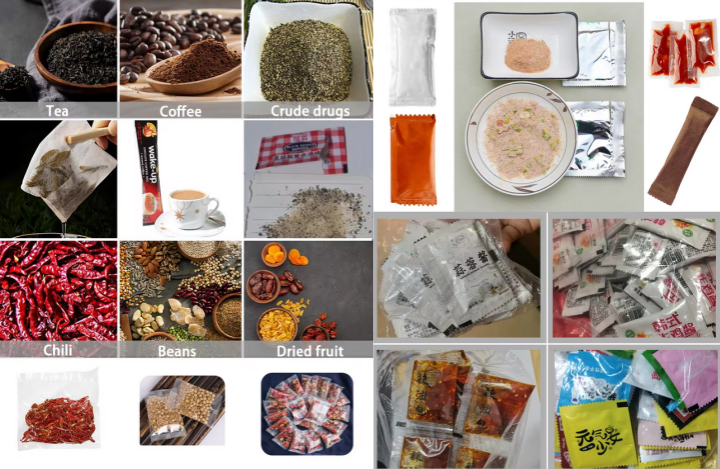

What are the application ranges of Small bag coffee vertical weighing automatic packaging machine?

Although the small bag coffee vertical weighing automatic packaging machine is mainly used to package coffee products, it can also be applied to many other powdered or granular food and non-food products. Here are some examples of other products that can be packaged by the small bag coffee vertical weighing automatic packaging machine:

Instant coffee manufacturers: Package instant coffee, three-in-one coffee powder, black coffee powder, etc.

Food processing plants: Package other powdered or small granular foods, such as milk powder, condiments, instant powders, oatmeal, etc.

Pharmaceutical industry: Package Chinese medicine granules, Western medicine powders, etc. (must comply with GMP standards).

Daily chemical industry: Package laundry detergent, small bags of shampoo, etc.

Small Bag Instant Coffee Vertical Weighing Automatic Packaging Machine price

Dahan Machinery is a professional manufacturer of small bag coffee vertical weighing automatic packaging machines. We are committed to providing efficient packaging solutions for the coffee industry. The price of our vertical weighing automatic packaging machines varies according to the model, function and capacity, generally ranging from tens of thousands to hundreds of thousands, and can be customized according to customer needs. We are committed to providing high-quality products and professional services. Welcome to contact us for more information about products and pricing. We look forward to working with you to jointly improve your production efficiency and product packaging quality.

Small Bag Instant Coffee Vertical Weighing Automatic Packaging Machine plays an important role in the production of instant coffee packaging. You can choose according to the packaging speed, packaging volume and other requirements.

Wednesday September-03 2025 17:52:11