Vegetable Packaging Machine

Vegetable Packaging Machine can automatically complete a series of operations such as weighing, packaging, and sealing of vegetables, and can pack 30 to 150 bags in one minute. It can mainly pack various vegetables such as carrots, tomatoes, green vegetables, eggplants, etc.

Live video

What are the application scopes of vegetable packaging machines?

The vegetable packaging machine can be used to pack various types of vegetables, including but not limited to:

Leafy vegetables: such as spinach, lettuce, lettuce, celery, etc.

Root vegetables: such as carrots, potatoes, onions, celery roots, etc.

Fruits: like tomatoes, cucumbers, eggplants, peppers, etc.

Beans: such as green beans, peas, edamame, etc.

Onions, garlic and ginger: such as green onions, shallots, garlic sprouts, ginger, etc.

Mushrooms: such as shiitake mushrooms, oyster mushrooms, straw mushrooms, etc.

Tofu: such as tofu, dried bean curd, etc.

Root vegetables: such as carrots, potatoes, cabbage, etc.

What are the advantages of vegetable packaging machine?

The vegetable packaging machine has the following advantages in combination with its own composition structure

Compared with manual packaging, the vegetable packaging machine improves the packaging speed and efficiency and saves labor costs.

It can accurately weigh and pack to ensure that the weight of each bag of vegetables is consistent.

It can use different packaging materials to effectively isolate the air, inhibit the growth of bacteria, and extend the shelf life of vegetables.

You can choose the appropriate model according to the characteristics and packaging requirements of different vegetables.

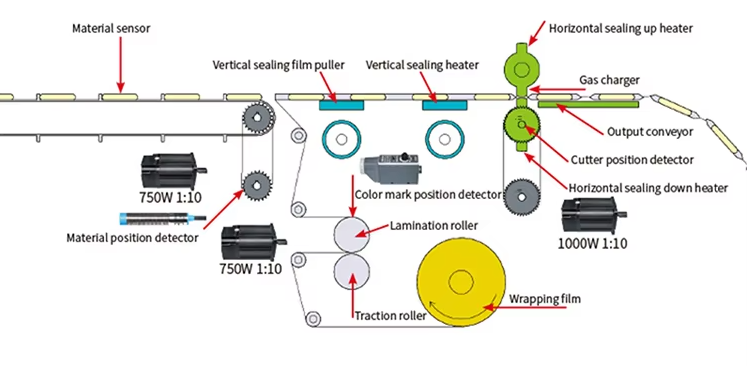

How does vegetable packaging machine work?

The working principle of vegetable packaging machine usually includes processes such as vegetable conveying, weighing, automatic packaging, and sealing. Through automated operation, vegetables can be accurately packaged in bags, boxes or other packaging forms to ensure the hygiene and quality of the products.

Vegetable packaging machine specifications

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

What is the best packaging for vegetables?

Material selection: Choose the appropriate packaging material according to the type and characteristics of the vegetables. For example, PE film has good air permeability and freshness preservation, which is suitable for most leafy vegetables; while vacuum packaging film is more suitable for root vegetables.

Packaging method: Different vegetables are suitable for different packaging methods. For example, leafy vegetables are suitable for pillow packaging, while root vegetables are suitable for vacuum packaging.

Fresh-keeping technology: In addition to packaging materials and methods, fresh-keeping technologies such as modified atmosphere packaging and cold chain transportation can also be combined to further extend the shelf life of vegetables.

Vegetable Packaging Machine Customer Case

| Application Scenario | Packaging speed | Packaging volume | Packaging size |

| A large-scale vegetable planting base in Africa, specializing in pre-packaging leafy vegetables (such as spinach, Chinese cabbage, and lettuce) for supermarkets in Hong Kong and Macau | 40-100 bags/minute (automatically adjusted depending on the length of the vegetables) | Average daily processing of 8-10 tons of fresh leafy vegetables | Bag length: 200-800mm, bag width: 180-280mm, product height: ≤150mm |

| A fresh food logistics center in Shanghai provides clean vegetable packaging (such as carrots, cucumbers, and corn) for chain supermarkets | 30-150 bags/minute (adjustable, 80 bags/minute in normal operation) | Processing 1.5-2 tons of vegetables per hour | Bag length: 130-450mm; bag width: 60-280mm |

| Pakistan's high-end supermarket organic vegetable area requires exquisite independent packaging (such as Chinese cabbage and water spinach) | 20-100 bags/minute | 5000-8000 bags per day | Bag length: 120-450mm; Bag width: 50-200mm (back-sealed pillow bag) |

How to choose vegetable packaging machine?

Production capacity: Choose the appropriate packaging speed according to the production output.

Packing specifications: Consider the size and shape of the packaging bag in combination with the shape and size of the vegetables.

Price: You can compare multiple sales manufacturers and choose the most suitable sales manufacturer based on your needs.

Vegetable packaging machines play an increasingly important role in modern agriculture and food processing industries. Through the application of vegetable packaging machines, the vegetable industry can realize packaging automation, improve production efficiency, reduce costs, maintain product quality, and provide consumers with fresher and more hygienic vegetable products.

Thursday September-04 2025 16:43:41