Detergent Powder Powder Packaging Machine

Detergent Powder Powder Packaging Machine is used to automatically fill washing powder or other powder detergents into bags, boxes, bottles or other packaging containers and seal them. The fully automatic detergent powder powder packaging machine will accurately measure according to the preset parameters and fill the appropriate amount of washing powder into the packaging bag.

Live video

Detergent Powder Powder Packaging Machine for sale

We have small detergent powder powder packaging machines, fully automatic detergent powder powder packaging machines and detergent powder powder packaging machines of different weights for sale. Vest sealing, four-side sealing and three-side sealing can be selected according to customer needs.

Small detergent powder powder packaging machine: It is a kind of equipment suitable for small-scale production or laboratory use, used to package washing powder or other powder detergents. It is suitable for placement in a limited space environment and is easy to move and operate.

Fully automatic detergent powder powder packaging machine: It is an efficient and automated equipment for large-scale production of washing powder or other powder detergent packaging. The packaging process is completed automatically, and no human intervention is required for operations such as weighing, filling and sealing.

5-50kg detergent powder powder packaging machine: It is a kind of equipment suitable for medium-scale production, which can be used to package washing powder or other powder detergents ranging from 5kg to 50kg.

What are the applications of detergent powder powder packaging machine?

Detergent powder powder packaging machines are usually designed to package various powder products. In addition to washing powder, they can also be used to package the following types of products:

Washing powder and detergent: Automatically complete metering, bag making, filling, and sealing, suitable for packaging needs of different specifications (such as 200g~50kg).

Detergent powder and softener powder: Made of anti-corrosion stainless steel to prevent alkaline components from corroding the equipment

Fertilizers, plastic granules: large-capacity packaging (25kg~2 tons/bag), suitable for open-top or valve bag packaging machines.

Chemical raw materials (such as ammonium sulfate, premix): high-precision weighing (±0.2%~0.5%), suitable for materials with different fluidity

Milk powder, seasoning powder: meet food-grade hygiene standards (304 stainless steel) to avoid contamination89.

Starch, coffee powder: use spiral or measuring cup to measure to ensure accuracy

Pesticide powder, veterinary drugs: dust-proof design to avoid cross contamination68.

Fermented feed, soybean meal: suitable for loose materials, optional vibration compaction function

Cement, gypsum powder: large-tonnage packaging (ton bags), equipped with dust removal system.

Graphite powder, talcum powder: wear-resistant design, suitable for high dust environment

What are the advantages of detergent powder powder packaging machine?

Simple structure in linear type ,easy in installation and maintain.

Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

High pressure double crank to control the die opening and closing.

Running in a high automation and intelligent ,no pollution

Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

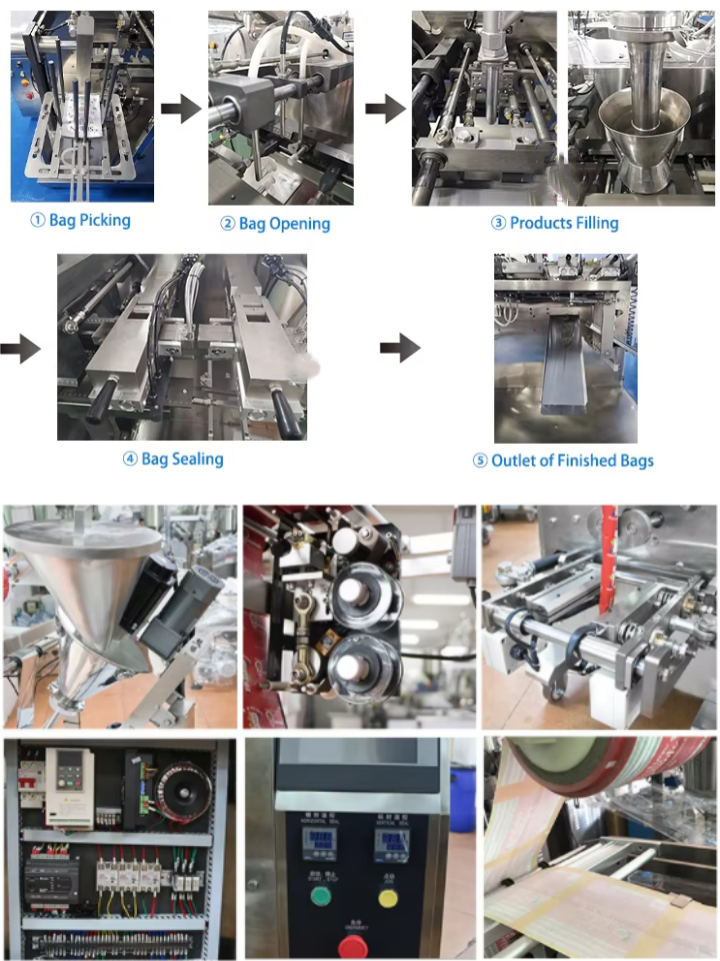

How does a detergent powder powder packaging machine work?

Detergent powder powder packaging machines automate the packaging process through steps such as raw material supply, precise metering, filling, sealing, printing and marking, inspection and packaging export. These machines can efficiently fill washing powder into packaging bags or boxes and ensure the quality and accuracy of the products. They are suitable for large-scale production, improving production efficiency and packaging consistency.

Specifications of detergent powder powder packaging machine

| Model | 720F | 960F | 1200F |

| Track Number | 4-10 Track | 4-12 Track | 4-12 Track |

| Sachet Size(L) | 45-160mm | 45-180mm | 45-180mm |

| Sachet Size(w) | 35-90mm | 35-90mm | 35-120mm |

| Film width | Max:720mm | Max: 960mm | Max:1200mm |

| Film Thickness | 0.06-0.01mm | ||

| Capacity: | 30-45 cycle/min(According to the material condition ) | ||

| Sealing Type | Four side sealing | ||

| Cutting Type: | 1.Straight cutting 2.Zig zag cutting 3. Continuous cutting | ||

| Filling Method | 1. Volumetric cup 2. Weigherr | ||

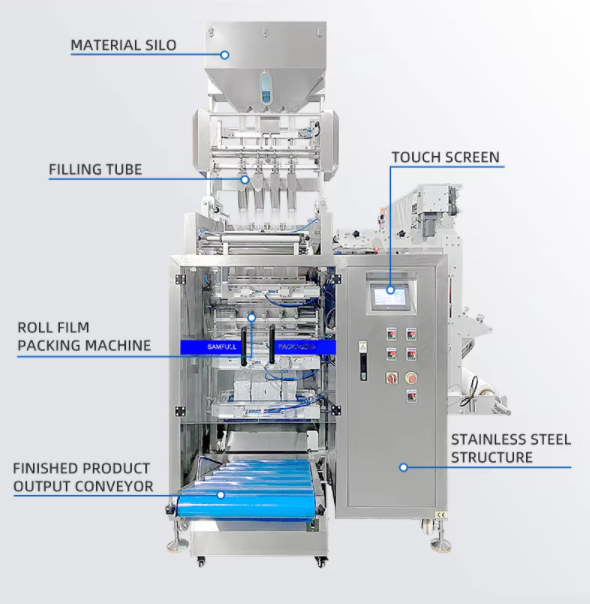

What are the structural components of Detergent Powder Powder Packaging Machine?

Detergent powder powder packaging machines usually consist of the following main components:

Feeding system: used to convey washing powder powder to the hopper or feeding device inside the packaging machine.

Measuring system: used to accurately measure the required amount of washing powder powder to ensure the accurate content of each packaging unit.

Packing bag/box conveying system: conveys the bagged or boxed containers to be packaged to the filling area.

Filling system: used to fill the measured washing powder powder into the bagged or boxed containers to be packaged.

Sealing system: used to seal the bagged or boxed containers to ensure that the washing powder will not leak or get damp.

PLC control system: used to monitor and control the entire packaging process to ensure that each component operates in coordination.

What is the packaging material for detergent powder?

1. Primary Packaging Materials

Plastic Bags (LDPE/LLDPE/HDPE): Most common for consumer-sized packs (1kg–25kg).

LDPE/LLDPE: Flexible, moisture-resistant, and printable for branding.

HDPE: Rigid for larger bags (e.g., 10kg+), offers better stackability;Often include resealable zippers or liner films to prevent moisture ingress.

Cardboard Boxes with Inner Liner: Used for premium or eco-positioned brands.

Inner plastic liner (usually polyethylene) protects powder from humidity.

Paper Bags (Kraft Paper): Eco-friendly option, often with a thin plastic coating or biodegradable liner;Common in bulk industrial packaging (e.g., 25kg+).

2. Bulk Packaging (Industrial Use)

Woven Polypropylene Bags (PP Bags): Heavy-duty, reusable sacks for 25kg–50kg quantities; Often laminated with BOPP for moisture resistance.

FIBCs (Flexible Intermediate Bulk Containers): 500kg–1,000kg capacity, used for shipping to factories;Made from woven polypropylene with UV/waterproof coatings.

3. Sustainability Trends

Biodegradable Films (e.g., PBAT/PLA blends)

Recycled LDPE/PP (Post-consumer recycled content)

Water-Soluble Packets (For single-use detergent doses)

How much is a Detergent Powder Powder Packaging Machine?

| Model type | Packing specifications | Packing speed | Automation level | Price range (US dollars) | Main features |

|---|---|---|---|---|---|

| Vertical fully automatic packaging machine (VFFS) | 50g~5kg | 20~50 packs/minute | Fully automatic | 5,000-20,000 | Bag making, filling and sealing are integrated, suitable for small bags of laundry detergent 7 |

| Bag-feeding fully automatic packaging machine | 1kg~25kg | 15~40 bags/minute | Fully automatic | 15,000-50,000 | Applicable to pre-made bags, high-precision weighing, can be equipped with a variety of bag types |

| Valve bag packaging machine (large bag) | 10kg~50kg | 5~20 bags/minute | Semi-automatic/Fully automatic | 10,000-30,000 | Suitable for industrial large packaging, dust-proof design |

| Multi-function powder packaging machine | 100g~25kg | 10~60 bags/minute | Fully automatic | 12,000-40,000 | Adjustable metering method (screw/measuring cup), suitable for different powders |

| Semi-automatic quantitative packaging machine | 500g~50kg | 5~15 bags/minute | Semi-automatic | 3,000-10,000 | Manual bagging, economical, suitable for small and medium production capacity |

Price influencing factors

Automation level: Fully automatic models are 30%~50% more expensive than semi-automatic models.

Productivity: High-speed models (>50 bags/minute) may double in price.

Material: Stainless steel anti-corrosion models are 20%~40% more expensive than ordinary carbon steel models.

For an accurate quotation, it is recommended to contact the supplier and provide specific parameters (such as packaging specifications, speed requirements, etc.)

How to choose Detergent Powder Powder Packaging Machine?

1. Analysis of the characteristics of detergent powder materials

Flowability: Detergent powder is usually in granular or powder form with medium flowability (may contain additives that cause adhesion).

Solution: Choose a vibrating feeding or spiral feeding system to ensure stable feeding; if the flowability is poor, a stirring device or pneumatic auxiliary feeding needs to be installed.

Corrosiveness: Some detergent powders contain alkaline ingredients that may corrode the equipment.

Solution: The contact parts need to be made of stainless steel (such as 304/316) or anti-corrosion coating.

Dust control: Powder is easy to generate dust, which affects the sealing quality and the health of workers.

Solution: Choose a machine with a sealed filling + dust removal device, or equip it with a negative pressure dust suction system.

2. Packing volume (single bag weight)

| Packing volume | Application | Recommended model |

| Small package (such as 200g~1kg) | Suitable for home retail | Vertical packaging machine (VFFS), high precision (±0.5%~1%), supports small-dose packaging. |

| Large packaging (5kg~25kg) | Commercial or industrial | Open-top quantitative packaging machine (such as valve bag packaging machine), equipped with a large-capacity hopper and coarse/fine two-stage feeding system to ensure speed and accuracy. |

3. Packaging speed (capacity requirements)

| Low speed (<20 bags/minute) | Small-scale production or trial production | Semi-automatic model, manual bagging + automatic weighing. |

| Medium-high speed (30~60 bags/minute) | Mainstream demand | Fully automatic vertical packaging machine (VFFS) or multi-head weigher combined packaging line |

| Ultra-high speed (>80 bags/minute) | Customized solutions are required, such as parallel multi-head weigher + multi-channel packaging machine | |

4. Packaging size and bag type

Bag type:

Back seal/three-side seal: Common in vertical machines, suitable for small bags (such as 200g~2kg).

Four-side seal/self-supporting bag: Customized molds are required, suitable for high-end products.

Valve bags: For large packages (more than 10kg), open-top packaging machines are required.

Size adaptability: Choose models with adjustable bag makers and replaceable molds to meet different length/width/thickness requirements.

5. Bag materials

Common materials: PE/PP composite film, aluminum-plastic composite film, paper-plastic composite bags.

Film (<80μm): A heat-sealing mechanism with precise temperature control is required to avoid loose sealing or burning through.

Thick bags/woven bags: High-pressure heat sealing or bag sewing machines are required, such as large-package valve bags.

Anti-static requirements: Some materials require static elimination devices to ensure that powders are not adsorbed.

6. Other key considerations

Weighing accuracy: Choose a high-precision sensor (±0.1%~0.3%), especially for small packages.

Automation level: Fully automatic models can integrate automatic bagging, filling, sealing, coding, weight checking and other functions to reduce manual intervention.

Hygiene and cleaning: The equipment should be easy to disassemble and clean to avoid residual cross contamination.

Detergent Powder Powder Packaging Machine Manufacturers

As a professional detergent powder powder packaging machine manufacturer, we have become one of the leading manufacturers through continuous technological innovation and quality improvement since our establishment in 2008. The spacious factory in Xinxiang area has advanced equipment and a professional team, including modern production workshops, R&D laboratories and quality inspection centers to ensure the production of high-quality detergent powder powder packaging machines. We focus on customer experience, provide fast and safe delivery services, cooperate with multiple logistics partners, and flexibly choose the transportation method that best suits customer needs. Adhering to the principle of "quality first, customer first", we are committed to creating greater value for customers, providing perfect after-sales service, and providing support and help to customers at any time.

2025-04-03 Thursday 16:44:59