What is Mltihead Packaging Machine?

Multihead packaging machine , also known as a multihead weigher or combination weigher, is a type of packaging equipment used in the food and non-food industries to accurately weigh and package a wide variety of products. It is commonly used for packaging granular, small-piece, or irregularly shaped items such as snacks, candies, nuts, grains, hardware components, and more.

The key feature of a multihead packaging machine is its multiple weighing heads or weighing buckets. These heads are typically arranged in a circular or linear configuration above a central collection chute. Each weighing head contains a dedicated load cell and operates independently.

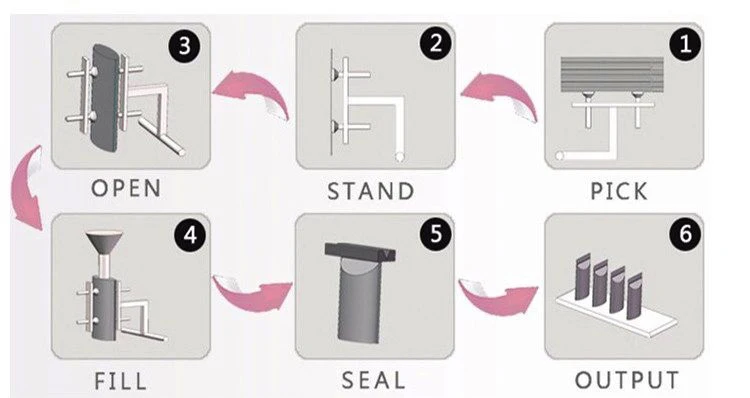

Here's how a multihead packaging machine typically works:

1.Product Distribution: The product to be packaged is fed into the machine's distribution system, usually a vibratory feeder or conveyor belt. This system evenly distributes the product to the multiple weighing heads.

2.Weighing Process: Each weighing head individually measures the weight of the product in its bucket. The load cell in each head detects the weight and sends the signal to the machine's control system.

3.Combination Calculation: The control system receives the weight signals from all the weighing heads and calculates the optimal combination of weights to achieve the desired target weight. This calculation ensures accurate and consistent weight distribution across multiple packages.

4.Product Discharge: Once the correct combination of weights is determined, the machine opens the discharge chutes of the selected weighing heads simultaneously, allowing the product to drop into the packaging material below. This process ensures that each package receives the desired weight.

5.Packaging: The packaging material, such as bags, pouches, or containers, is positioned below the discharge chutes to receive the product. The packaging material is then sealed or closed, completing the packaging process.

Multihead packaging machines offer several advantages, including:

1.High Speed: These machines can achieve high packaging speeds, with some models capable of packaging hundreds of bags per minute.

Accuracy: The individual weighing heads and load cells ensure precise weight measurements, resulting in consistent and accurate package weights.

2.Flexibility: Multihead packaging machines can handle a wide range of product types and sizes, making them versatile for various packaging needs.

3.Efficiency: The simultaneous weighing and discharge process improve production efficiency and reduce packaging time.

4.Integration: They can be easily integrated into existing packaging lines or combined with other packaging equipment, such as form-fill-seal machines or vertical packaging machines.

What products can be packaged by multihead packaging machine?

Multihead packaging machines can be used to package various types of solid products, covering a wide range of applications. Here are some examples of products that the Multihead packaging machine is suitable for:

1. Granular foods: such as potato chips, nuts, candies, puffed foods, candies, oatmeal, dried fruits, etc.

2. Block foods: such as chocolate, biscuits, cakes, jerky, cheese, beef jerky, etc.

3. Granular non-food: such as washing powder, shampoo, dish soap, fertilizer, pigment, cosmetic powder, etc.

4. Non-food block products: such as soap, compressed biscuits, household items, tablets, batteries, hardware parts, etc.

5. Small retail products: such as screws, nuts, plastic accessories, electronic components, small toys, etc.

Overall, multihead packaging machines are popular choices for industries that require high-speed and accurate weighing and packaging of a variety of products.

Friday January-19 2024 13:29:07