What is an automatic film vertical dry chili packing machine?

Automatic film vertical dry chili packing machine is a specialized machine used for packaging dry chillies or similar dry food products. It is designed to automatically complete the packaging process, including feeding, weighing, filling, sealing, and cutting.

The automatic film vertical dry chili packing machine offers a reliable and efficient solution for packaging dry chillies or similar dry food products. It streamlines the packaging process, improves productivity, and ensures the quality and consistency of the packaged products.This automatic machine offers advantages such as high packaging speeds, accurate filling, efficient bag forming and sealing, and the ability to handle a variety of bag sizes and formats. It streamlines the packaging process, improves productivity, and helps maintain the quality and freshness of the dry chili peppers.

Various types of automatic film vertical dry chili packing machine for sale

Here are various automatic film vertical dry chili packing machine for sale, 0-80 automatic pouch chilli powder packing equipment, 0-1kg automatic chilli powder packing equipment, 1-3kg automatic chilli powder packing equipment, 1-5kg semi-automatic chilli powder packing equipment, 5-50kg semi-automatic chilli powder packing equipment, etc. Semi-automatic packaging machines need to put bags on the machine by hand, while automatic ones can automatically complete the whole process of bag forming, weighing, filling, sealing, cutting and counting.

There are several types of automatic film vertical dry chili packing machines available in the market, each designed to cater to different packaging requirements. Here are some common types:

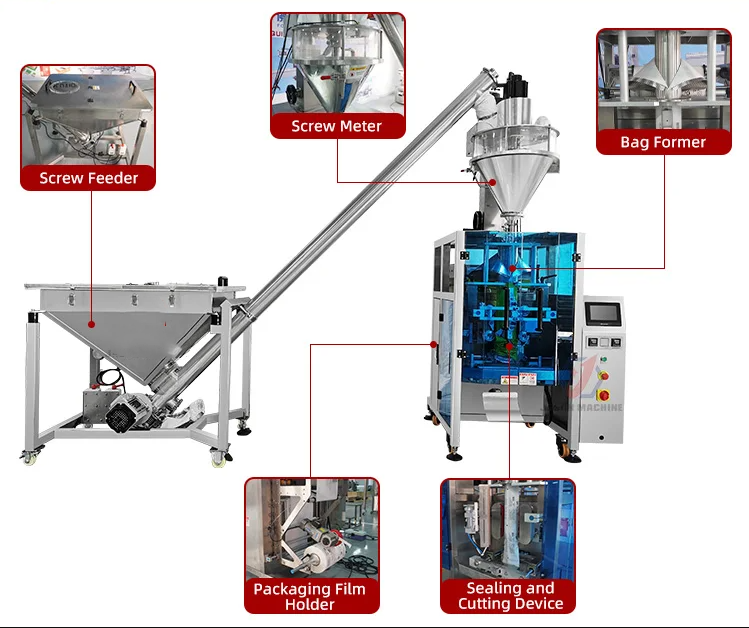

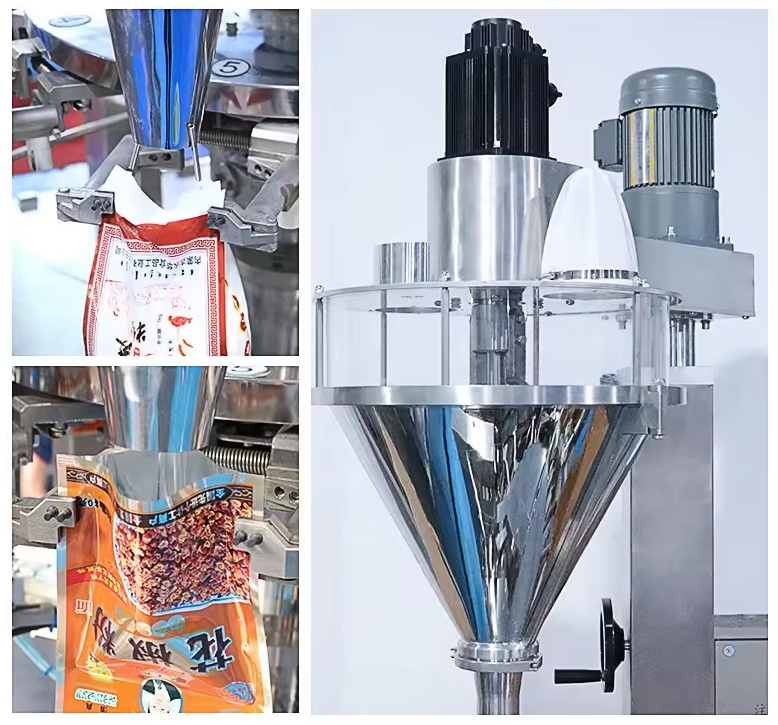

Types1:Auger Filler Automatic Film Vertical Dry Chilli Packing Machine

An auger filling system uses a rotating screw mechanism to accurately measure and dispense a specific weight of dry chili into the packaging pouch. It is suitable for precise dosing and handling of powdered chili.

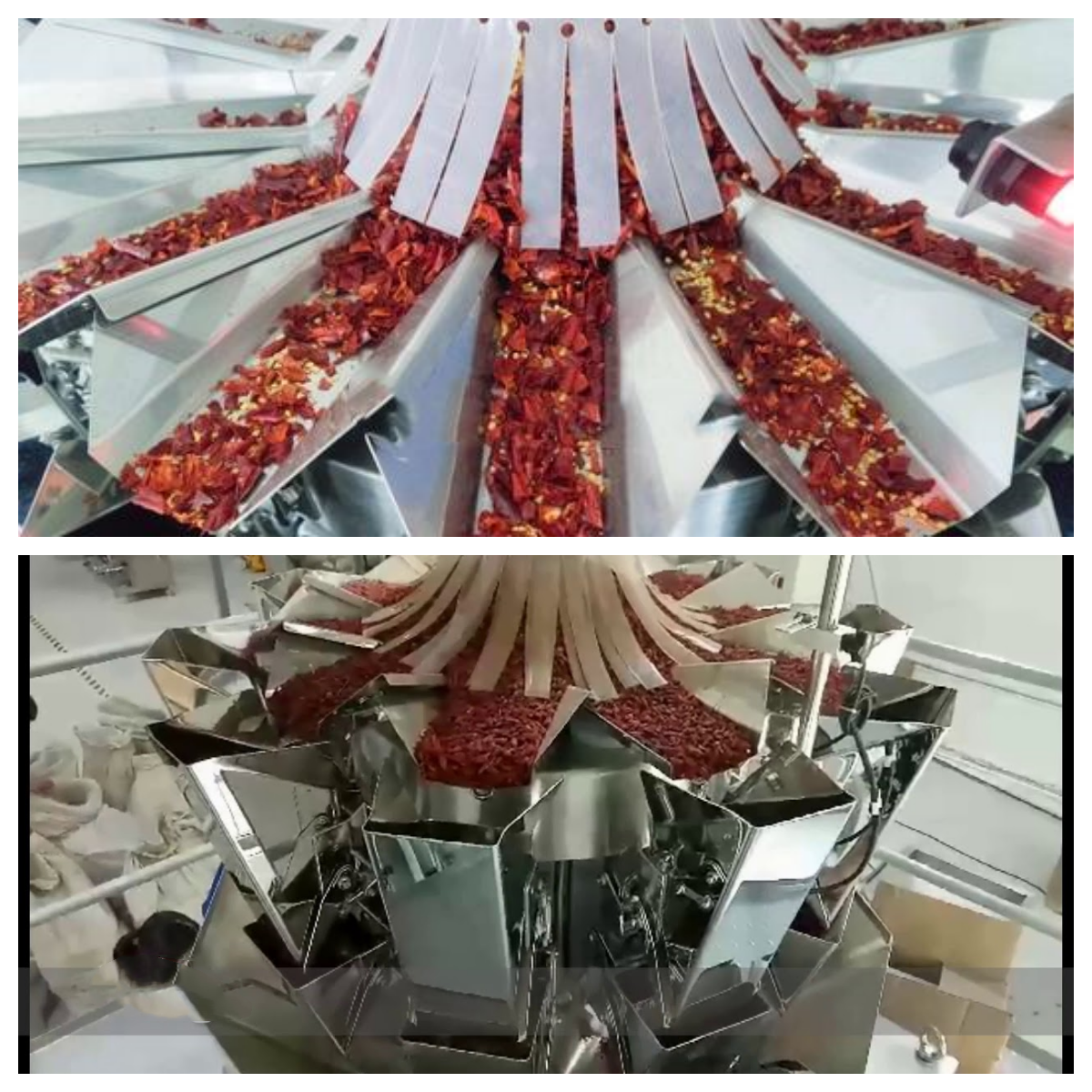

Types2:Combination Weigher Automatic Film Vertical Dry Chilli Packing Machine

A combination weigher, also known as a multi-head weigher, uses multiple weighing heads to individually weigh small portions of dry chili. These portions are then combined to achieve the desired total weight before being dispensed into the packaging pouch. It is suitable for high-speed and accurate weighing of irregularly shaped dry chili.

Types3:Rotary Fill and Seal Vertical Dry Chilli Packing Machine

This type of machine combines a rotary filling system with a sealing mechanism to form, fill, and seal the packaging pouch in a continuous rotary motion. It is suitable for high-speed packaging of dry chili with medium to large production volumes.

Types4:Pre-Made Pouch Vertical Dry Chilli Packing Machine

A pre-made pouch packaging machine is designed to handle pre-formed pouches or bags. It can be equipped with various filling systems, such as volumetric cup fillers, auger fillers, or combination weighers, to package dry chili efficiently.

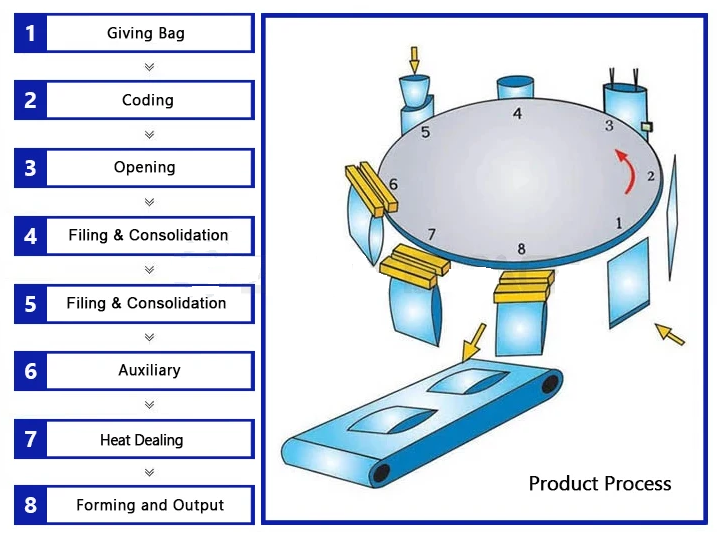

How does automatic film vertical dry chili packing machine works?

Here are the key features and steps involved in the operation of this machine:

Film Unwinding: A roll of packaging film or material is unwound and fed into the machine. The film is typically a flexible material that provides protection and preserves the quality of the dry chili peppers.

Bag Forming: The packaging machine forms a tube or a vertical collar from the film. The film is guided and sealed lengthwise to create a continuous tube.

Product Filling: The dry chili peppers are automatically dispensed into the formed pouches. This can be achieved by a filling system that accurately measures and drops the desired quantity of dry chili peppers into each pouch.

Sealing: Heat sealing bars or rollers apply heat and pressure to seal the top and bottom of the pouches, ensuring a secure and airtight package for the dry chili peppers. Additional sealing mechanisms like tear notches or zipper closures may also be incorporated.

What are the applications of automatic film vertical dry chili packing machine?

The primary application of the machine is for packaging dry chili peppers. It can efficiently weigh, fill, seal, and cut individual packages of dry chilies, ensuring their freshness and preventing contamination.

Automatic film vertical dry chili packing machine is a versatile packaging solution for a wide range of dry food products. Its applications extend beyond chili peppers to include spices, herbs, tea, coffee, nuts, snacks, and other granular products.

Live video

Features of automatic film vertical dry chili packing machine

1. Automatic Operation: The machine is fully automatic, eliminating the need for manual labor. It automates the entire packaging process, from product feeding to bagging and sealing.

2. Vertical Design: The vertical design of the machine allows for compact placement in your production facility, optimizing space utilization.

3. Adjustable Packaging Parameters: The machine allows for adjustable packaging parameters, such as package size, filling volume, and sealing temperature. This flexibility enables the machine to accommodate different packaging requirements and achieve desired packaging results.

4. High Efficiency and Accuracy: The Automatic Film Vertical Dry Chilli Packing Machine operates at a high speed, allowing for efficient packaging and increased productivity. It also ensures accurate weighing and precise packaging to maintain consistency in package weight and appearance.

Differences between Semi-automatic amd automatic film vertical dry chili packing machine

Semi-automatic film vertical dry chili packing machine: 1-5kg and 5-50kg powder packing machine for chilli belong to semi-automatic machine. When using them, you should put the bag on the filling hole by hand to fill the same weight of material. Sealing device and sewing device are available to match.

Automatic film vertical dry chili packing machine: Chilli powder packing machine for 0-80g, 0-1kg, and 1-3kg are automatic packing machine. 0-80g powder packing equipment pushes chilli powder by a screw at an angle, suitable for pouch chilli powder packaging within 80g. 0-1kg powder packaging machine with a horizontal screw applies to pack chilli powder of not more than 1kg. 1-3kg powder packing equipment is equipped with a vertical screw, working efficiently. All these three kinds of chilli powder packaging machines can automatically complete bag forming, weighing, filling, sealing, cutting, and counting. They weigh material according to the spiraling screw.

Automatic film vertical dry chili packing machine specifications

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

Structure of automatic film vertical dry chili packing machine

The structure of an automatic film vertical dry chili packing machine typically consists of a film unwinding mechanism, bag forming unit, product filling system, sealing components, and a cutting/discharge system. These components work together to efficiently package dry chili peppers. The machine is designed to automate the process, ensuring accurate filling, secure sealing, and precise cutting for individual packages of dry chili peppers.

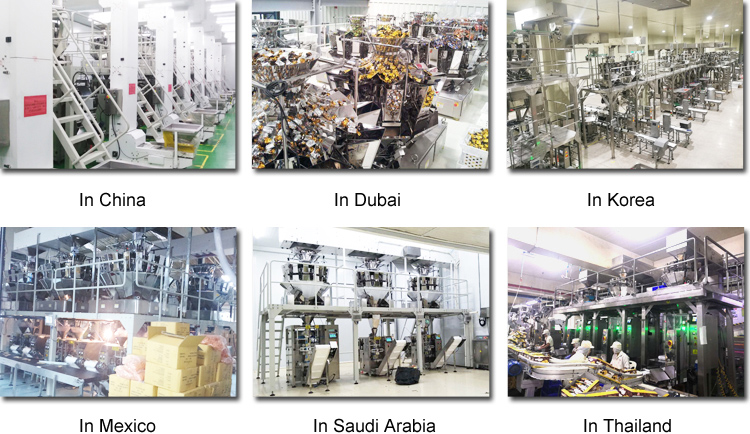

Customer case

| Application Scenario | Packaging Capacity | Packaging Size |

| A food processing plant in the Philippines - Dry chili powder packaging, efficient and hygienic automated packaging to ensure product sealing and shelf life | 40-50 packs/minute (single pack weight: 100g, 200g, 500g) | Width: 80-150 mm; length: 120-200 mm |

| An African agricultural cooperative - Packaging of dried chili segments; fast packaging to meet the needs of different specifications, easy to transport and sell | 30-40 packages/minute (single package weight: 250g, 500g, 1kg) | Width: 100-180 mm; length: 150-250 mm |

| A condiment company in Pakistan - Packaging of dried chili whole fruits; high-precision weighing to ensure consistent weight of each package and enhance brand image. | 20-30 packs/minute (single pack weight: 50g, 100g, 250g) | Width: 60-120mm; Length: 100-180mm |

Automatic film vertical dry chili packing machine price

The price of an automatic film vertical dry chili packing machine can vary depending on several factors, including the machine's capacity, features, brand, and additional customization options. Generally, these machines are considered capital investments for businesses, and their prices can range from several thousand dollars to tens of thousands of dollars.

To get an accurate price for a specific machine, it is recommended to contact manufacturers or suppliers directly. They can provide detailed information about the machine's specifications, pricing, and any additional costs associated with customization, installation, and after-sales support.

How to choose the correct automatic film vertical dry chili packing machine?

When choosing an automatic film vertical dry chili packing machine, consider the following factors:

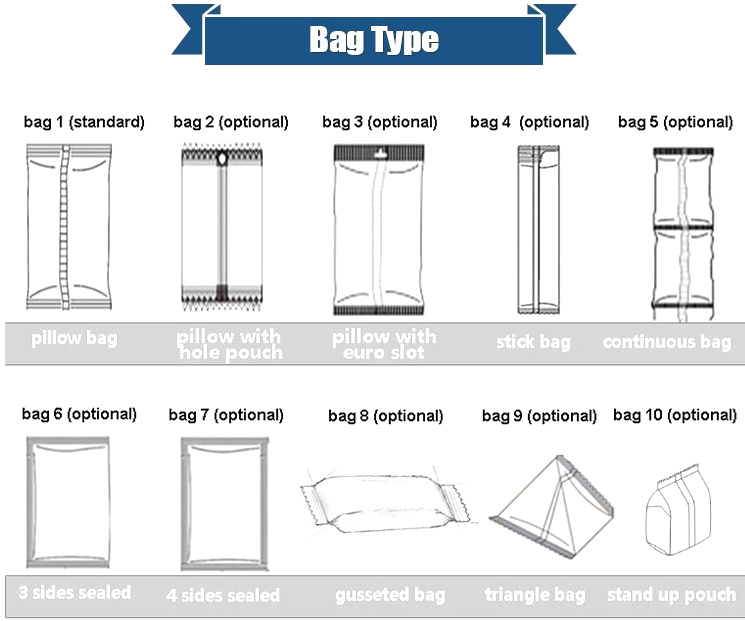

1. Packaging Bag Type

| Packaging type | Back-Sealed Bag (Pillow Bag) | Three-Side Sealed Bag | Four-Side Sealed Bag | Stand-Up Pouch (Doypack) |

| Features | Sealed on the back, open at the top and bottom. | Sealed on three sides, leaving one side open for filling. | Sealed on all four sides, creating a fully enclosed package. | Stands upright, often with a zipper or spout. |

| Applications | Suitable for dry chilli powder or small-sized chilli flakes. | Ideal for dry chilli flakes or whole dried chillies. | Suitable for premium dry chilli products or vacuum-sealed packaging. | Ideal for retail packaging of dry chilli powder or flakes. |

| Advantages | Simple design, cost-effective, and easy to fill. | Provides a clean, professional look and better product protection. | Enhanced product freshness and shelf life. | Attractive design, convenient for consumers, and resealable. |

2. Packaging Weight

| Weight | Small Packages (50g - 250g) | Medium Packages (250g - 1kg) | Large Packages (1kg - 5kg) |

| Machine Requirement | High-precision weighing system (e.g., multi-head weigher). | Medium-capacity filling system. | Heavy-duty filling system with high-speed capabilities. |

| Applications | Retail packaging for household use. | Bulk packaging for small businesses or wholesale. | Industrial or wholesale packaging. |

| Example | 50g or 100g dry chilli powder for supermarkets. | 500g dry chilli flakes for restaurants or food processors. | 1kg or 5kg dry chilli whole for large-scale food production |

3. Packaging Volume (Throughput)

| Packaging Volume | Low Volume (10-30 packages/minute) | Medium Volume (30-60 packages/minute) | High Volume (60-100+ packages/minute) |

| Applications | Small businesses or low-demand products. | Medium-sized businesses or moderate-demand products. | Large-scale production or high-demand products. |

| Example | Artisanal dry chilli products for niche markets. | Dry chilli flakes for regional distribution. | Dry chilli powder for national or international markets. |

4. Packaging Dimensions

| Dimensions | Bag Width | Bag Length | Bag Thickness |

| Range | Typically 60mm to 200mm. | Typically 100mm to 300mm. | Typically 50-150 microns. |

| Selection | Choose based on the product volume and bag type. | Ensure the bag length accommodates the product and allows for proper sealing. | Thicker films are required for heavy or sharp products (e.g., whole dried chillies). |

| Example | 80mm width for 100g dry chilli powder. | 150mm length for 250g dry chilli flakes. |

What can we provide if cooperate with us?

We have an extremely strict quality inspection system for our products. Before shipment, we will take photos and videos for you.

We supply English manuals and video teaching. And we provide 24-hour online service. You can contact us if you have any questions about our products, and we will reply to you as soon as possible.

If the machine has a problem, we will check what happened after receiving your feedback video. If the problem is triggered by improper operation, we can provide the parts at the original price. while if not human improper behaviour, we will provide parts for free.

As a manufacturer and supplier, we can provide the best price for you, and we support custom services according to your actual requirements.

Recommend Product

Automatic Spice Powder Packing Machine

Automatic Vertical Film Bag Potato Frozen French Fries Packaging Machine

Automatic Vertical Film Weighing and Packaging Machine for Chips