What is an automatic vertical baler packing machine?

Automatic vertical baler packing machine, also known as a vertical baler or vertical baling press, is a specialized machine used for compressing and packaging various materials into compact bales. It is commonly used in recycling facilities, warehouses, manufacturing plants, and other industries where large volumes of waste or recyclable materials need to be efficiently managed.

Automatic vertical baler packing machine offers an efficient and convenient solution for compressing and packaging various materials into compact bales. It helps reduce waste volume, optimize storage space, facilitate recycling efforts, and improve overall waste management practices in various industries.

How does automatic vertical baler packing machine works?

The automatic vertical baler packing machine operates by feeding materials into a vertical chamber. Once inside, the machine applies hydraulic or mechanical pressure to compress the materials into compact bales. After reaching the desired compression level, the machine automatically ties or wraps the bales with straps or plastic wrapping. This process ensures efficient packaging, space-saving storage, and improved handling of various materials, making it a valuable tool in waste management and recycling industries.

What are the applications of automatic vertical baler packing machine?

Automatic vertical baler packing machine) can be used to pack a variety of products and is particularly suitable for compressing materials into compact packages. Here are some common examples of products that can be packaged using automatic vertical compression packaging machines:

Paper and cardboard: Paper, cardboard, cartons, cardboard packaging materials, etc.

Plastic: plastic bottles, plastic films, plastic packaging materials, plastic containers, etc.

Textiles: textile waste, cloth, yarn, textile products, etc.

Metal: metal cans, iron sheets, iron wire, iron products, etc.

Flexible packaging materials: plastic bags, paper bags, composite films, foam plastics, etc.

Paper and plastic waste: waste paper, waste plastic, packaging waste, etc.

Lightweight items: foam plastics, sponges, foamed plastics, etc.

Live Video

What is the function of automatic vertical baler packing machine?

The automatic vertical baler is an indispensable piece of equipment in the modern packaging industry, providing enterprises with efficient and reliable packaging solutions. Compared with traditional horizontal balers, it has the following features:

Space Optimization: By compressing materials into compact bales, the machine helps optimize storage space. Baled materials take up significantly less space compared to loose or unprocessed materials, allowing businesses to free up valuable floor space in warehouses, recycling facilities, and storage areas.

Efficient Waste Handling: The machine streamlines waste handling processes by automating the compaction and packaging of materials. It reduces the time and effort required to manually handle and transport loose or bulky waste, improving overall operational efficiency.

Cost Savings: By reducing waste volume and optimizing storage space, businesses can save on waste disposal costs. Baled materials are more cost-effective to transport and dispose of, as they occupy less space and can be efficiently loaded onto trucks or containers.

Environmental Sustainability: The automatic vertical baler packing machine promotes environmental sustainability by facilitating recycling efforts. Compressed and baled materials are easier to transport and process at recycling facilities, increasing the likelihood of successful recycling and reducing the amount of waste sent to landfills.

Automatic vertical baler packing machine specifications

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

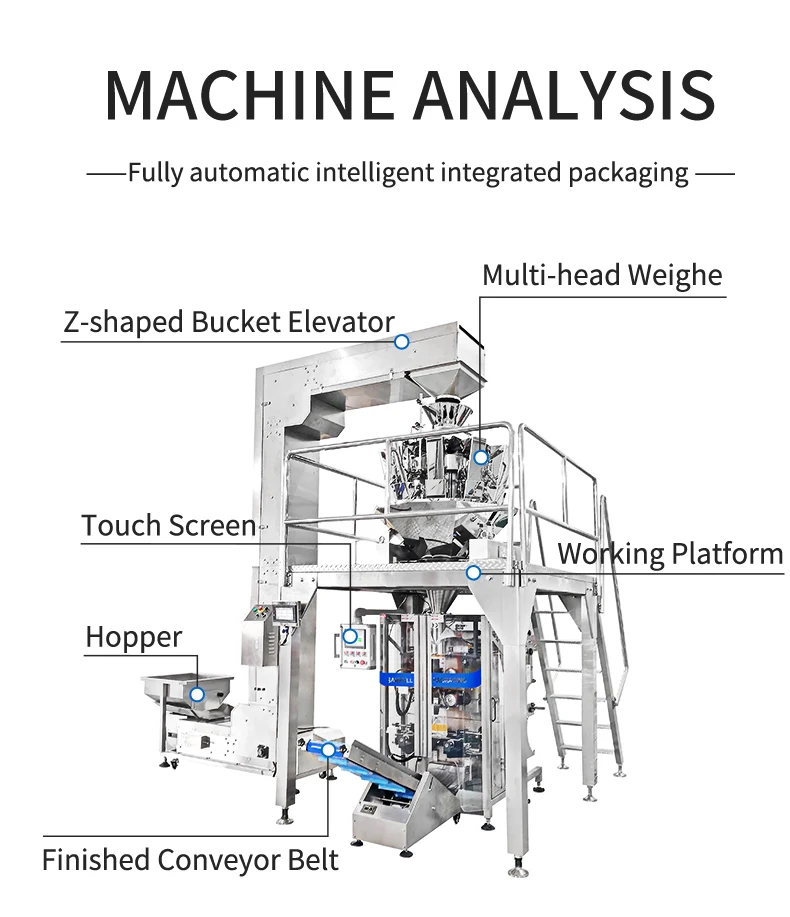

Structure of automatic vertical baler packing machine

Automatic vertical baler packing machine typically consists of a vertical chamber where the materials are fed. It utilizes hydraulic or mechanical mechanisms to compress the materials into tightly compacted bales. Once the desired compression level is achieved, the machine automatically ties or wraps the bale with straps or plastic wrapping.

Important parts of automatic vertical baler packing machine

The important components of the automatic vertical baler include the feeding system, metering system, packaging material supply system, and sealing system. These components work together to achieve an efficient and automated packaging process.

Automatic vertical baler packing machine customer case

| Application Scenario | Packaging Capacity | Packaging Size | Features |

| An Indonesian environmental protection company collects and packs waste metals (such as aluminum, copper, and steel) to improve transportation efficiency and reduce storage space. | Single machine processing capacity 5-10 tons/hour (depending on the type of metal) | Customized design, 600×400×300mm (adjustable) | Equipped with IoT control, automatic feeding and waste liquid collection functions; adopts anti-jamming design, suitable for high-density metal waste compression |

| A US clothing company uses it to compress clothing and knitted fabrics, reduce transportation volume, and reduce logistics costs | 500-1000 pieces/hour (depending on the thickness of the clothing) | 800×600×500mm (suitable for container transportation) | Vertical customized model to meet the packaging needs of different clothing; optimize the bundling method and improve the compactness of the package |

| A certain environmental protection plant in Pakistan is used to compress and pack waste paper and plastic bottles to improve recycling efficiency | 3-8 tons/hour (depending on the density of the material) | Standard packing block 500×400×300mm | Energy-saving and environmentally friendly design, reducing energy consumption by 30%; fully automatic operation, reducing manual intervention. |

1. Packaging Material

The type of material being packed determines compression force, machine durability, and safety features.

| Material Type | Key Considerations | Recommended Machine Features |

| Lightweight (e.g., textiles, foam, PET bottles) | Low density, easy to compress | Lower pressure (10-30 tons), fast cycle time |

| Medium Density (e.g., paper, cardboard, plastic film) | Moderate compression needed | 30-60 tons, adjustable pressure |

| Heavy/Dense (e.g., metal scraps, rubber, industrial waste) | High compression force required | 60-200+ tons, reinforced steel frame |

| Hazardous (e.g., medical waste, chemicals) | Leak-proof, corrosion-resistant | Stainless steel, sealed design |

2. Packaging Capacity

Required throughput (tons/hour or bales/hour) affects machine size and power.

| Capacity Range | Suitable Machine Size | Motor Power (kW) |

| < 1 ton/hour | Small baler (compact) | 5.5 - 11 kW |

| 1 - 5 tons/hour | Medium baler | 15 - 30 kW |

| > 5 tons/hour | Heavy-duty industrial baler | 37 - 75 kW |

3. Packaging Speed

| Application | Typical Cycle Time | Speed Optimization Tips |

| Slow, heavy compression (e.g., metal scraps) | 30-60 sec/bale | High-pressure hydraulic system |

| Medium-speed (e.g., cardboard, plastic) | 15-30 sec/bale | Dual-cylinder design |

| High-speed (e.g., textiles, foam) | 5-15 sec/bale | Servo-electric drive for faster cycles |

4. Packaging Dimensions

| Industry | Common Bale Size (mm) | Adjustability Needed? |

| Recycling (paper/plastic) | 500×400×300 - 800×600×500 | Yes (hydraulic adjustment) |

| Textile/Apparel | 600×500×400 - 1000×800×600 | Customizable |

| Metal Scraps | 400×300×200 - 600×500×400 | Fixed (high-density) |

Note: Some machines allow automated size adjustment via PLC control.

5. Bag Material

| Material<< /td> | Best For | Machine Compatibility |

| PP Woven Bags | Heavy materials (e.g., metal, construction waste) | Heavy-duty strapping system |

| PET/Plastic Film | Lightweight (e.g., PET bottles, foam) | Automatic film wrapping |

| Jute/Cotton Bags | Eco-friendly packaging | Manual or semi-auto loading |

| Steel Strapping | Extreme durability (e.g., scrap metal) | High-tension strapping head |

What is the price of a fully automatic vertical baler packaging machine?

The price of an automatic vertical baler varies greatly depending on factors such as brand, model, and functional configuration, and is generally between $540.00 and $12,000.00. The prices of automatic vertical balers of different models and functional configurations are also different. The more complex the functions and the higher the configuration, the higher the price of the automatic vertical baler. The price of a small automatic vertical baler is generally around tens of thousands of yuan, which is suitable for small enterprises or individual industrial and commercial households; the price of a medium-sized automatic vertical baler is generally around hundreds of thousands of yuan, which is suitable for medium-sized enterprises; the price of a large automatic vertical baler is generally around hundreds of thousands of yuan, which is suitable for large enterprises. If you have packaging needs, you can contact us directly. We can recommend the most suitable packaging equipment for you based on your own needs and packaging materials and provide a detailed quotation!

Why choose us as your automatic vertical baler packing machine supplier?

Xinxiang Dahan is a professional manufacturer of automatic vertical baler packing machine. They are committed to providing high-quality, efficient packaging solutions. Xinxiang Dahan's automatic vertical baler packing machine uses advanced technology and innovative design to quickly and accurately compress and pack various materials, such as cardboard, paper, plastic, etc. Their machines feature reliable performance and durable construction to cater to customers of varying sizes and needs. Xinxiang Dahan aims at customer satisfaction and provides customized solutions through cooperation and communication with customers to help customers improve production efficiency, reduce costs, and achieve sustainable packaging and recycling.