What is automatic liquid sachet packing machine?

Automatic liquid sachet packing machine is a specialized packaging machine that is designed to automatically fill and seal small sachets or pouches with liquid products. It is commonly used in industries such as food and beverage, pharmaceuticals, personal care, and household products.

Automatic liquid sachet packing machines offer several advantages, including high-speed operation, accurate filling, reliable sealing, efficient packaging, and improved productivity. They are designed to handle a wide range of liquid products, allowing businesses to package their products in convenient and portable sachets for retail or single-use purposes.

What are the applications of automatic liquid sachet packing machine?

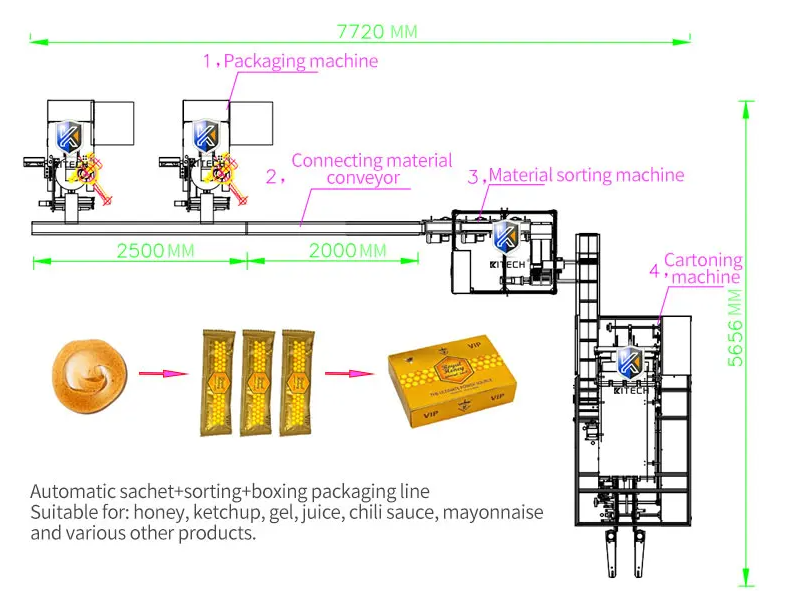

Automatic liquid sachet packing machine can be integrated into existing production lines or used as a standalone unit. It can be synchronized with other equipment, such as liquid pumps, conveyors, and labeling machines, for a fully automated packaging process.

How does automatic liquid sachet packing machine works?

Firstly, the sachets are fed into the machine, either manually or through an automatic feeding system. The machine then moves the sachets through different stations for filling, sealing, and cutting.

At the filling station, the liquid product is accurately measured and dispensed into each sachet. The machine may utilize volumetric fillers, piston fillers, or other mechanisms to ensure precise and consistent filling.

After filling, the sachets are transferred to the sealing station. Depending on the machine design, different sealing methods such as heat sealing or ultrasonic sealing may be employed to create a secure and leak-proof seal on the sachets.

Once sealed, the machine cuts the sachets individually or in groups, separating them for easy distribution and use. Some machines also include additional features like date coding or printing on the sachets for product identification and traceability.

The filled, sealed, and cut sachets are then discharged from the machine, ready for packaging or distribution.

Features of automatic liquid sachet packing machine

1.Efficiency and Productivity: The machine automates the packaging process, allowing for high-speed and consistent filling, sealing, and cutting of liquid sachets. This significantly increases production output and saves labor costs.

2.Accurate and Consistent Filling: The machine employs precise measurement systems to ensure accurate and consistent filling of liquid products into each sachet. This helps maintain product quality and reduces wastage.

3.Hygienic Packaging: The machine is designed to meet strict hygiene standards, minimizing the risk of contamination. It incorporates features like sterilization, clean-in-place (CIP) systems, and sanitary construction materials to ensure the integrity and safety of the packaged liquid products.

4.Versatility: Automatic liquid sachet packing machines can handle a wide range of liquid products, including beverages, sauces, oils, creams, gels, and more. They offer flexibility in packaging options, accommodating different sachet sizes and shapes.

Automatic liquid sachet packing machine specifications

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

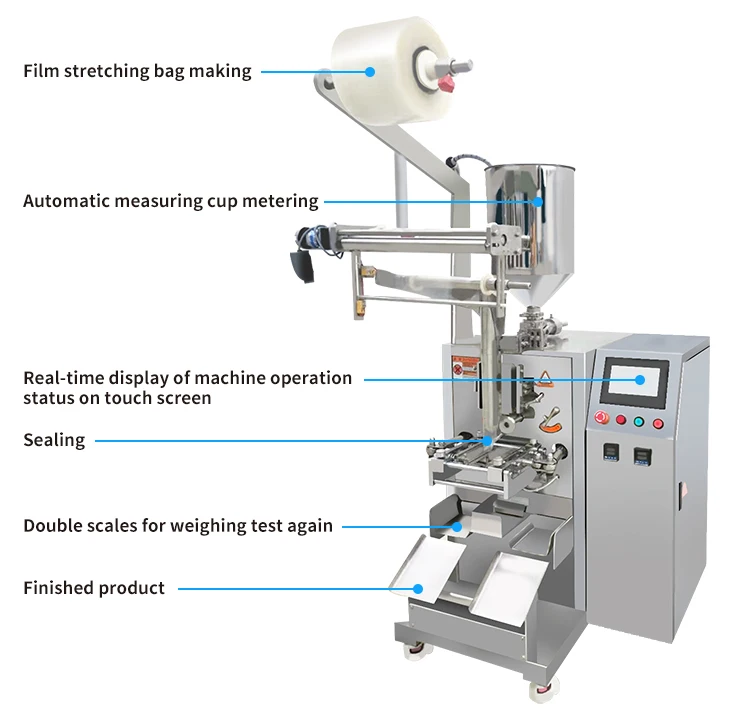

Structure of automatic liquid sachet packing machine

The structure of an automatic liquid sachet packing machine typically consists of a feeding system for sachets, a filling system for accurate liquid measurement and dispensing, a sealing system for creating secure and leak-proof seals, and a cutting system for separating the sachets. The machine is designed to automate the process of filling, sealing, and cutting liquid sachets, ensuring efficient and hygienic packaging of liquid products.

Customer case

![[field:title/]](/uploads/240111/1-240111155122530.jpg)